我国页岩气资源量巨大,其中地质资源量达134× 1012m3 (约是常规天然气地质资源量的2倍),可采资源量达25×1012m3[1],具有广阔的勘探开发前景[2, 3, 4].页岩气资源成功开采需要一系列关键技术,包括页岩气藏``甜点''预测、水平井钻井、体积压裂等,而页岩的脆性评价又是这些关键技术中至关重要的组成部分[5, 6, 7].

针对岩石的脆性问题,国内外学者开展了大量研究工作. 研究结果表明,影响岩石脆性的因素较多,包括矿物组份、地应力环境、非均质性(层理方向、裂缝发育、微观缺陷等)、岩石力学参数等[8, 9, 10, 11, 12]. 基于这些影响因素提出了多种脆性指数计算方法,概括起来可以分成以下几大类:(1)基于脆性矿物含量的脆性指数计算方法[13, 14, 15];(2)基于岩石应力-应变曲线的脆性指数计算方法[8, 16, 17, 18];(3)基于岩石强度参数的脆性指数计算方法[19, 20];(4)其他脆性指数计算方法[21, 22]. 其中,基于岩石矿物组份和应力-应变曲线的脆性指数计算方法应用最为广泛.

从研究方法来看,前人研究多将脆性作为岩石的一种固有属性来讨论,即认为脆性由岩石自身组构决定,而针对外界条件变化(尤其是流体侵入)对页岩脆性的影响研究较少. 事实上,在钻井和后期改造过程中,页岩储层一直伴随着应力和温度改变、工作液侵入等外界条件的变化,而这些外界因素与井壁垮塌及缝网形成关系十分密切. 研究认为,随有效应力增大岩石脆性呈减弱趋势[23, 24],对于孔隙度越高和强度越低的岩石,其脆性减弱越快[8, 25]. 其次,温度变化也会影响岩石脆性. 温度升高会导致页岩无机矿物软化及有机质分解和塑性流动,进而使得岩石脆性减弱[8, 26, 27, 28]. 而工作液侵入对岩石破坏机制影响更加复杂. 工作液(包括钻井完井液和压裂液)中一般含有一定浓度的K+,K+能与页岩中的黏土矿物发生离子交换,而这种离子交换作用能诱发页岩中的黏土矿物分散(如高岭石)[29]和增强岩石骨架收缩性[8, 30],进而导致页岩脆性减弱. 也有学者认为,钻井完井液侵入还会引发其他一系列的负面作用,如增加孔隙压力[31, 32, 33]、产生界面张力[31, 32]、润湿性改变[34, 35]、水化膨胀[36]、碱液侵蚀[37, 38]等,并详细讨论了这些负面作用对岩石结构破坏及强度弱化的影响机制,但未对有关岩石脆性变化的问题进行讨论.

综上所述,目前关于页岩脆性影响机制研究多集中在岩石自身组构方面,而对钻井完井过程中工作液浸泡对页岩脆性的影响机制研究还未见文献报道. 本文首先对脆性评价方法及模型进行了优选和阐述,其次,分别开展水基钻井完井液和油基钻井完井液浸泡后页岩的三轴力学实验,并利用优选的模型进行浸泡前后页岩脆性评价. 最后,结合毛管自吸、微观扫描、水化膨胀、摩擦系数测试等实验对浸泡前后页岩的脆性变化机制进行了论述.

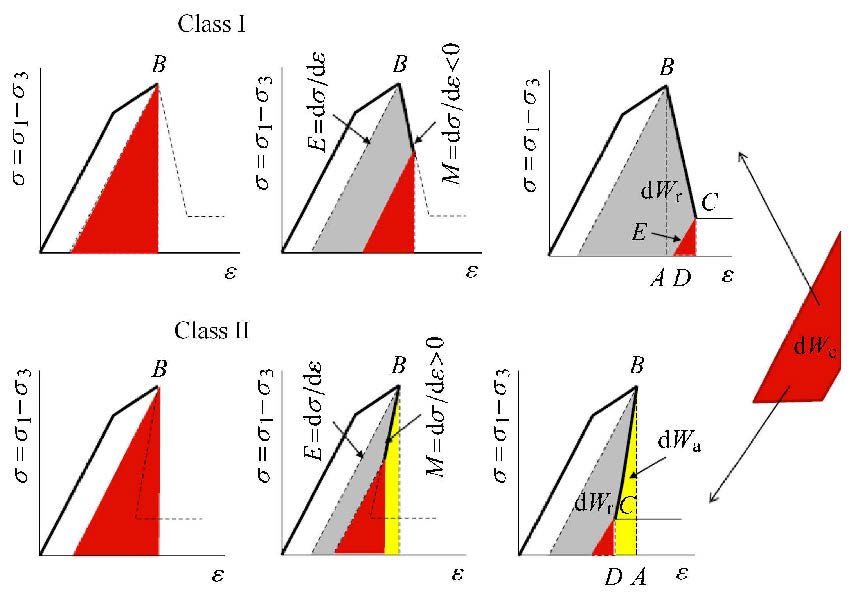

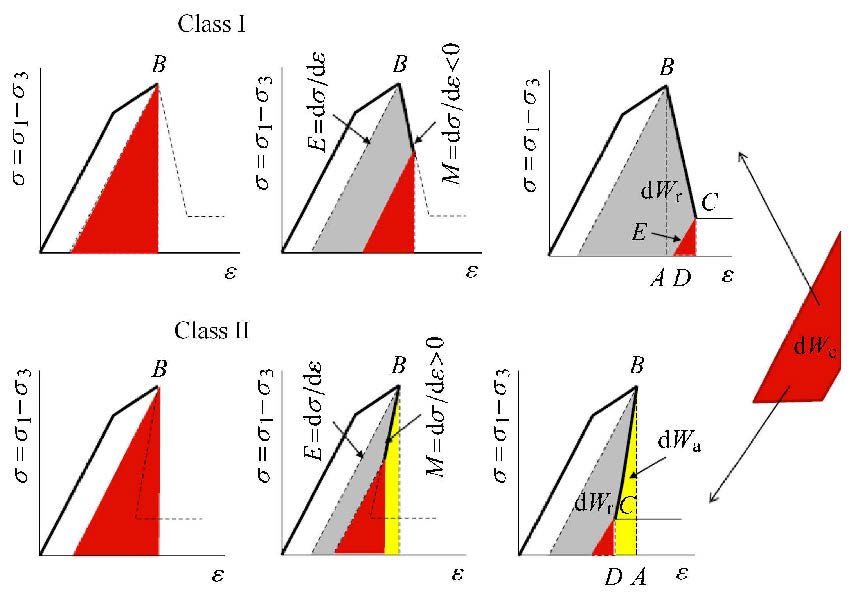

1 页岩脆性指数计算模型实践表明,相比其他脆性评价方法而言,基于岩石破坏过程中的应力-应变曲线的脆性评价方法能较为全面反映岩石自身组构(包括矿物组份、结构、流体等)以及环境变化(如温度、应力、流体侵入等)对脆性的影响,其脆性评价结果也与工程实际更为接近.本文选用Tarasov和Potvin [17]提出脆性指数Bindex计算模型,如式(1)∼式(4)所示.该模型基于应力-应变曲线变化特征及能量守恒原理,充分考虑了破坏前和破坏后的能量变化(图1). 经推导,Bindex最终可以表示成岩石破坏过程中的断裂能 dWr与破坏前累积的弹性能dWe的比值. Bindex越大表明岩石脆性越弱.$${B_{{\text{index}}}} = {\text{d}}{W_{\text{r}}}/d{W_{\text{e}}} = \left( {M - E} \right)/M(1)$$ $${\text{d}}{W_{\text{e}}} = (\sigma _B^2 - \sigma _C^2)/(2E){\text{ }}(2)$$ $${\text{d}}{W_{\text{a}}} = (\sigma _B^2 - \sigma _C^2)/(2M){\text{ }}(3)$$ $${\text{d}}{W_{\text{r}}} = {\text{d}}{W_{\text{e}}} - {\text{d}}{W_{\text{a}}} = [(\sigma _B^2 - \sigma _C^2)(M - E)]/(2EM){\text{ }}(4)$$ 式中,dWr为峰后断裂能,J;dWe为峰后破坏过程B和C点间消耗的弹性能,J;dWa为破坏过程额外吸收的能量(I型)或者释放的能量(II型),J;M为峰后模量,M=dσ/d,对于I型,M取负值,对于II型,M取正值,MPa;E为弹性模量,MPa; σB和σC分别为B,C两点的差应力值,MPa.

|

图1 岩石破坏能量转化原理图 Fig.1 Energy transformation schematic diagram of rock failure[17] |

实验用样品来自鄂尔多斯盆地延长组井下页岩和四川盆地龙马溪组天然露头页岩. 延长组页岩矿物组份:石英(32.5%)、斜长石(3.4%)、菱铁矿(3.9%)、黄铁矿(2.4%)、伊利石(37.7%)、伊/蒙间层(5.4%)、高岭石(9.7%)、绿泥石(5.0%). 有机碳含量(TOC)为6.1%. 龙马溪组页岩矿物组份:石英(45.9%)、白云石(1.4%)、斜长石(7.2%)、方解石(3.5%)、黄铁矿(2.7%)、伊利石(33.4%)、伊/蒙间层(0.9%)、高岭石(4.0%)、绿泥石(1.0%). 有机碳含量为3.3%. 实验岩心柱塞均沿着平行于层理面方向钻取.

实验用钻井完井液包括水基钻井完井液、油基钻井完井液两类. 其中,水基钻井完井液配方为:清水+2%∼4%膨 润土+0.5%∼1%降滤失剂+0.5%∼1%增黏+2%∼3%防塌剂+2%∼3%润滑剂等,pH=9.油基钻井完井液配方为:70%∼80%白油+氧化沥青+有机膨润土+乳化剂+润湿剂+降滤失剂+防塌封堵剂+生石灰粉等,pH=11.5.

2.2 实验方法选用基础物性和动态杨氏模量接近,且肉眼观察无裂缝的岩心用于实验. 将选好的岩心分别浸泡在水基钻井完井液和油基钻井完井液中,浸泡24h后测试其力学参数变化,并和干岩样力学参数进行对比.其中,浸泡时间主要依据页岩自吸量、膨胀率稳定时间而确定(见讨论部分).实验仪器采用美国GCTS公司的RTR-1000型三轴岩石力学测试系统. 实验在围压40,MPa及室温(25C)条件下进行.

3 实验结果 3.1 水基钻井完井液浸泡前后页岩脆性变化特征如表1所示,和干岩样相比,水基钻井完井液浸泡后的岩样泊松比主要表现为增大,杨氏模量主要表现为减小,抗压强度均表现为降低. 经计算,干岩样的Bindex为1.221.29,平均1.26,浸泡后的岩样Bindex为1.431.52,平均1.48. 浸泡后的岩样Bindex增大了15.5%;20.6%,平均17.8%. 根据前述脆性指数计算模型可知,Bindex增大意味着岩石出现由脆性向塑性过渡的趋势,即脆性程度减弱.

| 表1 水基钻井完井液浸泡前后延长组页岩力学参数 Table 1 Mechanical parameters of Yanchang shales before and after soaked in water-based drilling {} completion fluid |

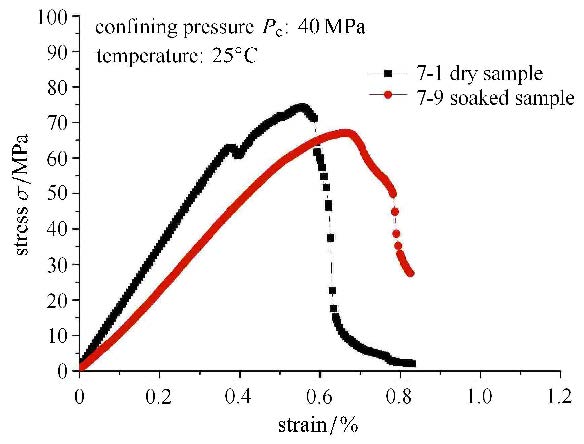

如图2所示,水基钻井完井液浸泡后的岩样峰后曲线斜率绝对值减小,表现出由脆性向塑性转变的趋势,但仍然呈现出脆破坏特征.当轴向应力加载至峰值强度后,岩心的轴向承载能力迅速降低,甚至完全丧失承载能力,此阶段变形量很小,岩心迅速破裂形成宏观断裂面,发生脆性破坏.

|

图2 水基钻井完井液浸泡前后应力-应变曲线 Fig.2 Stress vs. strain cureve of cores before and after soaked in water-based drilling completion fluid |

如表2所示,龙马溪组页岩杨氏模量和抗压强度均较延长组页岩大,水基钻井液浸泡后二者均出现了减弱趋势. 干岩样的Bindex为1.82∼2.01,平均1.92. 浸泡后的岩样Bindex为2.75∼2.93,平均2.84.浸泡后的岩样Bindex增大了45.8%∼51.1%,平均48.5%.实验数据表明,龙马溪组页岩脆性较延长组页岩弱,其次,水基钻井完井液浸泡也会导致龙马溪 组页岩脆性降低,且降低幅度较延长组页岩大.

| 表2 水基钻井完井液浸泡前后页龙马溪组岩力学参数 Table 2 Mechanical parameters of Longmaxi shales before and after soaked in water-based drilling completion fluid |

如表3所示,和干岩样相比,油基钻井完井液浸泡后的岩样泊松比、杨氏模量、抗压强度均表现为降低. 经计算,干岩样的Bindex为1.55∼2.05,平均1.80,浸泡后的岩样Bindex为2.10∼2.48,平均2.29. 浸泡后的岩样Bindex增大了21.0%∼35.5%,平均28.3%,实验数据表明,油基钻井完井液浸泡后的延长组页岩也出现了脆性程度减弱趋势,且脆性减弱幅度较水基钻经计算,干岩样的Bindex为1.552.05,平均1.80,浸泡后的岩样Bindex为2.102.48,平均2.29. 浸泡后的岩样Bindex增大了21.0%∼35.5%,平均28.3%,实验数据表明,油基钻井完井液浸泡后的延长组页岩也出现了脆性程度减弱趋势,且脆性减弱幅度较水基钻井完井液浸泡后的延长组页岩大.

| 表3 油基钻井完井液浸泡前后页延长组岩力学参数 Table 3 Mechanical parameters of Yanchang shales before and after soaked in oil-based drilling completion fluid |

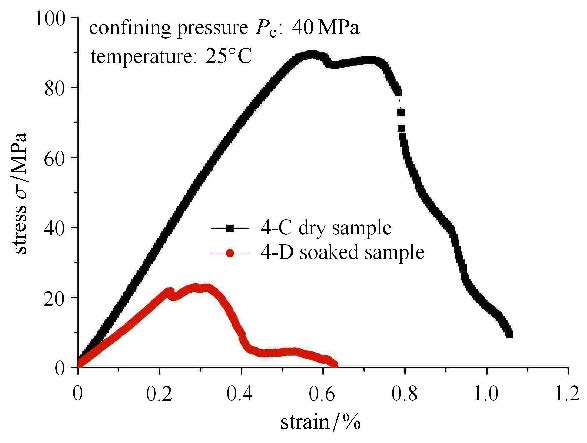

如图3所示,浸泡后页岩峰值强度前应力-应变曲线斜率和峰值强度明显降低,峰值强度后,曲线斜率绝对值减小,应力 跌落速度减慢,表现出由脆性向塑性过渡的趋势.

|

图3 油基钻井完井液浸泡前后应力-应变曲线 Fig.3 Stress vs. strain cureve of cores before and after soaked inoil-based drilling completion fluid |

如表4所示,和干岩样相比,油基钻井完井液浸泡后的龙马溪组页岩杨氏模量、抗压强度同样表现为减小趋势. 另外,干岩样的Bindex为1.70∼1.80,平均1.78,浸泡后的岩样Bindex为2.71∼2.93,平均2.82. 浸泡后的岩样Bindex增大了54.9%∼62.8%,平均58.9%,实验数据表明,油基钻井完井液浸泡后的龙马溪组页岩也出现脆性程度减弱的趋势,且脆性减弱幅度大于水基钻井完井液浸泡的龙马溪组页岩.

| 表4 油基钻井完井液浸泡前后页龙马溪组岩力学参数 Table 4 Mechanical parameters of Longmaxi shales before and after soaked in oil-based drilling completion fluid |

由实验数据可以得出,延长组页岩脆性强于龙马溪组;水基钻井完井液和油基钻井完井液浸泡均能导致页岩脆性减弱,且油基钻井完井液浸泡降低页岩脆性幅度大于水基钻井完井液;和延长组页岩相比,相同工作液浸泡条件下,龙马溪组页岩脆性降低幅度更大.

4 讨 论影响页岩脆性原因较多. 本文通过考虑页岩自身矿物组成、结构、以及与工作液接触所产生的物理化学反应等因素,系统分析了工作液浸泡过程中页岩脆性变化机制,主要包括以下几个方面.

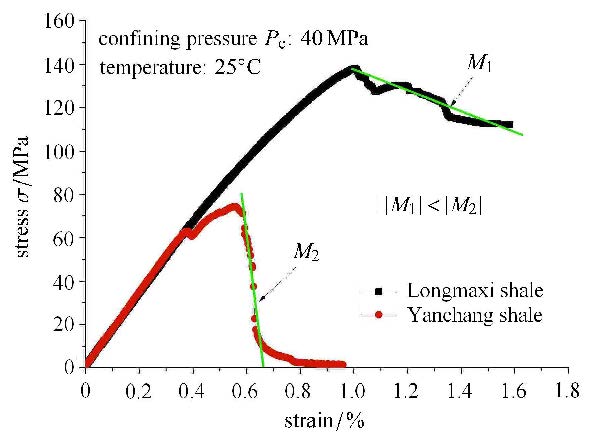

4.1 层理面胶结强度对脆性的影响由表1;表4数据可知,干燥条件下延长组页岩脆性指数Bindex均较龙马溪组页岩的小,表明延长组页岩脆性强于龙马溪组页岩. 由式(1)可知,脆性指数Bindex取决于岩石弹性模量E和应力-应变曲线峰后段斜率M的绝对值大小,若E越大,M越小,则脆性指数Bindex越大. 实验数据表明,龙马溪组页岩杨氏模量均大于延长组页岩,其次,由图4可知,龙马溪组页岩破坏后应力跌落较为缓慢,而延长组页岩破坏后应力跌落较快,导致前者应力-应变曲线峰后段斜率M的绝对值明显比后者小,因此,龙马溪组页岩脆性指数Bindex较延长组页岩的大.

|

图4 两种页岩典型应力-应变曲线 Fig.4 Typical stress-strain curves of Yanchang shale and Longmaxi shale |

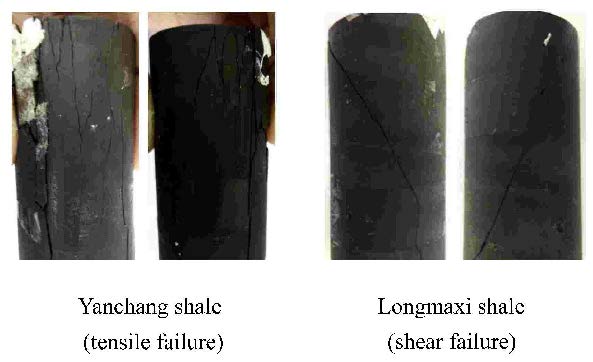

导致上述差别的原因主要在于两种页岩在层理面胶结强度方面存在较大差异.层理面胶结强度越大,层理越不容易开裂,岩石越容易发生剪切破坏,相反,若层理面胶结强度越低,则层理越容易开裂,岩石越容易沿着层理面发生拉伸破坏[39, 40].如图5所示,从两种页岩破坏特征来看,由于延长组页岩层理面胶结强度较低,破坏面主要沿着层理面方向发展,形成张性裂缝;而龙马溪组页岩层理面胶结强度较高,破坏面与层理面呈一定夹角发育,形成剪切裂缝.由此可以推断,延长组页岩破坏以拉伸破坏为主,而龙马溪组页岩以剪切破坏为主.拉伸破坏过程中岩石的塑性变形程度较低,且峰后段破坏面摩擦阻力较小,峰后应力迅速跌落,表现为脆性增强,而剪切破坏过程中岩石塑性变形程度较大,且破坏过程中剪切面错动会产生较大的摩擦阻力,导致峰后应力跌落缓慢,表现为脆性减弱[41].

|

图5 两种页岩典型破坏特征 Fig.5 Typical damage characteristics of Yanchang shale andvskip -1mm Longmaxi shale |

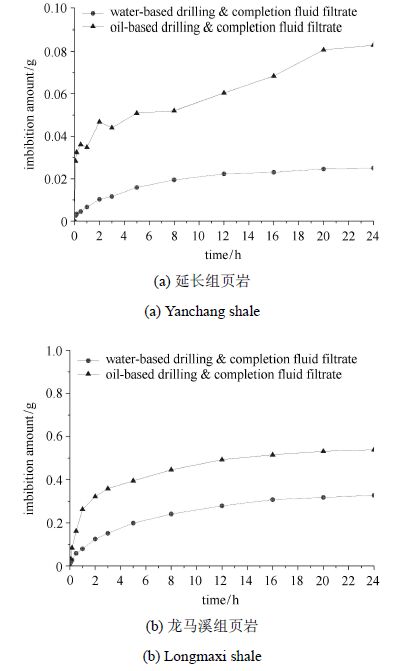

润湿性测试结果表明,白油对延长组页岩和龙马溪组页岩的接触角均为0°,水对延长组页岩的润湿接触角为57.4°∼64.6°,对龙马溪组页岩的润湿接触角为28°∼32°. 由此可知,两种页岩既亲水 又亲油,即混合润湿,这为页岩毛管自吸创造了有利条件.如图6所示,毛管自吸实验结果表明,水基钻井完井液滤液自吸量随时间延长 呈缓慢增大趋势,12h后基本达到平衡,24h后延长组页岩自吸量达到0.025g,龙马溪组页岩自吸量达到0.328g.对油基钻井完井液滤液而言,由于页岩具有强油湿性,在自吸开始阶段(小于5min),自吸量随时间增长而快速增大,随后呈缓慢增大趋势,直到20h后才趋于平衡,24h后延长组页岩自吸量达到0.083g,龙马溪组页岩自吸量达到0.539g.综上所述,油基钻井完井液滤液 自吸量大于水基钻井完井液滤液,其次,相同工作液条件下,龙马溪组页岩自吸能力强于延长组页岩.

|

图6 页岩自吸量随时间变化曲线 Fig.6 Variation curve of shale imbibition amount vs. time |

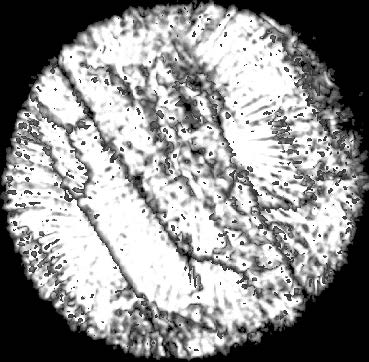

将自吸后的页岩进行超声波扫描发现(图7),页岩内部产生了大量层理缝,且部分层理缝相互贯通,缝宽分布范 围为70;240micro;m.自吸增大了孔隙和层理面孔隙压力,导致层理缝尖端应力强度因子增大,自吸量越大,层理缝越容易扩展,其次,润湿性流体侵入层理面后,将在层理面间产生毛管力,导致层理缝尖端应力强度因子增加及临界断裂韧度降低,润湿性越强层理缝越容易扩展[31, 32, 34, 35].

|

图7 自吸后延长组页岩内部层理缝扩展超声波扫描图像 Fig.7 Ultrasonic scanning image of expanded bedding fractures inner shales after imbibition |

不难看出,由于油基钻井完井液比水基钻井完井液具有更大的自吸量和更强的润湿性,油基钻井完井液浸泡后的页岩微结构破坏会更加严重. 层理缝的产生将导致页岩结构疏松,破坏前变形量增大,宏观表现为岩石脆性减弱,产生的层理缝越多,脆性减弱幅度越大,因此,油基钻井完井液浸泡后的页岩脆性减弱程度大于水基钻井液浸泡后的页岩. 其次,由于龙马溪组页岩对两种工作液的自吸能力均强于延长组页岩,因此,和延长组页岩相比,龙马溪组页岩由自吸导致的裂缝扩展将更加明显,这也是龙马溪组页岩浸泡后脆性减弱幅度大于龙马溪组页岩的原因之一.

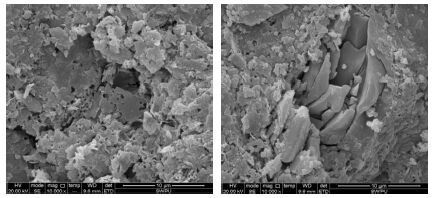

4.3 碱液侵蚀降低页岩脆性页岩富含石英、长石、黏土矿物等硅质矿物,高pH值钻井完井液接触页岩时会产生碱液侵蚀作用. 如图8所示,碱液侵蚀作用会改变页岩微结构特征,使得与钻井完井液接触的页岩表面产生大量溶蚀孔隙,并导致矿物颗粒碎裂,使得原本存在的微裂缝和层理等弱结构面发生破坏,碱性越强碱液侵蚀作用越明显[37, 38, 42].

|

图8 碱液浸泡后龙马溪组页岩表面扫描电镜图像 Fig.8 SEM images of shale surface after soaked in lye |

实验采用的油基钻井完井液pH值为11.5,而水基钻井完井液pH值为9.0,因此,油基钻井完井液碱液侵蚀作用将强于水基钻井完井液,其导致的页岩微结构破坏程度也更大,脆性减弱幅度也越大.另外,龙马溪组页岩对两种工作液的自吸量均大于延长组页岩,因此,浸泡过程中龙马溪组页岩内部参与反应的碱液就更多,由碱液侵蚀导致的页岩微结构破坏就更加严重.这也是导致龙马溪组页岩脆性减弱程度比延长组页岩更大的原因之一.

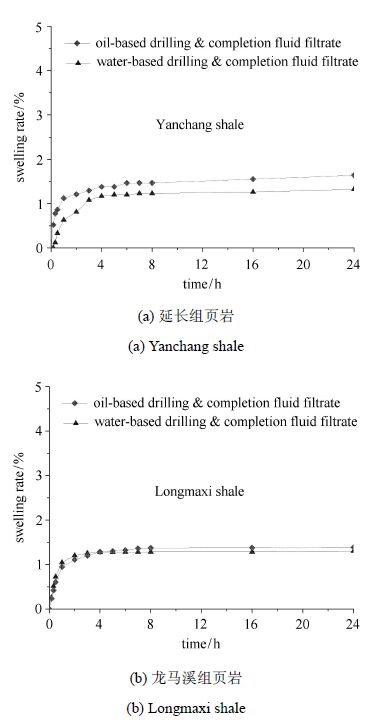

4.4 水化膨胀降低页岩脆性如图9所示,页岩膨胀性实验结果显示,延长组页岩在水基钻井完井液中的膨胀率为1.32%,而在油基钻井完井液中的膨胀率为1.64%(图9(a)). 龙马溪组页岩在水基钻井完井液中的膨胀率为1.30%,而在油基钻井完井液中的膨胀率为1.39% (图9(b)).页岩水化膨胀主要是由于页岩中的膨胀性黏土矿物(如蒙脱石、伊/蒙间层矿物)与外界流体发生物理化学作用所导致的.一般认为,油基钻井完井液含水量少,能有效的抑制页岩水化膨胀.但由于强碱性环境能促进页岩水化膨胀[43],因此,油基钻井完井液浸泡后的页岩膨胀性反而会比水基钻井完井液浸泡后的更强.虽然龙马溪组页岩具有较强的自吸能力,但相同工作液条件下,龙马溪组页岩膨胀性却略低于延长组页岩.由两种页岩矿物组份数据可知,延长组页岩伊/蒙间层矿物含量为5.4%,而龙马溪组页岩伊/蒙间层矿物含量仅为0.9%.延长组页岩膨胀性黏土矿物含量明显高于龙马溪组页岩,导致龙马溪组页岩膨胀性低于延长组页岩.

|

图9 页岩膨胀率随浸泡时间变化关系 Fig.9 Variation of shale swelling rate vs. soaking time |

根据前人研究成果可知,页岩水化膨胀过程中会产生膨胀应力,即使膨胀率很小也会导致岩石强度大幅度下[44]. 当膨胀应力超过岩石强度时,将会导致岩石发生破裂,宏观上表现为岩石强度弱化和塑性增强.膨胀率越大,页岩脆性减弱幅度越大.因此,膨胀性差异也是油基钻井完井液浸泡后的页岩脆性减弱程度大于水基钻井完井液浸泡后页岩的原因之一.

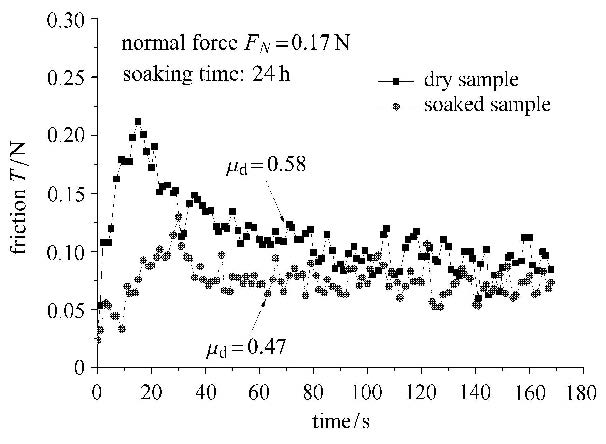

4.5 液相润滑降低页岩脆性由于页岩的混合润湿性,工作液侵入裂缝后,液相会迅速在裂缝表面铺展开,并在颗粒表面形成液膜. 液膜的存在会降低裂缝表面摩擦系数,且液膜润滑性越好,摩擦系数减小幅度越明显. 如图10图11所示,裂缝岩样(岩心沿层理面劈裂造缝)摩擦系数测试结果显示,水基钻井完井液滤液浸泡后的裂缝岩样裂缝面动摩擦系数µd由干样状态的0.58降低至0.47,降低幅度为19.0%;而油基钻井完井液滤液浸泡后的裂缝岩样裂缝面动摩擦系数µd由干样状态的0.76降低至0.48,降低幅度为36.8%.和延长组页岩相比,龙马溪组页岩裂缝面摩擦系数具有类似的变化特征,水基钻井液和油基钻井完井液均能导致裂缝面摩擦系数降低,且油基钻井完井液浸泡后裂缝面摩擦系数下降幅度较水基钻井完井液浸泡条件下的大[38].

|

图10 水基钻井完井液滤液浸泡前后延长组页岩裂缝面摩擦力随时间变化曲线 Fig.10 Variation curve of friction on fracture surface with time before and after soaked in water-based drilling and completion fluid |

|

图1 油基钻井完井液滤液浸泡前后延长组页岩裂缝面摩擦力测试曲线 Fig.11 Variation curve of friction on fracture surface with time before and after soaked in oil-based drilling and completion fluid |

综上所述,两种钻井完井液滤液均能导致页岩裂缝面动摩擦系数降低,且油基钻井完井液浸泡后动摩擦系数降低幅度更大.裂缝面摩擦系数越低,岩石脆性越弱[13].

5 结 论本文通过开展水基钻井完井液与油基钻井完井液浸泡后页岩三轴力学实验,并利用优选的脆性指数模型分析了页岩浸泡前后页岩脆性变化机制,并得到了如下主要结论:

(1)延长组页岩脆性强于龙马溪组页岩. 由于龙马溪组页岩层理面胶结强度较延长组页岩高,导致龙马溪组页岩以剪切破坏为主,破坏过程中塑性变形大,破坏面摩擦阻力大,脆性较弱;而延长组页岩以拉伸破坏为主,破坏过程中塑性变形小,破坏面摩擦阻力小,脆性较强.

(2)水基钻井完井液和油基钻井完井液浸泡均能导致页岩脆性减弱,且油基钻井完井液浸泡页岩脆性减弱幅度更大. 钻井完井液浸泡 会导致页岩毛管自吸、碱液侵蚀、水化膨胀、裂缝面摩擦系数降低,进而导致页岩脆性减弱.由于油基钻井完井液具有更大的自吸量、更强的碱性、更好的润滑性,其浸泡后的页岩脆性减弱幅度也就更大.

(3)相同工作液浸泡条件下,龙马溪组页岩脆性减弱幅度大于延长组页岩.和延长组页岩相比,龙马溪组页岩具有更小的接触角、更大的滤液自吸量、及更强的碱液侵蚀作用,因此,龙马溪组页岩层理缝扩展更加明显,微结构破坏更加严重,脆性减弱幅度更大.

| [1] | 中国国土资源部地质调查局. 中国页岩气资源调查报告(2014),2015.6.11. http://www.cgs.gov.cn/xwtzgg/jrgengxin/122749.htm (Ministry of Land and Resources of the People's Republic of China Geological Survey. Shale gas resources survey of China (2014),2015.6.11. http://www.cgs.gov.cn/xwtzgg/jrgengxin/122749.htm (in Chinese)) |

| [2] | 刘洪林,王红岩,刘人和等. 中国页岩气资源及其勘探潜力分析. 地质学报,2010,84(9):1374-1378 (Liu Honglin,Wang Hongyan,Liu Renhe,et al. China shale gas resources and prospect potential. Acta Geologica Sinica,2010,84(9):1374-1378 (in Chinese)) |

| [3] | 贾承造,郑民,张永峰. 中国非常规油气资源与勘探开发前景. 石油勘探与开发,2012,39(2):129-136 (Jia Chengzao,Zheng Ming,Zhang Yongfeng. Unconventional hydrocarbon resources in China and the prospect of exploration and development.Petroleum Exploration and Development,2012,39(2):129-136 (in Chinese)) |

| [4] | 邹才能,张国生,杨智等. 非常规油气概念、特征、潜力及技术 - 兼论非常规油气地质学. 石油勘探与开发,2013,40(4):385-399 (Zou Caineng,Zhang Guosheng,Yang Zhi,et al. Geological concepts,characteristics,resource potential and key techniques of unconventional hydrocarbon: On unconventional petroleum geology. Petroleum Exploration and Development,2013,40(4):385-399 (in Chinese)) |

| [5] | 刘致水,孙赞东. 新型脆性因子及其在泥页岩储集层预测中的应用. 石油勘探与开发,2015,42(1):1-8 (Liu Zhishui,Sun Zandong. New brittleness indexes and their application in shale/clay gas reservoir prediction. Petroleum Exploration and Development,2015,42(1):1-8 (in Chinese)) |

| [6] | Rickman R, Mullen M, Petre J, et al. A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the Barnett Shale. In: The 2008 SPE Annual Technical Conference and Exhibition, Denver, Colorado, USA, 21-24 September2008 |

| [7] | Holt RM,Fjær E,Stenebråten JF,et al. Brittleness of shales: relevance to borehole collapse and hydraulic fracturing. Journal of Petroleum Science and Engineering,2015,131:200-209 |

| [8] | Holt RM,Fjær EM,Nes OM,et al. A shaly look at brittleness. ARMA 11-366,2011 |

| [9] | 李庆辉,陈勉,金衍等. 页岩脆性的室内评价方法及改进. 岩石力学与工程学报,2012,31(8):1680-1685 (Li Qinghui,Chen Mian,Jin Yan,et al. Indoor evaluation method for shale brittleness and improvement. Chinese Journal of Rock Mechanics and Engineering,2012,31(8):1680-1685 (in Chinese)) |

| [10] | 王鹏,纪友亮,潘仁芳等. 页岩脆性的综合评价方法-以四川盆地W 区下志留统龙马溪组为例. 天然气工业,2013,33(12):48-53 (Wang Peng,Ji Youliang,Pan Renfang,et al. A Comprehensive evaluation methodology of shale brittleness:A case study from the Lower Silurian Longmaxi Fm in Block W,Sichuan Basin. Natural Gas Industry,2013,33(12):48-53 (in Chinese)) |

| [11] | 王宇,李晓,武艳芳等. 脆性岩石起裂应力水平与脆性指标关系探讨. 岩石力学与工程学报,2014,33(2):264-275 (Wang Yu,Li Xiao,Wu Yanfang,et al. Research on relationship between crack initiation stress level and brittleness indices for brittle rocks. Chinese Journal of Rock Mechanics and Engineering,2014,33(2):264-275 (in Chinese)) |

| [12] | 林冲. 富有机质页岩脆性评价及井壁失稳控制. [硕士论文]. 成都:西南石油大学,2015 (Lin Chong. Evaluation of organic-rich shale brittleness and wellbore instability control. [Master Thesis]. Chengdu:Southwest Petroleum University,2015 (in Chinese)) |

| [13] | Hucka V,Das B. Brittleness determination of rocks by different methods. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts,1974,11(10):389-392 |

| [14] | Altindag R. Correlation of specific energy with rock brittleness concepts on rock cutting. The Journal of the South African Institute of Mining and Metallurgy,2003,103(3):163-171 |

| [15] | 刁海燕. 泥页岩储层岩石力学特性及脆性评价. 岩石学报,2013,29(9):3300-3306 (Diao Haiyan. Rock mechanical properties and brittleness evaluation of shale reservoir. Acta Petrologica Sinica,2013,29(9):3300-3306 (in Chinese)) |

| [16] | Coates DF,Parsons RC. Experimental criteria for classification of rock substances. International Journal of Rock Mechanics and Mining Sciences& Geomechanics Abstracts,1966,3(3):181-189 |

| [17] | Tarasov B,Potvin Y. Universal criteria for rock brittleness estimation under triaxial compression. International Journal of Rock Mechanics and Mining Sciences,2013,59:57-69 |

| [18] | 周辉,孟凡震,张传庆等. 基于应力-应变曲线的岩石脆性特征定量评价方法. 岩石力学与工程学报,2014,33(6):1114-1122 (Zhou Hui,Meng Fanzhen,Zhang Chuanqing,et al. Quantitative evaluation of rock brittleness based on stress-strain curve. Chinese Journal of Rock Mechanics and Engineering,2014,33(6):1114-1122 (in Chinese)) |

| [19] | Protodyakonov MM. Mechanical properties and drillability of rocks. In: The 5th Symposium on Rock Mechanics,Twin Cities,USA,1962 |

| [20] | Yagiz S,Rostami J. Indentation test for the measurement of rock brittleness. ARMA 12-270,2012 |

| [21] | 蒋廷学,卞晓冰,苏瑗等. 页岩可压性指数评价新方法及应用. 石油钻探技术,2014,42(5):16-20 (Jiang Tingxue,Bian Xiaobing, Su Yuan,et al. A new method for evaluating shale fracability index and its application. Petroleum Drilling Techniques,2014,42(5):16-20 (in Chinese)) |

| [22] | Song L,Wang Y,Li Y. A novel experiment method of evaluating the brittleness of rock. SPE 167730,2014 |

| [23] | Jaeger JC,Cook NGW,Zimmerman RW. Fundamentals of Rock Mechanics (4th Edn). Blackwell Publ. Press,2007 |

| [24] | Fjær E,Holt RM,Horsrud P,et al. Petroleum Related Rock Mechanics (2nd Edn): Elsevier. 2008 |

| [25] | Yang Y,Hiroki S,Hows A,et al. Comparison of brittleness indices in organic rich shale formations. ARMA 13-403,2013 |

| [26] | Eseme E,Urai JL,Krooss BM,et al. Review of mechanical properties of oil shales: implications for exploitation and basin modeling. Oil Shale,2007,24(2):159-174 |

| [27] | MokhtariM,Alqahtani AA,Tutuncu AN. Impacts of stress,natural and induced fractures on mechanical properties of organic-rich shales. In: Unconventional Resources Technology Conference,12-14 August,Denver,Colorado,USA,2013 |

| [28] | 胡起,陈小宏,李景叶等. 干酪根对富含有机质页岩弹性性质的影响. 地球物理学进展,2014,29(2):748-753 (Hu Qi,Chen Xiaohong, Li Jingye,et al. The effect of kerogen on the elastic properties of organic-rich shales. Progress in Geophysics,2014,29(2):748-753 (in Chinese)) |

| [29] | Santarelli FJ,Carminati S. Do shales swell? A critical review of available evidence. In: SPE/IADC Drilling Conference,28 February-2 March,Amsterdam,Netherlands,1995 |

| [30] | Horsrud P,Bostrøm B,Sønstebø EF,et al. Interaction between shale and water-based drilling fluids: Laboratory exposure tests give new insight into mechanisms and field consequences of KCl contents. In: SPE Annual Technical Conference and Exhibition,27-30 September,New Orleans,Louisiana,1998 |

| [31] | 卢运虎,陈勉,安生. 页岩气井脆性页岩井壁裂缝扩展机理. 石油钻探技术,2012,40(4):13-16 (Lu Yunhu,Chen Mian,An Sheng. Brittle shale wellbore fracture propagation mechanism. Petroleum Drilling Techniques,2012,40(4):13-16 (in Chinese)) |

| [32] | 卢运虎,陈勉,金衍等. 钻井液浸泡下深部泥岩强度特征试验研究. 岩石力学与工程学报,2012,31(7):1399-1405 (Lu Yunhu, Chen Mian,Jin Yan,et al. Experimental study of strength properties of deep mudstone under drilling fluid soaking. Chinese Journal of Rock Mechanics and Engineering,2012,31(7):1399-1405 (in Chinese)) |

| [33] | 康毅力,皇凡生,游利军等. 钻井液浸泡页岩裂缝宽度的模拟及应用. 石油钻采工艺,2014,36(5):41-46 (Kang Yili,Huang Fansheng, You Lijun,et al. Simulation and application of shale fracture width immersed in drilling fluid. Oil Drilling& Production Technology,2014,36(5):41-46 (in Chinese)) |

| [34] | 刘向君,熊健,梁利喜等. 川南地区龙马溪组页岩润湿性分析及影响讨论. 天然气地球科学,2014,25(10):1644-1652 (Liu Xiangjun, Xiong Jian,Liang Lixi,et al. Analysis of the wettability of Longmaxi Formation Shale in the south region of Sichuan Basin and its influence. Natural Gas Geoscience,2014,25(10):1644-1652 (in Chinese)) |

| [35] | 梁利喜,熊健,刘向君. 水化作用和润湿性对页岩地层裂纹扩展的影响. 石油实验地质,2014,36(6):780-786 (Liang lixi,Xiong Jian,Liu Xiangjun. Effects of hydration swelling and wettability on propagation mechanism of shale formation crack. Petroleum Geology & Experiment,2014,36(6):780-786 (in Chinese)) |

| [36] | Li G,Liu H,Meng Y,et al. Challenges in deep shale gas drilling: A case study in Sichuan Basin. In: IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition,2012,9-11 July,Tianjin, China |

| [37] | 俞杨烽,康毅力,游利军等. 碱液侵蚀:一种泥页岩井壁失稳新机理. 石油学报,2013,34(5):983-988 (Yu Yangfeng,Kang Yili,You Lijun,et al. Alkali corrosion: a new mechanism of shale borehole instability. Acta Petrolei Sinica,2013,34(5):983-988 (in Chinese)) |

| [38] | You LJ,Kang YL,Chen ZX,et al. Wellbore instability in shale gas wells drilled by oil-based fluids. International Journal of Rock Mechanics and Mining Sciences,2014,72:294-299 |

| [39] | 衡帅,杨春和,郭印同等. 层理对页岩水力裂缝扩展的影响研究. 岩石力学与工程学报,2015,34(2):228-237 (Heng Shuai, Yang Chunhe, Guo Yintong, et al. Influence of bedding planes on hydraulic fracture propagation in shale formations. Chinese Journal of Rock Mechanics and Engineering,2015,34(2):228-237 (in Chinese)) |

| [40] | 衡帅,杨春和,张保平等. 页岩各向异性特征的试验研究. 岩土力学,2015,36(3):609-616 (Heng Shuai, Yang Chunhe, Zhang Baoping, et al. Experimental research on anisotropic properties of shale. Rock and Soil Mechanics,2015,36(3):609-616 (in Chinese)) |

| [41] | 陈昀, 金衍, 陈勉. 基于能量耗散的岩石脆性评价方法. 力学学报, 2015, 47(6): 984-993 (Chen Yun, Jin Yan, Chen Mian. A rock brittleness evaluation method based on energy dissipation. Chinese Journal of Theoretical and Applied Mechanics, 2015, 47(6): 984-993 (in Chinese)) |

| [42] | Kang YL, She JP, Hao Z, et al. Alkali erosion of shale by high-pH fluid: Reaction kinetic behaviors and engineering responses. Journal of Natural Gas Science and Engineering, 2016, 29: 201-210 |

| [43] | 俞杨烽. 富有机质页岩多尺度结构描述及失稳机理. [博士论文]. 成都:西南石油大学,2013 (Yu Yangfeng. M ulti-scale structure description and borehole instability mechanism of organic rich shale. [PhD Thesis]. Chengdu:Southwest Petroleum University,2013 (in Chinese)) |

2016, Vol. 48

2016, Vol. 48