GENERALIZED FINITE DIFFERENCE METHOD FOR BENDING AND MODAL ANALYSIS OF FUNCTIONALLY GRADED CARBON NANOTUBE-REINFORCED COMPOSITE PLATES

-

摘要: 由复合材料构成的板结构一直以来受到很大关注, 其中功能梯度碳纳米管增强复合材料(functionally graded carbon nanotube-reinforced composite, FG-CNTRC)具有异常优越的力学性能, 使得诸多学者展开了对功能梯度碳纳米管增强复合材料板结构力学行为的研究. 本文以FG-CNTRC板为研究对象, 将一种新型的区域型无网格方法——广义有限差分法应用于求解基于一阶剪切变形的FG-CNTRC板结构的静态线性弯曲和自振模态问题. 广义有限差分法(generalized finite difference method, GFDM)基于函数的泰勒展开式和移动最小二乘法将计算区域中任意一子区域中心点处函数值的各阶偏导数表示成该支撑域节点上函数值的线性叠加. 该方法不仅无需网格划分和数值积分而且避免了全域无网格配点法通常遇到的病态稠密矩阵问题, 使得这类方法具有形式简单、易于应用和实现等优点, 目前广泛应用于各种科学和工程计算问题. 本文首先介绍了基于一阶剪切变形理论的功能梯度碳纳米管增强复合材料板的广义有限差分法离散模型. 随后通过基准算例, 检验了广义有限差分法的计算精度与收敛性. 最后数值分析和讨论了碳纳米管中不同分布型、体积分数、碳纳米管旋转角度、宽厚比、板倾斜角度和长宽比等对FG-CNTRC板结构弯曲和模态的影响.

-

关键词:

- 广义有限差分法 /

- 功能梯度碳纳米管增强复合材料 /

- 一阶剪切变形 /

- 板弯曲分析 /

- 模态分析

Abstract: Composite plates have always received much attention. In view of excellent mechanical properties of functionally graded carbon nanotube-reinforced composite (FG-CNTRC), it is particularly important to study the mechanical behavior of FG-CNTRC plates by scholars. Based on the first order shear deformation theory, a novel meshless collocation method, generalized finite difference method (GFDM), is applied to the bending and modal analysis of FG-CNTRC plates. Based on the multivariate Taylor series expansion and the moving least-squares theory, the partial derivatives of the underdetermined displacements at a certain node can be represented by a linear combination of the displacements of its neighboring nodes in the GFDM implementation. The proposed GFDM not only has the advantages of avoiding meshing generation and numerical integration, but also provides the sparse system, which overcomes the highly ill-conditioned assembled matrix issue existed in most of meshless collocation methods. Hence the method has advantages of simple-form, easy-to-use and -implement, which is generally used in a variety of scientific and engineering problems. The numerical model for the bending and modal analysis of FG-CNTRC plates in the GFDM implementation is firstly proposed. Then the computational validity and convergence of the GFDM are analysed by some benchmark cases. Finally, the influences of different distributional types, volume fraction, rotational angle of CNTs, inclination angle of plate, thickness to span ratio, length-width ratio and boundary conditions on the structural bending and modal are investigated in details. -

引 言

随着复合材料的发展, 纳米级材料已经成为诸多领域的研究热点, 其中表现出优越力学性能的一维碳纳米管在工程结构界逐渐受到人们的极大关注[1-3]. Shen[4]受到碳纳米管增强复合材料(carbon nanotube-reinforced composite, CNTRC)和功能梯度材料(functionally graded materials, FGMs)概念的启发, 提出并设计了功能梯度碳纳米管增强复合材料(functionally graded carbon nanotube-reinforced composite, FG-CNTRC)模型. 研究表明[4], 掺入少量碳纳米管增强体到结构基体中能够有效提高工程结构抗拉和抗压能力. 通过对碳纳米管纤维采取一定的梯度形式排布, 能够在纤维含量较低条件下合理高效地提升结构的宏观力学性能. 于是当FG-CNTRC被提出后, 有关功能梯度碳纳米管增强复合材料梁、板和壳结构的力学行为研究吸引了国内外诸多学者的注意[5-7].

目前已经有很多的数值分析方法对其从不同的角度做出了研究, 其中网格类数值离散[8-9]是理论和应用比较成熟的典型数值计算方法. 另一方面, 随着无网格与粒子类算法的快速发展[10-11], 其进一步摆脱了高质量网格的束缚和避免了高阶网格所需要的繁琐积分, 此类算法也被引入到功能梯度碳纳米管增强复合材料板结构的研究中. Lei等[12]采用Kp-Ritz无网格方法计算了4种CNTRC矩形板(uniform distribution (UD), functionally graded (FG)-V, FG-O, FG-X分布型)在横向均布荷载作用下的大挠度弯曲变形, 并给出了简支方板在不同碳纳米管分布形式下的荷载—挠度曲线. Do和Lee[13]基于高阶剪切变形理论(higher order shear deformation theory, HSDT)的径向点插值法(radial point interpolation method, RPIM)数值讨论了4种CNTRC矩形板的非线性弯曲问题.

广义有限差分法(generalized finite difference method, GFDM)[14-15]作为一种新型的强式无网格区域配点型方法, 以计算域内任意一点(中心点)为研究对象, 根据“最短距离”的准则在中心点附近形成该点的局部支撑域, 最后基于函数的泰勒展开式和移动最小二乘法将中心点处函数值的各阶偏导数表示成其支撑域节点上函数值的线性叠加. 该方法不仅无需网格划分和数值积分而且避免了全域无网格配点法通常遇到的病态稠密矩阵问题, 使得这类方法具有形式简单、易于应用和实现等优点. 其中Urena等[16-17]做出了突出贡献, 在2001年对影响广义有限差分法计算精度的各种因素, 如点簇形状、权函数选取、邻近点个数等进行了系统分析. 作为无网格粒子法中重要的数值计算方法, 该方法在各种力学问题中均得到了广泛应用. 2014年Fan等[18]将广义有限差分法用于求解稳定二维柯西反算问题以及双调和方程反算问题等; 后来也应用于求解复杂的瞬态热传导问题[19-20]. 2018年傅卓佳等[21-22]将广义有限差分法用于求解肿瘤热分析及Winkler板弯曲问题; 随后又将其应用于板结构声振耦合以及功能梯度材料板结构的弯曲问题[23-25].

目前功能梯度碳纳米管增强复合材料结构中涉及到碳纳米管转向问题的研究较少, 本文旨在应用广义有限差分法数值研究考虑了碳纳米管转向的FG-CNTRC板的弯曲及模态问题. 首先给出基于一阶剪切变形理论的功能梯度碳纳米管增强复合材料板的广义有限差分法离散模型. 随后通过基准算例, 检验广义有限差分法的计算精度与收敛性. 最后数值分析和讨论碳纳米管中不同分布型、体积分数、碳纳米管旋转角度、宽厚比、板倾斜角度、长宽比等对FG-CNTRC板结构弯曲和模态的影响.

1. 数学模型

1.1 控制方程

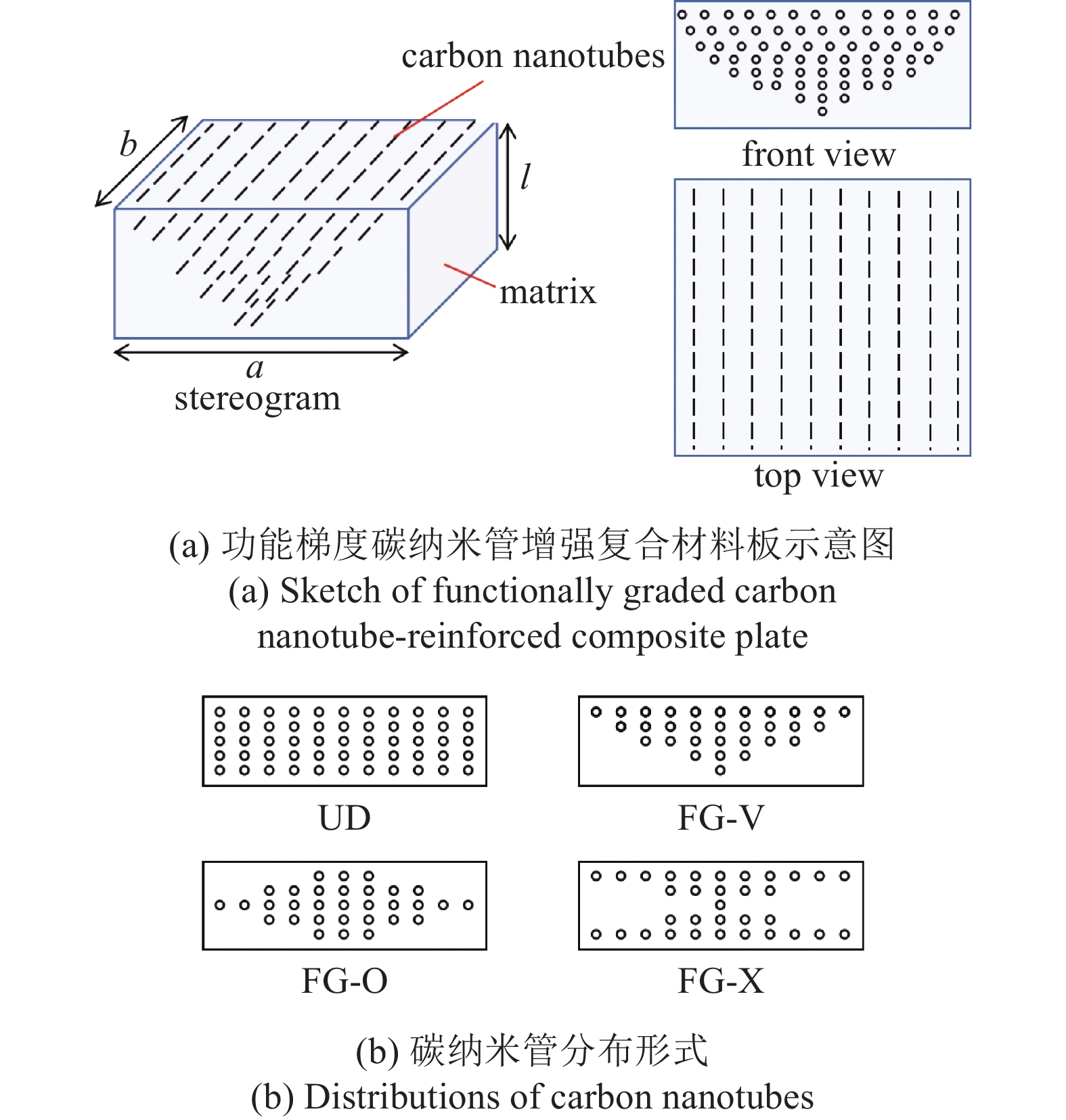

考虑一个由FG-V分布型的碳纳米管和基体材料共同组成的功能梯度碳纳米管增强复合材料矩形板, 如图1(a)所示, 长、宽、厚分别为

$ a $ ,$ b $ ,$ l $ , 以该矩形板中面建立$ x - y $ 坐标系,$ z $ 为板厚度方向的坐标. 如图1(b)所示, 常见的碳纳米管有4种分布形式, 为UD型、FG-V型、FG-O型、FG-X型, 其中UD型为均匀分布型, 其余为功能梯度分布型. 另外, 还有一种分布为FG-Λ型, 其与FG-V型成对称性分布, 在本质上是没有差异的, 所以在本文中只研究以上4种分布类型. 碳纳米管的体积分数$ {V_{{\text{CNT}}}} $ 可以表示为$$ {V_{{\text{CNT}}}} = \left\{ {\begin{array}{*{20}{l}} {V_{{\text{CNT}}}^*{\text{ }}\left( {{\text{UD}}} \right)} \\ {\left( {1 + \dfrac{{2z}}{l}} \right)V_{{\text{CNT}}}^*{\text{ }}\left( {{\text{FG - V}}} \right)} \\ {2\left( {1 - \dfrac{{2\left| z \right|}}{l}} \right)V_{{\text{CNT}}}^*{\text{ }}\left( {{\text{FG - O}}} \right)} \\ {2\left( {\dfrac{{2\left| z \right|}}{l}} \right)V_{{\text{CNT}}}^*{\text{ }}\left( {{\text{FG - X}}} \right)} \end{array}} \right. $$ (1) 式中,

$ V_{{\text{CNT}}}^* $ 是碳纳米管的质量体积分数, 通常有3种取值[8].为了表征功能梯度碳纳米管增强复合材料的宏观力学性能, Shen[4]提出的广义混合律模型在FG-CNTRC研究中广泛应用, 其考虑了碳纳米管的尺寸和温度依赖性, 并引入碳纳米管的效能参数作为FG-CNTRC的等效模型即

$$ \left. {\begin{array}{*{20}{l}} {{E_{11}} = {\eta _1}{V_{{\text{CNT}}}}E_{11}^{{\text{CNT}}} + {V_{\text{m}}}{E^{\text{m}}}} \\ {\dfrac{{{\eta _2}}}{{{E_{22}}}} = \dfrac{{{V_{{\text{CNT}}}}}}{{E_{22}^{{\text{CNT}}}}} + \dfrac{{{V_{\text{m}}}}}{{{E^{\text{m}}}}}} \\ {\dfrac{{{\eta _3}}}{{{G_{12}}}} = \dfrac{{{V_{{\text{CNT}}}}}}{{G_{12}^{{\text{CNT}}}}} + \dfrac{{{V_{\text{m}}}}}{{{G^{\text{m}}}}}} \\ {{V_{{\text{CNT}}}} + {V_{\text{m}}} = 1} \end{array}} \right\} $$ (2) 式中,

$ {\eta _j} $ 为碳纳米管的效能参数;$ E_{11}^{\text{*}} $ ,$ E_{22}^{\text{*}} $ 和$ G_{12}^{\text{*}} $ 为不同方向下材料的杨氏模量和剪切模量;$ {V_{\text{*}}} $ 为材料的体积分数(“CNT”代表“碳纳米管纤维”, “m”代表“基体”). 该模型存在一定的假设: 碳纳米管在基体中排列整齐, 且完全分散; 不考虑碳纳米管的长径比、波纹度等微观结构特征. 此后, Moradi-Dastjerdi等[26]引入额外的效能参数对模型进行修正, 考虑了碳纳米管的波纹度和长径比因素的影响, 其与Shen[4]提出的广义混合律模型基本相同.另外, 有关FG-CNTRC等效材料模型的其它一些物理参数定义如下[4]

$$ \;\;\;\rho = {V_{{\text{CNT}}}}{\rho _{{\text{CNT}}}} + {V_{\text{m}}}{\rho _{\text{m}}} $$ (3) $$ \left.\begin{array}{l} {\mu _{12}} = V_{{\text{CNT}}}^*\mu _{12}^{{\text{CNT}}} + {V_{\text{m}}}{\mu ^{\text{m}}} \hfill \\ {\mu _{21}} = \dfrac{{{E_{22}}}}{{{E_{11}}}}{\mu _{12}} \end{array} \right\}$$ (4) 式中,

$ \rho $ 为FG-CNTRC的等效密度,$ {\mu _{12}} $ 和$ {\mu _{21}} $ 为FG-CNTRC的等效泊松比,$ \mu _{12}^{{\text{CNT}}} $ 和$ {\mu ^{\text{m}}} $ 为碳纳米管和基体材料的泊松比.基于一阶剪切变形理论[24], 板的位移场

$ {\boldsymbol{U}} = {(u,v,w)^{\text{T}}} $ 为$$ \left. \begin{gathered} u\left( {x,y,z,t} \right) = {u_{\text{o}}}\left( {x,y,t} \right) + z{\phi _{{x}}}\left( {x,y,t} \right) \hfill \\ v\left( {x,y,z,t} \right) = {v_{\text{o}}}\left( {x,y,t} \right) + z{\phi _{{y}}}\left( {x,y,t} \right) \hfill \\ w\left( {x,y,z,t} \right) = {w_{\text{o}}}\left( {x,y,t} \right) \hfill \\ \end{gathered} \right\} $$ (5) 式中,

$ \left( {{u_{\text{o}}},{v_{\text{o}}},{w_{\text{o}}}} \right) $ 是板内任意一点在中面上的投影沿着$ \left( {x,y,z} \right) $ 方向的位移,$ \left( {{\phi _{{x}}},{\phi _{{y}}}} \right) $ 是变形后原中面法线的相应转动,$ t $ 为时间, 坐标$ z $ 为所考虑点到板中平面的距离.根据几何方程[24], 有应变和位移的关系式

$$\left. \begin{array}{l} {\boldsymbol{\varepsilon }} = {{\boldsymbol{\varepsilon }}^0} + z{{\boldsymbol{\varepsilon }}^1}\\ {\boldsymbol{\gamma }} = {{\boldsymbol{\gamma }}^0}\\ {{\boldsymbol{\varepsilon }}^0} = {( {\varepsilon _x^0}\quad{\varepsilon _y^0}\quad{\gamma _{xy}^0} )^{\text{T}}} = {( {{u_{{\text{o}},x}}}\quad{{v_{{\text{o}},y}}}\quad{{u_{{\text{o}},y}} + {v_{{\text{o}},x}}} )^{\text{T}}} \\ {{\boldsymbol{\varepsilon }}^1} = {( {\varepsilon _x^1}\quad{\varepsilon _y^1}\quad{\gamma _{xy}^1} )^{\text{T}}} = {( {{\phi _{x,x}}}\quad{{\phi _{y,y}}}\quad{{\phi _{x,y}} + {\phi _{y,x}}} )^{\text{T}}} \\ {{\boldsymbol{\gamma }}^0} = {( {\gamma _{xz}^0}\quad{\gamma _{yz}^0} )^{\text{T}}} = {( {{\phi _x} + {w_{{\text{o}},x}}}\quad{{\phi _y} + {w_{{\text{o}},y}}} )^{\text{T}}} \end{array} \right\}$$ (6) 对于FG-CNTRC板结构, 其物理方程[8]为

$$ \left.\begin{array}{l} {\sigma _x} = {E_{11}}({\varepsilon _x} + {\mu _{21}}{\varepsilon _y})/(1 - {\mu _{12}}{\mu _{21}}) \hfill \\ {\sigma _y} = {E_{22}}({\varepsilon _y} + {\mu _{12}}{\varepsilon _x})/(1 - {\mu _{12}}{\mu _{21}}) \hfill \\ {\tau _{xy}} = {G_{12}}{\gamma _{xy}},{\text{ }}{\tau _{xz}} = {G_{23}}{\gamma _{xz}},{\text{ }}{\tau _{yz}} = {G_{13}}{\gamma _{yz}} \end{array} \right\}$$ (7) 根据内力与应力的关系[24], 有

$$\left. \begin{array}{l} {\boldsymbol{N}} = {( {{N_x}}\quad{{N_y}}\quad{{N_{xy}}} )^{\text{T}}} = \displaystyle\int_{ - l/2}^{l/2} {{{( {{\sigma _x}}\quad{{\sigma _y}}\quad{{\tau _{xy}}} )}^{\text{T}}}} {\rm{d}}z \hfill \\ {\boldsymbol{M}} = {( {{M_x}}\quad{{M_y}}\quad{{M_{xy}}} )^{\text{T}}} = \displaystyle\int_{ - l/2}^{l/2} {z{{( {{\sigma _x}}\quad{{\sigma _y}}\quad{{\tau _{xy}}} )}^{\text{T}}}} {\rm{d}}z \hfill \\ {\boldsymbol{Q}} = {( {{Q_x}}\quad{{Q_y}} )^{\text{T}}} = \displaystyle\int_{ - l/2}^{l/2} {{{( {{\tau _{xz}}}\quad{{\tau _{yz}}} )}^{\text{T}}}} {\rm{d}}z \end{array} \right\}$$ (8) 将式(7)代入式(8)有

$$\left. \begin{array}{l} \left[ {\begin{array}{*{20}{c}} {\boldsymbol{N}} \\ {\boldsymbol{M}} \end{array}} \right] = \left[ {\begin{array}{*{20}{c}} {\boldsymbol{A}}&{\boldsymbol{B}} \\ {\boldsymbol{B}}&{\boldsymbol{C}} \end{array}} \right]\left[ {\begin{array}{*{20}{c}} {{{\boldsymbol{\varepsilon }}^0}} \\ {{{\boldsymbol{\varepsilon }}^1}} \end{array}} \right] \hfill \\ {\boldsymbol{Q}} = {{{\boldsymbol{A}}_{{1}}}} {{{\boldsymbol{\gamma }}^0}} \end{array} \right\}$$ (9) 其中

$$ {\boldsymbol{A}} = \left[ {\begin{array}{*{20}{c}} {{A_{11}}}&{{A_{12}}}&{{A_{16}}} \\ {{A_{12}}}&{{A_{22}}}&{{A_{26}}} \\ {{A_{16}}}&{{A_{26}}}&{{A_{66}}} \end{array}} \right]{\text{, }}{\boldsymbol{B}} = \left[ {\begin{array}{*{20}{c}} {{B_{11}}}&{{B_{12}}}&{{B_{16}}} \\ {{B_{12}}}&{{B_{22}}}&{{B_{26}}} \\ {{B_{16}}}&{{B_{26}}}&{{B_{66}}} \end{array}} \right], $$ $$ {\boldsymbol{C}} = \left[ {\begin{array}{*{20}{c}} {{C_{11}}}&{{C_{12}}}&{{C_{16}}} \\ {{C_{12}}}&{{C_{22}}}&{{C_{26}}} \\ {{C_{16}}}&{{C_{26}}}&{{C_{66}}} \end{array}} \right]{\text{, }}{{\boldsymbol{A}}_{{1}}} = \chi \left[ {\begin{array}{*{20}{c}} {{A_{44}}}&{{A_{45}}} \\ {{A_{45}}}&{{A_{55}}} \end{array}} \right] $$ $$ \left( {{A_{ij}},{B_{ij}},{C_{ij}}} \right) = \int_{ - l/2}^{l/2} {\overline {{\psi _{ij}}} (1,z,{z^2}){\rm{d}}z} $$ 式中,

$ {\boldsymbol{A}} $ ,$ {\boldsymbol{B}} $ 和$ {\boldsymbol{C}} $ 分别表示拉伸、耦合以及弯曲刚度矩阵,${{\boldsymbol{A}}_{{1}}}$ 为剪切刚度矩阵,$ \chi $ 为一阶剪切因子, 对于矩形截面一般有$ \chi = 5/6 $ .接下来考虑如图2所示的碳纳米管转向问题[27], 对式(9)中的

$ \overline {{\psi _{ij}}} $ 有如下坐标变换关系$$\left. \begin{array}{l} \overline {\boldsymbol{\psi }} {\boldsymbol{ = \varLambda \psi }}{{\boldsymbol{\varLambda }}^{\rm{T}}}\\ \overline {\boldsymbol{\psi }} = \left[ {\begin{array}{*{20}{c}} {{{\overline \psi }_{11}}}&{{{\overline \psi }_{12}}}&{{{\overline \psi }_{16}}}&0&0 \\ {{{\overline \psi }_{12}}}&{{{\overline \psi }_{22}}}&{{{\overline \psi }_{26}}}&0&0 \\ {{{\overline \psi }_{16}}}&{{{\overline \psi }_{26}}}&{{{\overline \psi }_{66}}}&0&0 \\ 0&0&0&{{{\overline \psi }_{44}}}&{{{\overline \psi }_{45}}} \\ 0&0&0&{{{\overline \psi }_{45}}}&{{{\overline \psi }_{55}}} \end{array}} \right]\\ \begin{array}{l} {\boldsymbol{\varLambda }} =\\ \left[ {\begin{array}{*{20}{c}} {{{\cos }^2}\beta }&{{{\sin }^2}\beta }&{ - 2\cos \beta \sin \beta }&0&0 \\ {{{\sin }^2}\beta }&{{{\cos }^2}\beta }&{2\cos \beta \sin \beta }&0&0 \\ {\cos \beta \sin \beta }&{ - \cos \beta \sin \beta }&{{{\cos }^2}\beta - {{\sin }^2}\beta }&0&0 \\ 0&0&0&{\cos \beta }&{ - \sin \beta } \\ 0&0&0&{\sin \beta }&{\cos \beta } \end{array}} \right] \end{array}\\ {\boldsymbol{\psi }} = \left[ {\begin{array}{*{20}{c}} {{\psi _{11}}}&{{\psi _{12}}}&0&0&0 \\ {{\psi _{12}}}&{{\psi _{22}}}&0&0&0 \\ 0&0&{{\psi _{66}}}&0&0 \\ 0&0&0&{{\psi _{44}}}&0 \\ 0&0&0&0&{{\psi _{55}}} \end{array}} \right] \end{array} \right\}$$ (10) 其中,

$ {\boldsymbol{\varLambda }} $ 为坐标旋转变换矩阵;$ \beta $ 为碳纳米管旋转角度, 如图2所示;$ {\boldsymbol{\psi }} $ 为碳纳米管横向布置时的FG-CNTRC物理关系矩阵, 有如下定义$$ \left. \begin{array}{l} {\psi _{11}} = {E_{11}}/(1 - {\mu _{12}}{\mu _{21}}) \hfill \\ {\psi _{22}} = {E_{22}}/(1 - {\mu _{12}}{\mu _{21}}) \hfill \\ {\psi _{12}} = {\mu _{21}}{E_{11}}/(1 - {\mu _{12}}{\mu _{21}}) \hfill \\ {\psi _{66}} = {G_{12}},{\text{ }}{\psi _{44}} = {G_{23}},{\text{ }}{\psi _{55}} = {G_{13}} \end{array} \right\} $$ (11) 式中, 针对第三方向相关的剪切模量满足

$$ {G_{12}} = {G_{13}} = {G_{23}} $$ 最后, 根据Hamilton变分原理[8], 结合式(8)导出FG-CNTRC板模型的运动微分方程

$$ \left. \begin{array}{l} {N_{x,x}} + {N_{xy,y}} = {I_0}{u_{{\text{o}},tt}} + {I_1}{\phi _{x,tt}} \hfill \\ {N_{xy,x}} + {N_{y,y}} = {I_0}{v_{{\text{o}},tt}} + {I_1}{\phi _{y,tt}} \hfill \\ {Q_{x,x}} + {Q_{y,y}} + q = {I_0}{w_{{\text{o}},tt}} \hfill \\ {M_{x,x}} + {M_{xy,y}} - {Q_x} = {I_1}{u_{{\text{o}},tt}} + {I_2}{\phi _{x,tt}} \hfill \\ {M_{xy,x}} + {M_{y,y}} - {Q_y} = {I_1}{v_{{\text{o}},tt}} + {I_2}{\phi _{y,tt}} \end{array} \right\} $$ (12) 式中,

$ q $ 为板平面上的横向荷载集度$ q(x,y) $ ,$({I_0},{I_1},{I_2}) $ 有如下定义$$ ({I_0},{I_1},{I_2}) = \int_{ - l/2}^{l/2} {\rho (1,z,{z^2}){\rm{d}}z} $$ 1.2 边界条件

对于板结构, 常见的边界条件有以下3种:

(1) 固支边界(clamped, C)

$$ {u_n} = {u_s} = w = {\phi _n} = {\phi _s} = 0 $$ (13) (2) 简支边界(simply, S)

$$ {u_n} = {u_s} = w = {\phi _s} = {M_n} = 0 $$ (14) (3) 自由边界(free, F)

$$ {N_n} = {N_s} = {M_n} = {M_s} = {V_n} = 0 $$ (15) 2. 广义有限差分法

考虑一个二维问题计算域

$ \varOmega (x,y) $ , 如图3所示对任意一个离散节点$ {x_o} $ 形成一个包含$ s $ 点数的点簇(支撑域), 对应函数值$ {w_j} $ 的4阶泰勒展开为$$ \begin{split} {w_j} = &{w_o} + hw_o^x + kw_o^y + \frac{{{h^2}}}{2}w_o^{xx} + hkw_o^{xy} + \hfill \\ & \frac{{{k^2}}}{2}w_o^{yy} + ... + \frac{{h{k^3}}}{6}w_o^{xyyy} + \frac{{{k^4}}}{{24}}w_o^{yyyy} + O({r^5}) \end{split} $$ (16) 式中,

$ h $ 为点$ {x_j} $ 与点$ {x_o} $ 的横轴距离,$ k $ 为点$ {x_j} $ 与点$ {x_o} $ 的纵轴距离,$ O({r^5}) $ 为高阶余项,$ r $ 为$ {x_j} $ 与$ {x_o} $ 的欧几里得距离.对于点簇展开后的余项可定义残差函数

$$ \begin{split} {{\varTheta }}(w) =& \sum\limits_{j = 1}^s {\left[ {\left( {{w_o} - {w_j} + {h_j}w_o^x + {k_j}w_o^y + \frac{{h_j^2}}{2}w_o^{xx} + } \right.} \right.} \\ & {\left. {\left. {{h_j}{k_j}w_o^{xy} + \frac{{k_j^2}}{2}w_o^{yy} + ... + \frac{{k_j^4}}{{24}}w_o^{yyyy}} \right){\omega _j}} \right]^2} \end{split}$$ (17) 其中,

$ {\omega _j} $ 表示在该“点簇”中点$ {x_j} $ 处的加权系数. 采用式(18)所示的四次样条权函数, 其具有3阶连续性, 且满足单位性、紧支性和对称性条件[16]$$ {\omega _j} = \left\{ {\begin{array}{*{20}{l}} {1 - 6{{\overline {{r_j}} }^2} + 8{{\overline {{r_j}} }^3} - 3{{\overline {{r_j}} }^4},\;\;{\text{ }}\overline {{r_j}} \leqslant 1} \\ {0,\;\;{\text{ }}\overline {{r_j}} > 1} \end{array}} \right. $$ (18) 式中

$ \overline {{r_j}} = {r_j}/{r_\omega } $ ,$ {r_\omega } $ 为权函数支撑域的尺寸.为了方便, 定义

$$ {{\boldsymbol{D}}_{\rm{w}}} = {\left[ {\begin{array}{*{20}{c}} {w_o^x}&{w_o^y}&{w_o^{xx}}& \cdots &{w_o^{xyyy}}&{w_o^{yyyy}} \end{array}} \right]^{\text{T}}} $$ 通过求极值使得残差函数

$ {{\varTheta }}(w) $ 最小化, 对${{\boldsymbol{D}}_{\rm{w}}}$ 中的每一项进行变分, 形成如下矩阵$$ {\boldsymbol{ H}}{{\boldsymbol{D}}_{\rm{w}}}{\boldsymbol{ = R}} $$ (19) $$ {\boldsymbol{H}} = {\left[ {\begin{array}{*{20}{c}} {\Sigma \omega _j^2h_j^2}&{\Sigma \omega _j^2{h_j}{k_j}}&{\Sigma \omega _j^2h_j^3/2}&{\begin{array}{*{20}{c}} \cdots &{\Sigma \omega _j^2h_j^2k_j^3/6}&{\Sigma \omega _j^2{h_j}k_j^4/24} \end{array}} \\ {}&{\Sigma \omega _j^2k_j^2}&{\Sigma \omega _j^2h_j^2{k_j}/2}&{\begin{array}{*{20}{c}} \cdots &{\Sigma \omega _j^2{h_j}k_j^4/6}&{\Sigma \omega _j^2k_j^5/24} \end{array}} \\ {}&{}&{\Sigma \omega _j^2h_j^3/4}&{\begin{array}{*{20}{c}} \cdots &{\Sigma \omega _j^2h_j^2k_j^3/12}&{\Sigma \omega _j^2{h_j}k_j^4/48} \end{array}} \\ {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} \vdots \\ {} \end{array}} \\ {\rm{S}} \end{array}}&{\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} \vdots \\ {} \end{array}} \\ {\rm{ Y }} \end{array}}&{\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} \vdots \\ {} \end{array}} \\ {\rm{ M }} \end{array}}&{\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} \ddots \\ \cdots \end{array}} \\ \cdots \end{array}}&{\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} \vdots \\ {\Sigma \omega _j^2h_j^2k_j^6/36} \end{array}} \\ \cdots \end{array}}&{\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} \vdots \\ {\Sigma \omega _j^2{h_j}k_j^7/144} \end{array}} \\ {\Sigma \omega _j^2k_j^8/576} \end{array}} \end{array}} \end{array}} \right]_{14 \times 14}} $$ $$ {\boldsymbol{R}} = {\left[ {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} { - {w_o}\Sigma \omega _j^2{h_j} + \Sigma {w_j}\omega _j^2{h_j}} \\ { - {w_o}\Sigma \omega _j^2{k_j} + \Sigma {w_j}\omega _j^2{k_j}} \end{array}} \\ { - {w_o}\Sigma \omega _j^2h_j^2/2 + \Sigma {w_j}\omega _j^2h_j^2/2} \end{array}} \\ \vdots \\ { - {w_o}\Sigma \omega _j^2{h_j}k_j^3/6 + \Sigma {w_j}\omega _j^2{h_j}k_j^3/6} \\ { - {w_o}\Sigma \omega _j^2k_j^4/24 + \Sigma {w_j}\omega _j^2k_j^4/24} \end{array}} \right]_{14 \times 1}} $$ 其中,

$ {\boldsymbol{H}} $ 是由点与点之间的距离分量以及权函数所形成的具有对称性的系数矩阵, “S, Y, M”表示其具有上三角矩阵对称性,$ {\boldsymbol{R}} $ 是距离分量、权函数以及未知点函数值所形成的右端矩阵. 为保证矩阵$ {\boldsymbol{H}} $ 的可逆性, 研究表明[18-19,22]在二维计算中, 支撑域点数一般满足两倍的泰勒展开项数.对式(19)的线性方程组进行求解, 有

$$ {{\boldsymbol{D}}_{\rm{w}}} = \left[ {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {w_o^x} \\ {w_o^y} \end{array}} \\ {w_o^{xx}} \end{array}} \\ \vdots \\ {w_o^{xyyy}} \\ {w_o^{yyyy}} \end{array}} \right] = \left[ {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {\alpha _o^{x,o}w_o^o + \displaystyle\sum\limits_{j = 1}^s {\alpha _j^{x,o}w_j^o} } \\ {\alpha _o^{y,o}w_o^o + \displaystyle\sum\limits_{j = 1}^s {\alpha _j^{y,o}w_j^o} } \end{array}} \\ {\alpha _o^{xx,o}w_o^o + \displaystyle\sum\limits_{j = 1}^s {\alpha _j^{xx,o}w_j^o} } \end{array}} \\ \vdots \\ {\alpha _o^{xyyy,o}w_o^o + \displaystyle\sum\limits_{j = 1}^s {\alpha _j^{xyyy,o}w_j^o} } \\ {\alpha _o^{yyyy,o}w_o^o + \displaystyle\sum\limits_{j = 1}^s {\alpha _j^{yyyy,o}w_j^o} } \end{array}} \right] $$ (20) 式中,

$ w_j^o $ 表示以中心点$ {x_o} $ 所形成“点簇”内点$ {x_j} $ 处的未知函数值,$ \alpha _j^{xyyy,o} $ 表示以中心点$ {x_o} $ 所形成“点簇”内点$ {x_j} $ 处的已知系数(与点距离及权函数有关), 其刻画了该中心点$ {x_o} $ 处的任意偏导项由其相邻节点(邻近点)处函数值的线性组合来近似表示.令计算域中的节点满足控制方程式(12), 边界节点满足边界条件式(13) ~ 式(15), 可得到仅含离散点未知物理量的线性方程组, 从而获得问题的数值解. 因权函数的连续性, 每个节点携带了相邻近节点的物理信息, 使得对节点形成移动的带权局部支撑域能够保证全域数值解的协调性[16].

对于控制方程式(12)所形成的FG-CNTRC板结构弯曲问题, 最终可得到总体线性方程组

$$ {\boldsymbol{KU = F}} $$ (21) 其中,

$ {\boldsymbol{K}} $ 为总体刚度矩阵,$ {\boldsymbol{F}} $ 为荷载列阵,$ {\boldsymbol{U}} $ 为待求的中面位移及转角向量.对于控制方程式(12)所形成的FG-CNTRC板结构模态问题, 运用模态分析法[23]得到振型微分方程的矩阵表达

$$\left.\begin{array}{l} {\boldsymbol{K\varPsi = }}{\varpi ^2}{\boldsymbol{M\varPsi }}\\ {\boldsymbol{M}} = \left[ {\begin{array}{*{20}{c}} {{{\boldsymbol{\delta }}I_0}}&{}&{}&{{{\boldsymbol{\delta }}I_1}}&{} \\ {}&{{{\boldsymbol{\delta }}I_0}}&{}&{}&{{{\boldsymbol{\delta }}I_1}} \\ {}&{}&{{{\boldsymbol{\delta }}I_0}}&{}&{} \\ {{{\boldsymbol{\delta }}I_1}}&{}&{}&{{{\boldsymbol{\delta }}I_2}}&{} \\ {}&{{{\boldsymbol{\delta }}I_1}}&{}&{}&{{{\boldsymbol{\delta }}I_2}} \end{array}} \right],\;\; {\boldsymbol{\varPsi }} = \left[ {\begin{array}{*{20}{c}} u \\ v \\ w \\ {{\phi _x}} \\ {{\phi _y}} \end{array}} \right] \end{array} \right\}$$ (22) 式中,

$ {\boldsymbol{K}} $ 表示由广义有限差分法形成的整体刚度矩阵,$ {\boldsymbol{M}} $ 为由式(12)构建的整体质量矩阵,${\boldsymbol{\delta}}$ 表示大小为板结构离散节点数下的单位矩阵,$ \varpi $ 表示FG-CNTRC板自由振动的自然频率;$ {\boldsymbol{\varPsi }} $ 表示由每个节点组成的振型列阵.需要注意的是, 基于一阶剪切变形理论的FG-CNTRC板模型控制方程是一个最高阶为二阶的偏微分方程组, 而本文采用4阶泰勒展开式的广义有限差分法对该控制方程进行离散, 目的是更进一步地提高计算精度(减小余项残差)和扩大广义有限差分法在更多问题中的适用性.

3. 数值结果与讨论

本节首先以各向同性板结构弯曲的计算实例讨论广义有限差分法这一算法特性, 接着运用广义有限差分法对含碳纳米管转向的FG-CNTRC板的静态线性弯曲和自振模态问题进行数值分析与讨论.

3.1 各向同性板结构模型验证

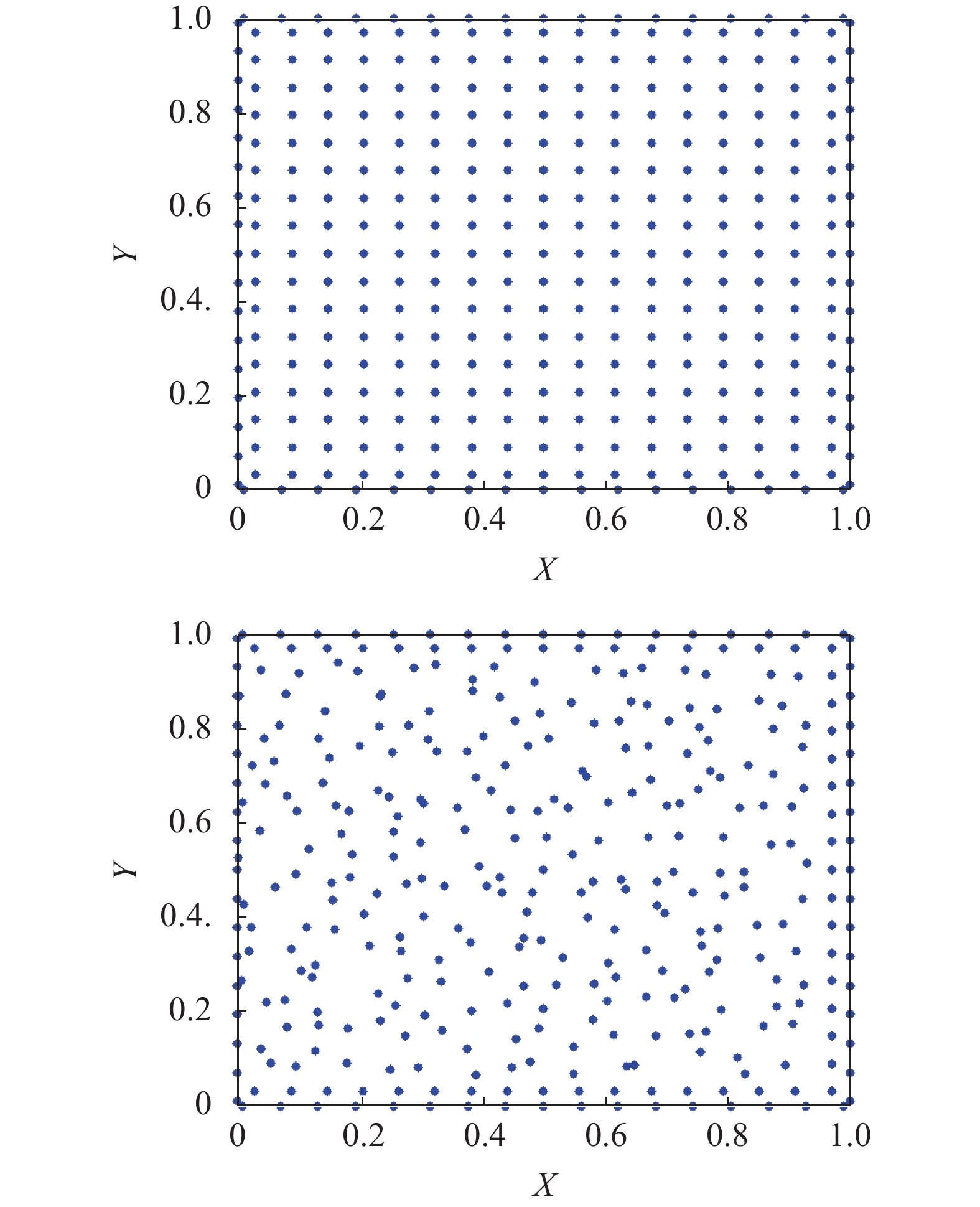

以各向同性均质板模型为例, 图4(a)展示了在相同运行环境下用广义有限差分法(GFDM)和传统有限单元法(traditional finite element method, TFEM)计算厚跨比为0.1的四周固支方形板弯曲问题. 图4(b)讨论了GFDM中不同邻近点数对数值结果的影响. 基于图5展示的混乱布点模型, 与不同厚跨比下的解析解[28]进行了比较, 表1展示了不同厚跨比下GFDM均匀布点与散乱布点的相对误差. 可以看出广义有限差分法的数值计算在任意混乱布点下, 计算精度稍有所降低, 但仍能得到满意的结果. 其无需网格和繁琐的数值积分, 仅通过散乱的节点信息便可进行计算, 具有更高的计算收敛性和稳定性.

表 1 相对误差Table 1. Relative errorThickness ratio $ l/a $ Relative error/% Uniform nodes Scattered nodes 0.10 0.022 0.070 0.15 0.014 0.044 0.20 0.046 0.061 0.25 0.018 0.018 0.30 0.010 0.016 0.35 0.015 0.030 对于一阶剪切变形理论的中厚板问题, 当板变得比较薄时, 因剪切应变能过大产生错误的结果, 这种现象称为剪切自锁[29]. 在无网格GFDM中, 通过提高泰勒展开的阶次来构造节点的支撑域, 能够简单有效地避免剪切自锁现象的发生. 如图6所示, 采用6阶展开项能够有效避免剪切自锁的发生, 相较与在有限元中采用缩减积分法、假设剪切应变法等[28], 其简单高效地提高了求解方法的通用性.

3.2 FG-CNTRC板结构及等效模型参数

如图1所示的FG-CNTRC板结构模型, 根据Shen[4]提出的广义混合律模型, 用于计算的FG-CNTRC等效模型参数如表2和表3所示.

表 2 材料属性Table 2. Material propertiesEquivalent parameters of reinforced-CNTs Matrix materials $ \begin{gathered} E_{11}^{{\text{CNT}}} = 5.6466{\text{ TPa}} \end{gathered} $ $ \begin{gathered} {E^{\text{m}}} = 2.1{\text{ GPa}} \end{gathered} $ $ \begin{gathered} E_{22}^{{\text{CNT}}} = 7.0800{\text{ TPa}} \end{gathered} $ $ \begin{gathered} {\rho ^{\text{m}}} = 1150{\text{ kg/}}{{\text{m}}^{\text{3}}} \end{gathered} $ $ \begin{gathered} G_{12}^{{\text{CNT}}} = 1.9447{\text{ TPa}} \end{gathered} $ $ \begin{gathered} {\mu ^{\text{m}}} = 0.34 \end{gathered} $ $ \begin{gathered} {\rho ^{{\text{CNT}}}} = 1400{\text{ kg/}}{{\text{m}}^{\text{3}}} \end{gathered} $ $ \begin{gathered} {G^{\text{m}}} = {E^{\text{m}}}/\left[ {2(1 + {\mu ^{\text{m}}})} \right] \end{gathered} $ $ \begin{gathered} \mu _{12}^{{\text{CNT}}} = 0.175\end{gathered} $ 表 3 碳纳米管的效能参数Table 3. Efficiency parameters of CNTs$ V_{{\text{CNT}}}^{\text{*}} $ $ {\eta _1} $ $ {\eta _2} $ $ {\eta _3} $ 0.11 0.149 0.934 0.934 0.14 0.150 0.941 0.941 0.17 0.149 1.381 1.381 3.3 弯曲分析

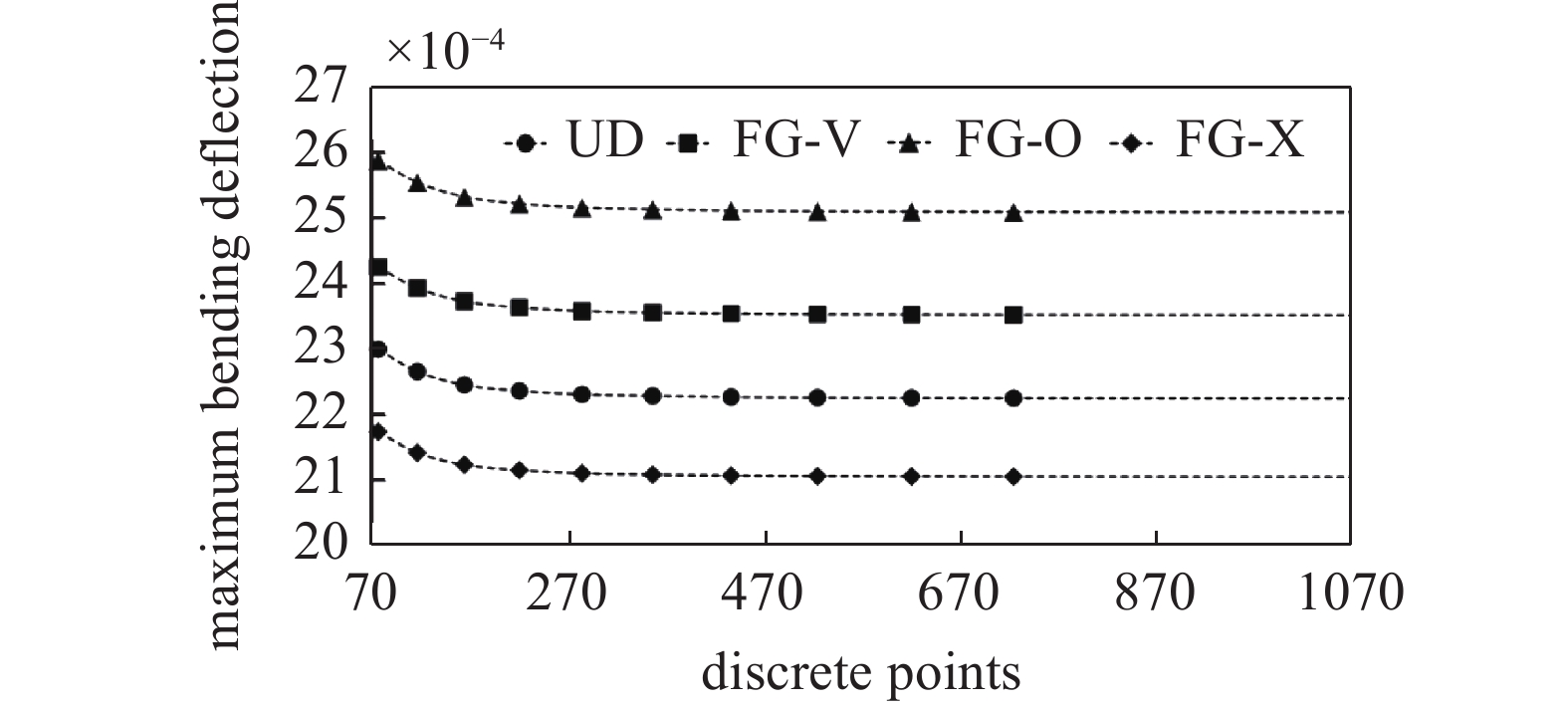

首先在没有考虑碳纳米管转向的情况下, 表4计算了体积分数为0.11, 不同分布型下的四周固支FG-CNTRC板的弯曲变形, 并与已有文献Zhu等[8]的数值结果进行了参考比较, 两者都能很好地近似, 说明基于一阶剪切变形板理论的广义有限差分法求解FG-CNTRC板弯曲问题的计算正确和有效性. 图7为体积分数为0.11, 宽厚比

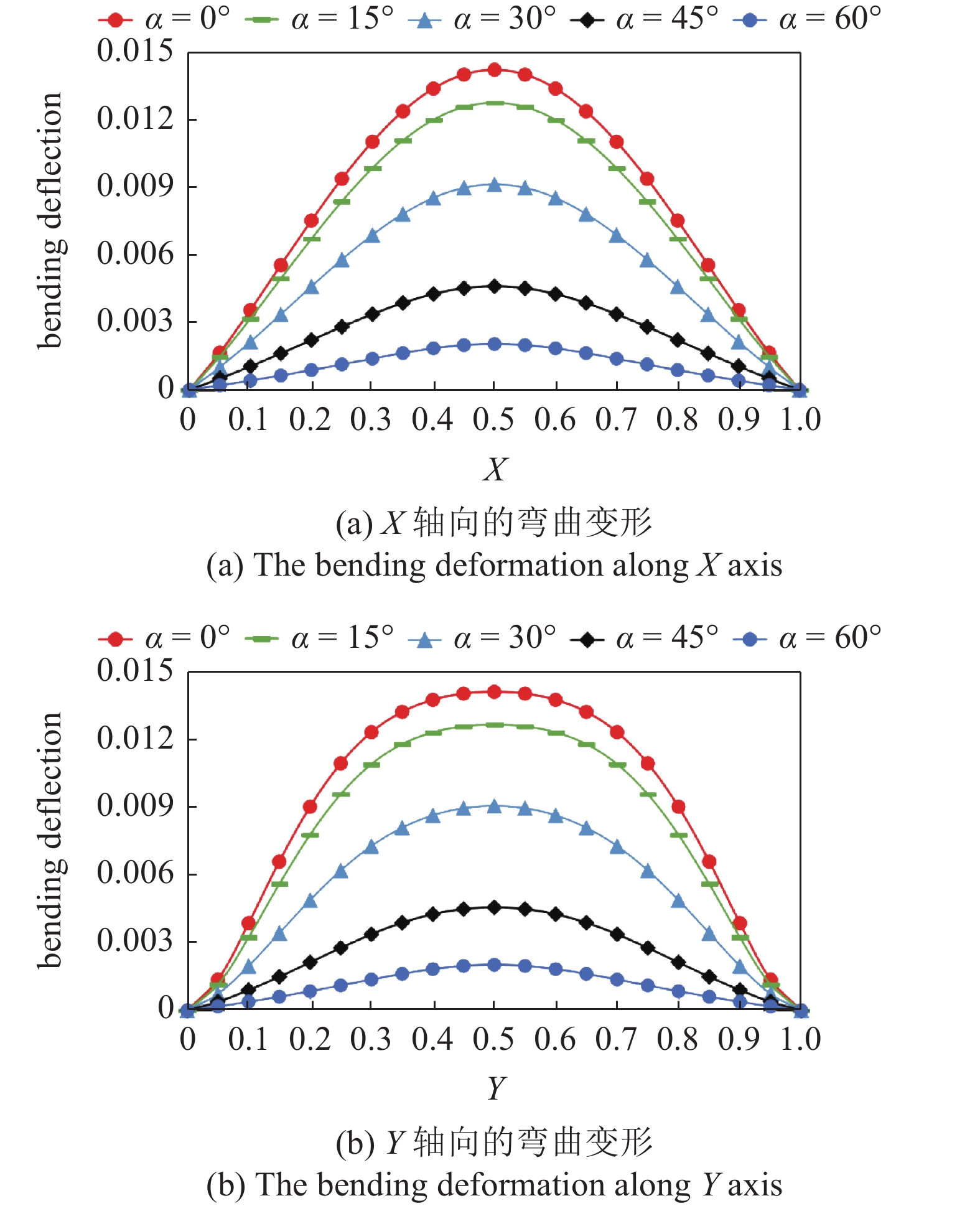

$ a/l = 10 $ , 四周固支FG-CNTRC板中心弯曲随离散点增加的收敛情况, 在总点数达到300左右时结果近乎收敛, 能够看出广义有限差分法具有计算快、收敛稳定的特性.表 4 四周固支FG-CNTRC板的中心弯曲$ w/l $ Table 4. The center bending$ w/l $ of FG-CNTRC plate with all clamped boundaries$ a/l $ Distributions FEM[8] GFDM 10 UD 2.227 × 10−3 2.222 × 10−3 FG-V 2.351 × 10−3 2.349 × 10−3 FG-O 2.506 × 10−3 2.505 × 10−3 FG-X 2.104 × 10−3 2.103 × 10−3 20 UD 1.338 × 10−2 1.337 × 10−2 FG-V 1.591 × 10−2 1.591 × 10−2 FG-O 1.856 × 10−2 1.858 × 10−2 FG-X 1.150 × 10−2 1.149 × 10−2 50 UD 0.2618 0.2626 FG-V 0.3653 0.3657 FG-O 0.4719 0.4721 FG-X 0.1900 0.1906 图8展示了含碳纳米管转向的FG-CNTRC板随倾斜角

$ \alpha $ 变化的各向异性弯曲状态($ \beta = - \alpha $ ), 分别从X轴向和Y轴向描述了该板的弯曲变形. 碳纳米管具有指向性使得在X和Y方向上存在着各向异性的刚度变化. 图9展示了厚跨比为0.1的四周固支FG-CNTRC板在荷载$ q = 0.1\;{\text{MPa}} $ 下中心点处的$ \sigma $ 应力, 可以看出UD型、FG-O型和FG-X分布型下的CNTRC板应力与$ z = 0 $ 成中心对称, 即$ z = 0 $ 为该FG-CNTRC板的中性层, 原因是UD型、FG-O型和FG-X型碳纳米管分布呈对称性分布. 对于没有横向对称性的FG-V碳纳米管分布型, 板结构中性层大概在$ z = 0.15 $ . 且$ {\sigma _{xx}} $ 与$ {\sigma _{yy}} $ 应力大小不等, 沿厚度方向变化情况也不相同, 正因如此使得FG-CNTRC板在宏观上具有如图8所示的各向异性弯曲状态.3.4 自振频率分析

下面运用广义有限差分法对含碳纳米管转向的FG-CNTRC板的自振模态问题进行详细分析与讨论. 表5展示了不同分布型下四周固支FG-CNTRC板的前6阶自振频率

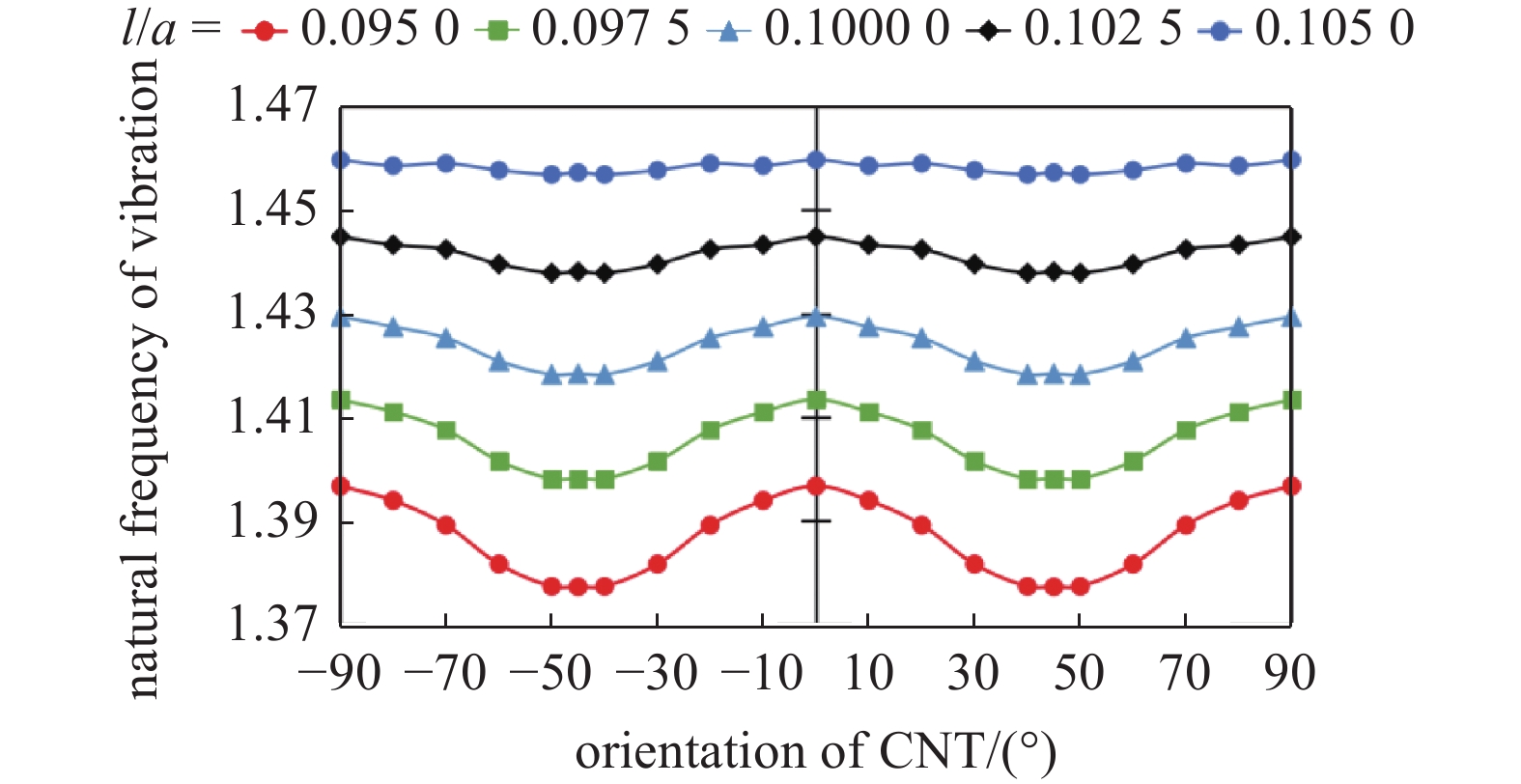

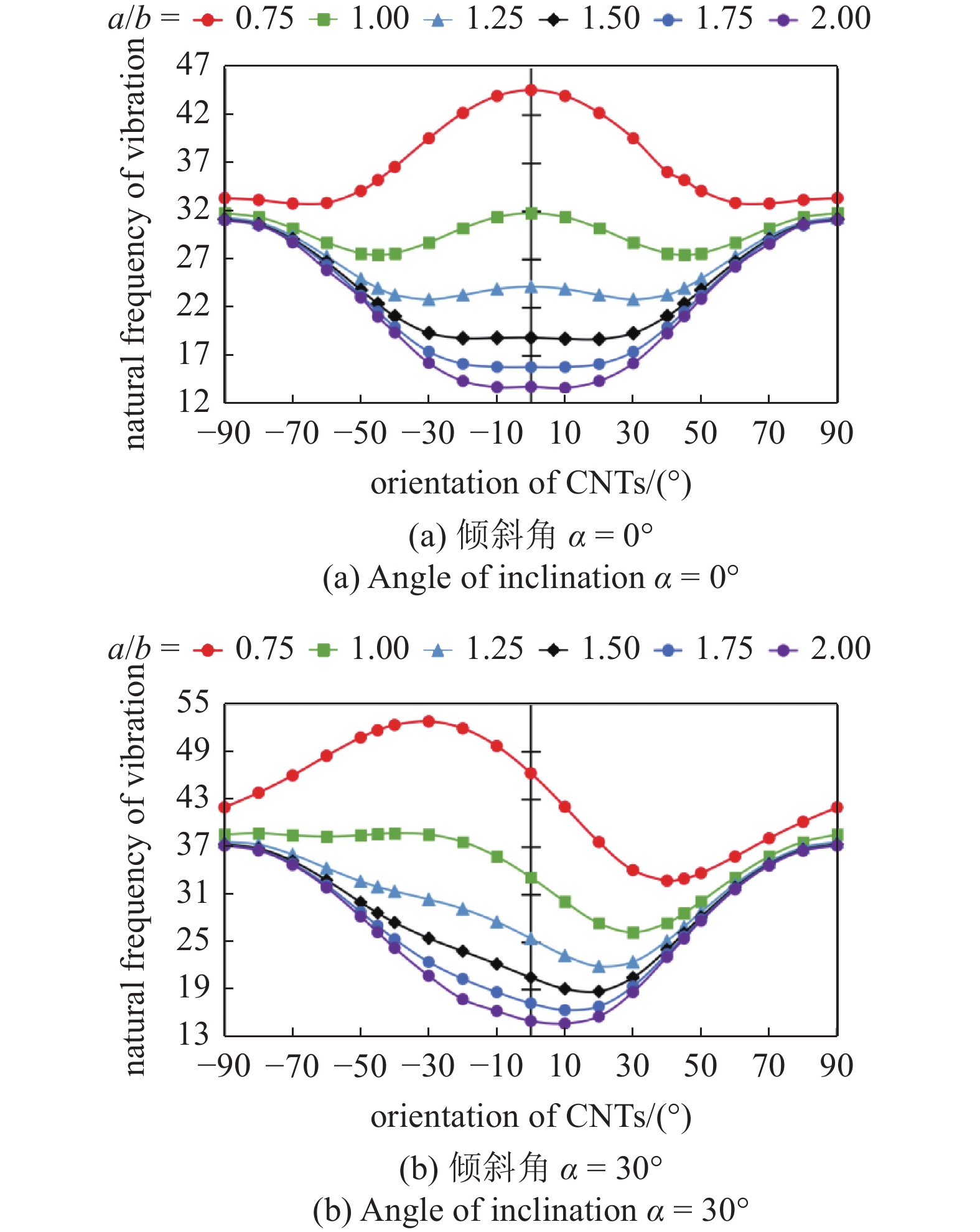

$ \varpi ({b^2}/l)\sqrt {{\rho ^{\text{m}}}/{E^{\text{m}}}} $ , 且与Zhu等[8]的数值结果进行了参考比较, 说明广义有限差分法这一算法的计算正确和有效性. 然后运用广义有限差分法数值分析了不同转向的碳纳米管对FG-CNTRC板结构自振频率的影响. 图10展示了不同分布型和不同倾斜角度$ \alpha $ 下, FG-CNTRC板中碳纳米管的旋转角度$ \beta $ 对结构第一阶自振频率$ {\lambda _1} = {\varpi _1}({b^2}/l)\sqrt {{\rho ^{\text{m}}}/{E^{\text{m}}}} $ 的影响, 可以看出碳纳米管在横向布置$ \beta = {0^ \circ } $ 和纵向布置$ \beta = {90^ \circ } $ 时其结构具有相同的自振效果, 在$ \beta = {45^ \circ } $ 斜向配置时其结构抗弯刚度最小, 自振频率最小; 随着倾斜角$ \alpha $ 的增大, 随同碳纳米管旋转的FG-CNTRC板数值结果不再呈周期性变化; 在$ \alpha = {30^ \circ } $ 时板最小自振发生在碳纳米管$ \beta = {30^ \circ } $ 左右; 随着倾斜角$ \alpha $ 的继续增大, 使FG-CNTRC板产生最小自振频率的碳纳米管转向角度从$ \beta = {45^ \circ } $ 逐渐减小.表 5 四周固支FG-CNTRC板的前6阶自振频率Table 5. Six natural frequencies of FG-CNTRC plate with all clamped boundaries图11展示了UD分布型和不同转向角度

$ \beta $ 下厚跨比$ l/a $ 对FG-CNTRC板第一阶自振频率$ {\varpi _1}{b^2}\sqrt {{\rho ^{\text{m}}}/{E^{\text{m}}}} $ 的影响, 可以看出FG-CNTRC板厚跨比与自振频率成正相关, 厚度增加的剪切效应使碳纳米管转向对自振频率的影响逐渐降低. 图12讨论了结构不同长宽比$ a/b $ 所构成的FG-CNTRC板对自振频率的影响, 发现当$ a/b \geqslant 1 $ 碳纳米管在$ \beta = - {90^ \circ },{90^ \circ } $ 时, 即竖向放置, 自振频率大小近乎相等; 在横向放置$ \beta = {0^ \circ } $ 时, 其随不同的长宽比$ a/b $ 配置产生不一样的自振效果, 且碳纳米管的放置角度对自振频率产生显著影响.4. 结论

本文采用广义有限差分法求解了基于一阶剪切变形理论的功能梯度碳纳米管增强复合材料(FG-CNTRC)板的静态线性弯曲和自振模态问题. 通过基准算例验证了该算法的精确性和高效性, 是一种基于移动最小二乘发展而来的简单高效的区域型无网格方法, 且能够快速方便地克服一阶剪切变形理论在薄板应用中的剪切自锁现象. 接着, 在此基础上进一步研究具有转向的碳纳米管、板宽厚比、倾斜角度等材料结构参数对FG-CNTRC板弯曲和自振模态的影响. 研究发现:

(1) 碳纳米管排布形式对结构刚度的影响差异性大, FG-CNTRC材料所形成的结构刚度大小依次有FG-O<FG-V<UD<FG-X型;

(2) 随着板倾斜角的增大, 同碳纳米管旋转的FG-CNTRC板自振频率不再呈周期性变化;

(3) 碳纳米管

$ \beta = - {90^ \circ },{90^ \circ } $ 时, 即竖向放置, 结构长宽比的改变近乎不影响结构刚度; 在横向放置$ \beta = $ $ {0^ \circ } $ 时, 随不同的长宽比变化产生不一样的结构刚度;(4) 在X和Y方向上存在着各向异性的刚度变化, 且碳纳米管的转向角度对结构产生显著影响. 最后需要指出的是, 本文主要侧重于验证广义有限差分法在计算FG-CNTRC板结构力学特性的有效性, 后续将基于广义有限差分法考虑更为复杂的数值计算模型.

-

表 1 相对误差

Table 1 Relative error

Thickness ratio $ l/a $ Relative error/% Uniform nodes Scattered nodes 0.10 0.022 0.070 0.15 0.014 0.044 0.20 0.046 0.061 0.25 0.018 0.018 0.30 0.010 0.016 0.35 0.015 0.030 表 2 材料属性

Table 2 Material properties

Equivalent parameters of reinforced-CNTs Matrix materials $ \begin{gathered} E_{11}^{{\text{CNT}}} = 5.6466{\text{ TPa}} \end{gathered} $ $ \begin{gathered} {E^{\text{m}}} = 2.1{\text{ GPa}} \end{gathered} $ $ \begin{gathered} E_{22}^{{\text{CNT}}} = 7.0800{\text{ TPa}} \end{gathered} $ $ \begin{gathered} {\rho ^{\text{m}}} = 1150{\text{ kg/}}{{\text{m}}^{\text{3}}} \end{gathered} $ $ \begin{gathered} G_{12}^{{\text{CNT}}} = 1.9447{\text{ TPa}} \end{gathered} $ $ \begin{gathered} {\mu ^{\text{m}}} = 0.34 \end{gathered} $ $ \begin{gathered} {\rho ^{{\text{CNT}}}} = 1400{\text{ kg/}}{{\text{m}}^{\text{3}}} \end{gathered} $ $ \begin{gathered} {G^{\text{m}}} = {E^{\text{m}}}/\left[ {2(1 + {\mu ^{\text{m}}})} \right] \end{gathered} $ $ \begin{gathered} \mu _{12}^{{\text{CNT}}} = 0.175\end{gathered} $ 表 3 碳纳米管的效能参数

Table 3 Efficiency parameters of CNTs

$ V_{{\text{CNT}}}^{\text{*}} $ $ {\eta _1} $ $ {\eta _2} $ $ {\eta _3} $ 0.11 0.149 0.934 0.934 0.14 0.150 0.941 0.941 0.17 0.149 1.381 1.381 表 4 四周固支FG-CNTRC板的中心弯曲

$ w/l $ Table 4 The center bending

$ w/l $ of FG-CNTRC plate with all clamped boundaries$ a/l $ Distributions FEM[8] GFDM 10 UD 2.227 × 10−3 2.222 × 10−3 FG-V 2.351 × 10−3 2.349 × 10−3 FG-O 2.506 × 10−3 2.505 × 10−3 FG-X 2.104 × 10−3 2.103 × 10−3 20 UD 1.338 × 10−2 1.337 × 10−2 FG-V 1.591 × 10−2 1.591 × 10−2 FG-O 1.856 × 10−2 1.858 × 10−2 FG-X 1.150 × 10−2 1.149 × 10−2 50 UD 0.2618 0.2626 FG-V 0.3653 0.3657 FG-O 0.4719 0.4721 FG-X 0.1900 0.1906 表 5 四周固支FG-CNTRC板的前6阶自振频率

Table 5 Six natural frequencies of FG-CNTRC plate with all clamped boundaries

-

[1] 李渊, 邓子辰, 叶学华等. 基于辛理论的载流碳纳米管能带分析. 力学学报, 2016, 48(1): 135-139 (Li Yuan, Deng Zichen, Ye Xuehua, et al. Analysing the wave scattering in single-walled carbon nanotube conveying fluid based on the symplectic theory. Chinese Journal of Theoretical and Applied Mechanics, 2016, 48(1): 135-139 (in Chinese) [2] 张田忠, 郭兴明. 径向压缩单壁碳纳米管的力学行为. 力学学报, 2005, 37(4): 408-412 (Zhang Tianzhong, Guo Xingming. Mechanical behavior of radial compressed single-walled carbon nanotubes. Chinese Journal of Theoretical and Applied Mechanics, 2005, 37(4): 408-412 (in Chinese) [3] 沈惠申. 功能梯度碳纳米管增强复合材料结构建模与分析研究进展. 力学进展, 2016, 46: 478-505 (Shen Huishen. Modeling and analysis of functionally graded carbon nanotube reinforced composite structures: A review. Advances in Mechanics, 2016, 46: 478-505 (in Chinese) [4] Shen HS. Nonlinear bending of functionally graded carbon nanotube-reinforced composite plates in thermal environments. Composite Structures, 2009, 91(1): 9-19 doi: 10.1016/j.compstruct.2009.04.026

[5] 李海军, 郭万林. 单壁碳纳米管的等效梁单元有限元模型. 力学学报, 2006, 38(4): 488-495 (Li Haijun, Guo Wanlin. Finite element model with equivalent beam elements of single-walled carbon nanotubes. Chinese Journal of Theoretical and Applied Mechanics, 2006, 38(4): 488-495 (in Chinese) [6] 李琳, 徐亚兰. 随机FG-CNTRC结构的动力特性分析. 西安电子科技大学学报, 2019, 46(6): 140-146 (Li Lin, Xu Yalan. Analysis of dynamic characteristics of random FG-CNTRC structures. Journal of Xidian University, 2019, 46(6): 140-146 (in Chinese) [7] Quoc TH, Tham VV, Tu TM. Active vibration control of a piezoelectric functionally graded carbon nanotube-reinforced spherical shell panel. Acta Mechanica, 2021, 232(3): 1005-1023

[8] Zhu P, Lei ZX, Liew KM. Static and free vibration analyses of carbon nanotube-reinforced composite plates using finite element method with first order shear deformation plate theory. Composite Structures, 2012, 94(4): 1450-1460 doi: 10.1016/j.compstruct.2011.11.010

[9] Lei J, Zhang CZ, Bui TQ. Transient dynamic interface crack analysis in magnetoelectroelastic bi-materials by a time-domain BEM. European Journal of Mechanics A-Solids, 2015, 49: 146-157

[10] 宋康祖, 陆明万, 张雄. 固体力学中的无网格方法. 力学进展, 2000, 30(1): 55-65 (Song Kangzu, Lu Mingwan, Zhang Xiong. Meshless method for solid mechanics. Advances in Mechanics, 2000, 30(1): 55-65 (in Chinese) [11] 张雄, 胡炜, 潘小飞等. 加权最小二乘无网格法. 力学学报, 2003, 35(4): 425-431 (Zhang Xiong, Hu Wei, Pan Xiaofei, et al. Meshless weighted least-square method. Chinese Journal of Theoretical and Applied Mechanics, 2003, 35(4): 425-431 (in Chinese) [12] Lei ZX, Liew KM, Yu JL. Large deflection analysis of functionally graded carbon nanotube-reinforced composite plates by the element-free kp-Ritz method. Computer Methods in Applied Mechanics & Engineering, 2013, 256(2): 189-199

[13] Do VNV, Lee CH. Bending analyses of FG-CNTRC plates using the modified mesh-free radial point interpolation method based on the higher-order shear deformation theory. Composite Structures, 2017, 168: 485-497 doi: 10.1016/j.compstruct.2017.02.055

[14] Gavete L, Gavete ML, Benito JJ. Improvements of generalized finite difference method and comparison with other meshless method. Applied Mathematical Modelling, 2003, 27(10): 831-847 doi: 10.1016/S0307-904X(03)00091-X

[15] 陈增涛, 王发杰, 王超. 广义有限差分法在含阻抗边界空腔声学分析中的应用. 力学学报, 2021, 53(4): 1183-1195 (Chen Zengtao, Wang Fajie, Wang Chao. Application of generalized finite difference method in acoustic analysis of cavity with impedance boundary. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(4): 1183-1195 (in Chinese) [16] Benito JJ, Urena F, Gavete L. Influence of several factors in the generalized finite difference method. Applied Mathematical Modelling, 2001, 25(12): 1039-1053 doi: 10.1016/S0307-904X(01)00029-4

[17] Urena F, Salete E, Benito JJ, et al. Solving third- and fourth-order partial differential equations using GFDM: application to solve problems of plates. International Journal of Computer Mathematics, 2012, 89(3): 366-376 doi: 10.1080/00207160.2011.587871

[18] Fan CM, Huang YK, Li PW, et al. Application of the generalized finite difference method to inverse biharmonic boundary-value problems. Numerical Heat Transfer Part B Fundamentals, 2014, 65(2): 129-154 doi: 10.1080/10407790.2013.849979

[19] Gu Y, Lei J, Fan CM, et al. The generalized finite difference method for an inverse time-dependent source problem associated with three-dimensional heat equation. Engineering Analysis with Boundary Elements, 2018, 91: 73-81 doi: 10.1016/j.enganabound.2018.03.013

[20] Qu WZ, Gu Y, Zhang YM, et al. A combined scheme of generalized finite difference method and Krylov deferred correction technique for highly accurate solution of transient heat conduction problems. International Journal for Numerical Methods in Engineering, 2019, 117(1): 63-83 doi: 10.1002/nme.5948

[21] 李艾伦, 傅卓佳, 李柏纬等. 含肿瘤皮肤组织传热分析的广义有限差分法. 力学学报, 2018, 50(5): 1198-1205 (Li Ailun, Fu Zhuojia, Li Powei, et al. Generalized finite difference method for bioheat transfer analysis on skin tissue with tumors. Chinese Journal of Theoretical and Applied Mechanics, 2018, 50(5): 1198-1205 (in Chinese) [22] 汤卓超, 傅卓佳, 范佳铭. 广义有限差分法求解Kirchhoff和Winkler薄板弯曲问题. 固体力学学报, 2018, 39(4): 419-428 (Tang Zhuochao, Fu Zhuojia, Fan Chiaming. Generalized finite difference method for solving Kirchhoff plate and Winkler plate bending problems. Chinese Journal of Solid Mechanics, 2018, 39(4): 419-428 (in Chinese) [23] Xi Q, Fu ZJ, Li YD, et al. A hybrid GFDM-SBM solver for acoustic radiation and propagation of thin plate structure under shallow sea environment. Journal of Theoretical and Computational Acoustics, 2020, 28(2): 2050008 doi: 10.1142/S2591728520500085

[24] Li YD, Tang ZC, Fu ZJ. Generalized finite difference method for plate bending analysis of functionally graded materials. Mathematics, 2020, 8(11): 1940 doi: 10.3390/math8111940

[25] 李煜冬, 傅卓佳, 汤卓超. 一种局部无网格配点法在功能梯度材料板上的应用. 计算机辅助工程, 2021, 30(1): 1-7 (Li Yudong, Fu Zhuojia, Tang Zhuochao. Application of a local meshless point collocation method to functionally graded material plate. Computer Aided Engineering, 2021, 30(1): 1-7 (in Chinese) [26] Mora-Didastjerdi R, Pourasghar A, Foroutan M, et al. Vibration analysis of functionally graded nanocomposite cylinders reinforced by wavy carbon nanotube based on mesh-free method. Journal of Composite Materials, 2013, 48(15): 1901-1913

[27] Memar AM, Zhang LW, Liew KM. Isogeometric analysis of the effect of CNT orientation on the static and vibration behaviors of CNT-reinforced skew composite plates. Computer Methods in Applied Mechanics and Engineering, 2017, 317: 341-379 doi: 10.1016/j.cma.2016.12.009

[28] 龙志飞, 岑松. 有限元法新论−原理, 程序, 进展. 北京: 中国水利水电出版社, 2001 Long Zhifei, Cen Song. New Concept of Finite Element Method—Principle, Programme, Progress. Beijing: China Water-Power Press, 2001 (in Chinese)

[29] Li Q, Soric J, Jarak T, et al. A locking-free meshless local Petrov-Galerkin formulation for thick and thin plates. Journal of Computational Physics, 2005, 208(1): 116-133 doi: 10.1016/j.jcp.2005.02.008

[30] Fu ZJ, Xi Q, Li YD, et al. Hybrid FEM-SBM solver for structural vibration induced underwater acoustic radiation in shallow marine environment. Computer Methods in Applied Mechanics & Engineering, 2020, 369: 113236

下载:

下载: