金属多级类蜂窝的压溃行为研究1)

INVESTIGATION ON CRUSHING BEHAVIOR OF METAL HONEYCOMB-LIKE HIERARCHICAL STRUCTURES1)

中图分类号: V250.3

文献标识码: A

通讯作者:

收稿日期: 2018-12-13

网络出版日期: 2019-05-18

版权声明: 2019 力学学报期刊社 所有

基金资助:

展开

摘要

通过实验和数值模拟方法系统研究了单胞壁开孔金属多级类蜂窝与双胞壁开孔金属多级类蜂窝的压溃行为. 重点分析了试件尺寸、开孔位置、孔偏距和孔梯度等因素对多级类蜂窝力学性能的影响. 结果表明,多级类蜂窝的压溃过程可分为3个阶段:弹性变形、屈曲变形以及密实;单胞壁开孔多级类蜂窝的压溃过程趋向于渐近内凹压溃,而双胞壁开孔多级类蜂窝趋向于轴向压溃;试件尺寸对多级类蜂窝的力学行为有明显的影响,当胞元数达到一定数目时,其力学性能几乎与蜂窝胞元数无关. 单胞壁开孔多级类蜂窝的峰值应力大于双胞壁开孔多级类蜂窝的峰值应力,但其平均压溃应力小于双胞壁开孔多级类蜂窝的平均压溃应力;与传统蜂窝相比,蜂窝胞壁开孔设计降低了蜂窝材料的比吸能;孔偏距的存在导致单胞壁开孔多级类蜂窝的峰值应力降低,但随着孔偏距的增加其平均压溃应力呈先减低后增加趋势;多梯度孔设计对多级类蜂窝材料的力学性能有重要影响,与均匀孔多级类蜂窝相比,正梯度孔分布设计降低了多级类蜂窝峰值应力,但提高了其平均压溃应力;多梯度孔分布设计对多级类蜂窝的峰值应力和平均压溃应力影响不大.

关键词:

Abstract

Crushing behavior of metal honeycomb-like hierarchical structures of perforations on single walls (HHSPSW) and double walls (HHSPDW) was systematically investigated by using experiment and numerical simulation methods. Effects of specimen size, perforation location, perforation offsets and perforation gradient on the mechanical properties of honeycomb-like hierarchical structures were analyzed. The results show that the crushing process of honeycomb-like hierarchical structures can be divided into three deformation stages: elastic deformation, buckling deformation and densification. The deformation mode of honeycomb-like hierarchical structures of perforations on single walls is a progressive concave mode, while honeycomb-like hierarchical structures of perforations on double walls deform by axial crushing mode. Specimen sizes have significant influences on mechanical behavior of honeycomb-like hierarchical structures. Mechanical properties are almost independent of honeycomb numbers attaining a certain number. The peak stress of the honeycomb-like hierarchical structures of perforations on single walls is greater than that of honeycomb-like hierarchical structures of perforations on double walls, while its mean crushing stress is less than that of honeycomb-like hierarchical structures of perforations on double walls. Comparing to the traditional honeycombs, the design of perforations on honeycomb walls reduces the specific energy absorption of the honeycombs. Perforation offsets result in decreasing the peak stress of the honeycomb-like hierarchical structures of perforations on single walls, while the mean crushing stress firstly decreases and then increases with increasing the perforation offset. Honeycomb-like hierarchical structures with positive gradient perforations reduce the peak stresses while improve the mean crushing stress comparing to honeycomb-like hierarchical structures with the uniform perforations. The design of muti-gradient perforation distributions on honeycomb walls has small influence on the peak stress and the mean crushing stress.

Keywords:

引 言

蜂窝材料作为一种比较理想的轻质多孔材料,具有较高的比强度、比刚度,以及较好的隔音、隔热、耐缓冲等优点,被广泛地应用于航天航空、交通、包装、建筑等领域[1-3]. 蜂窝材料根据基底材料的类型可分为铝蜂窝[4-5]、钢蜂窝[6]及纸蜂窝[7-8]等;根据胞元的几何形状,可以分为六边形蜂窝[4-5]、方形蜂窝[9-10]、圆形蜂窝[11-12]、Kagome蜂窝[13]、自相似蜂窝[14-15]等,其中六边形蜂窝是最常见的蜂窝材料之一.

对于六边形蜂窝的力学性能,国内外学者做了大量的研究.Wierzbicki[16]基于能量守恒给出了准静态载荷作用下蜂窝的平均压溃应力和胞壁折叠波波长关于蜂窝几何参数的关系式.刘强等[17]基于小变形理论及材料各向同性假设,给出了六边形金属蜂窝材料弹塑性屈曲力学模型.罗昌杰等[18]以"Y"字形简化单元为研究对象,采用Mises屈服准则和Tresca屈服准则推导了蜂窝材料在准静态压缩载荷下平均压溃应力的理论模型,并通过实验验证了模型的有效性.张卫红等[19]给出了六边形蜂窝的材料等效面外剪切模量及其尺寸效应的圆筒扭转力学模型和扭转能量法.Yamashita等[2]、Zhang等[10]采用实验与数值模拟方法,研究了不同胞壁厚度和拉伸角的影响,发现拉伸角为120$^\circ$的蜂窝材料的力学性能最优.Wu和Jiang[20]对蜂窝材料在准静态和动态载荷条件下的面外压缩响应进行了实验研究,发现基底材料、胞元尺寸和加载速度对蜂窝的力学性能有影响. Xu等[5,21]认为蜂窝材料的平均压溃应力和密实应变与蜂窝材料的相对密度呈指数关系.Wang等[22]通过实验与数值模拟研究认为,只有初始冲击速度小于30,m/s时,蜂窝材料的平均压溃应力会随冲击速度的增大而明显增大.Sun等[23]通过数值模拟研究发现当蜂窝结构参数一定时,平均压溃应力随加载速度增大,并给出了相关的经验公式.Tao等[24-25]采用霍普金森杆对蜂窝材料的动态压缩强度进行了实验研究,发现应变率效应对蜂窝材料的平均压溃应力有明显的影响,并在传统冲击理论的基础上,引入Cowper-Symonds关系,得到了率相关表达式,从而更为准确地预测动态载荷下的平均压溃应力.Wu和Jiang[20]认为试件尺寸对蜂窝的面外压缩强度几乎无影响,而Xu等[5]通过实验研究认为,当蜂窝胞元数大于9$\times$9时,平均压溃应力趋于稳定.

蜂窝材料通常以夹芯结构出现在诸多领域,而夹芯结构是由上下面板及蜂窝芯材组成,根据蜂窝芯材胞孔轴线与面板的相对位置关系,可分为蜂窝面内夹芯结构[26](轴线与面板平行)与蜂窝面外夹芯结构[27-28](轴线与面板垂直). 蜂窝面内夹芯结构可以实现芯材中的热/流体交换,但承载能力较差;蜂窝面外夹芯结构承载能力好,但无法实现芯材中的热/流体交换. Landi等[29-30]在传统蜂窝材料的胞壁上开孔,形成了结构/功能一体化的多级类蜂窝材料. 多级类蜂窝应用在蜂窝面外夹芯结构中可提高结构承载能力,并具备热量及流体交互流通的功能,可应用于风力发电机叶片及诸多冷却装置、缓冲吸能结构中. Wang等[31-32]利用实验与数值模拟方法对单胞壁开孔多级类蜂窝的压溃行为和吸能特性进行了研究.

由于其独特的结构特点,多级类蜂窝具有广阔的工程应用前景,但目前对多级类蜂窝的相关研究相对较少,已有研究仅仅关注了单胞壁开孔金属多级类蜂窝的准静态力学性能. 本文将采用实验和数值模拟的方法,系统研究单胞壁开孔多级类蜂窝与双胞壁开孔多级类蜂窝的准静态压溃行为,分析试件尺寸、开孔位置、孔偏距和孔梯度等因素对多级类蜂窝力学性能的影响,并采用峰值应力,平均压溃应力等指标评价该创新构型多级蜂窝材料的力学性能.

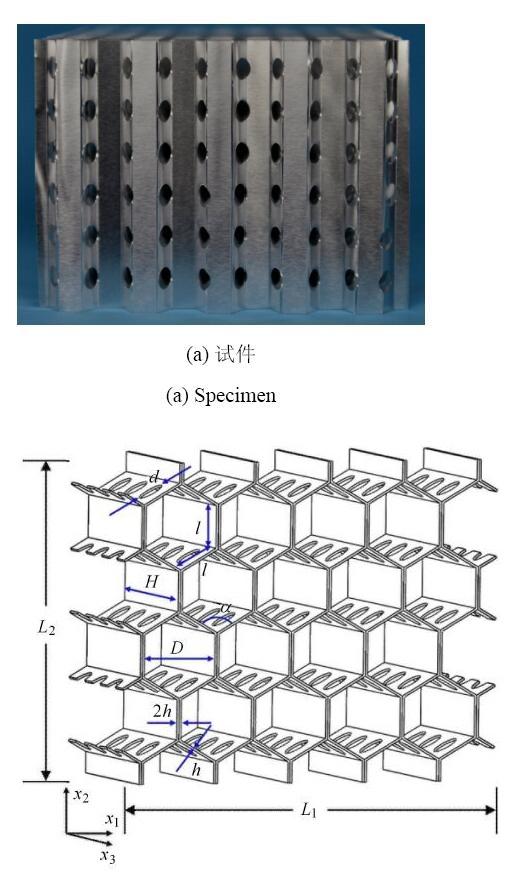

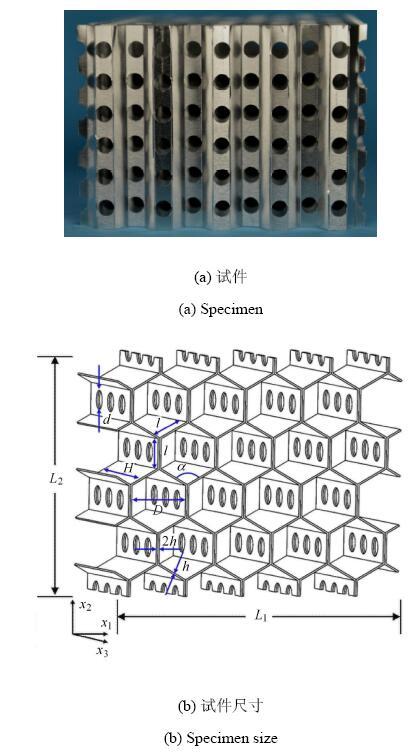

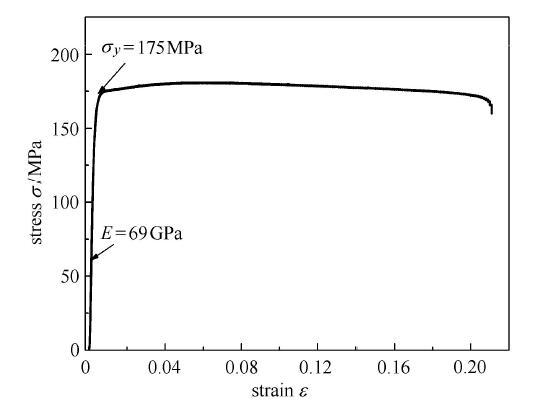

1 实验试件

准静态实验中选用了由西安雅西复合材料有限公司提供的多级类蜂窝试件,其制备采用的是拉伸成型法,主要分五个步骤:第一步是铝箔表面油处理;第二步是铝箔涂胶;第三步是铝箔的叠加和固化;第四步是切条,打孔;第五步是拉伸成型.根据多级类蜂窝胞壁孔位置的不同,可分为单胞壁开孔多级类蜂窝 (honeycomb-like hierarchical structure ofperforations on single walls, HHSPSW)和双胞壁开孔多级类蜂窝(honeycomb-like hierarchical structure ofperforations on double walls, HHSPDW),如图1和图2所示,其密度均为31.04,kg/m$^{3}$,$x_{1}$为垂直于双胞壁面的方向,$x_{2}$为平行于双胞壁面的方向,$x_{3}$为蜂窝面外方向;单胞壁厚度$h$为0.05,mm,双胞壁厚度2$h$为0.1,mm,胞壁宽度$l$为5.5,mm,胞壁孔孔径$d$为5,mm,拉伸角 $\alpha $为120$^\circ$,胞元内切圆直径$D$为9.53,mm,蜂窝高度$H$为60,mm,$x_{3}$方向上的胞壁孔数均为6.多级类蜂窝基体材料Al3003-H18的密度为2700,kg/m$^{3}$,弹性模量为69,GPa,屈服强度为175,MPa,泊松比为0.33,如图3所示,给出了Al3003-H18单轴拉伸的应力$\!$-$\!$-$\!$应变曲线.

图1 单胞壁开孔多级类蜂窝

Fig. 1 Honeycomb-like hierarchical structure of perforations on single walls

图2 双胞壁开孔多级类蜂窝

Fig. 2 Honeycomb-like hierarchical structure of perforation on double walls

图3 Al3003-H18单轴拉伸应力$\!$-$\!$-$\!$应变曲线

Fig. 3 Al3003-H18 Uniaxial tensile stress-strain curve

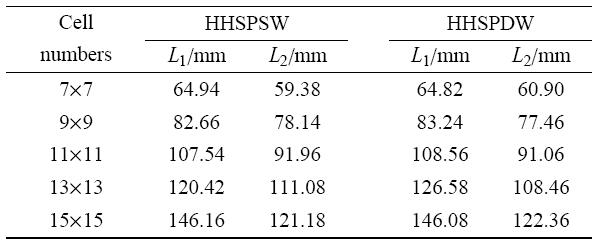

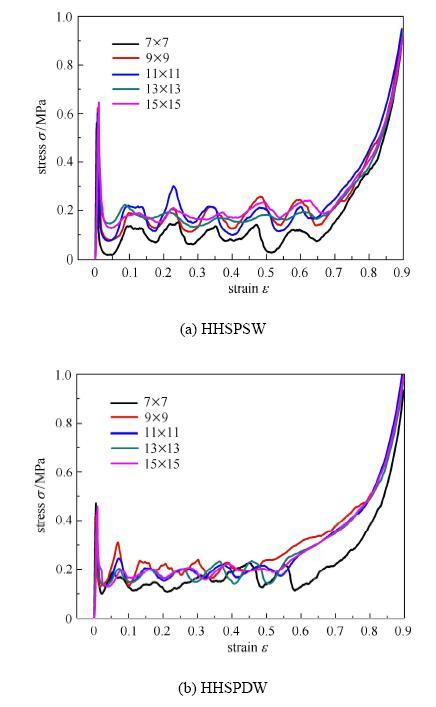

为研究试件尺寸对多级类蜂窝准静态压溃行为的影响,分别设置了5种不同尺寸的单/双胞壁开孔多级类蜂窝,其中胞元数分别为7$\times$7, 9$\times $9, 11$\times $11, 13$\times $13, 15$\times$15,具体试件尺寸,如表1所示.

2 实验过程

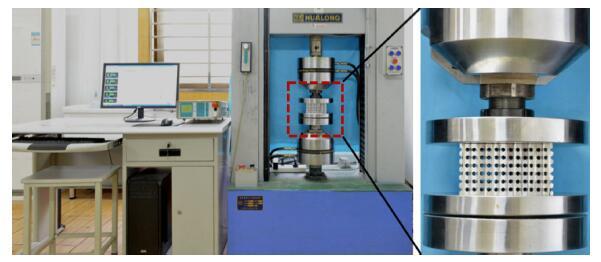

准静态压缩实验采用如图4所示的电子万能试验机(WDW-1000)进行,实验时将试件置于固定压盘中心位置,保持压头以恒定压缩速度2\,mm/min进行压缩,并通过测试系统记录载荷$\!$-$\!$-$\!$位移曲线,同时记录试件的压溃变形过程.

3 实验结果与讨论

3.1 压溃模式

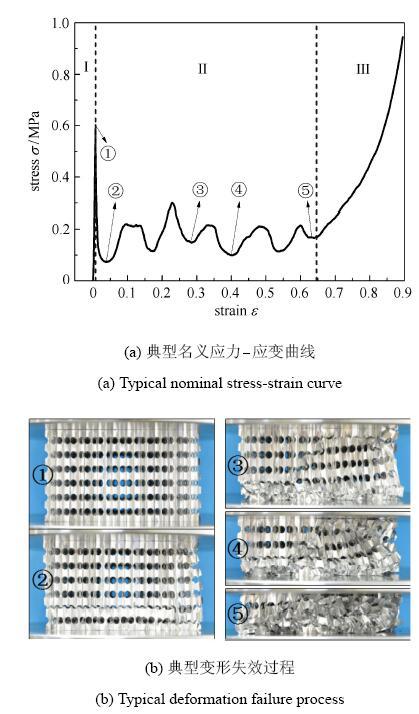

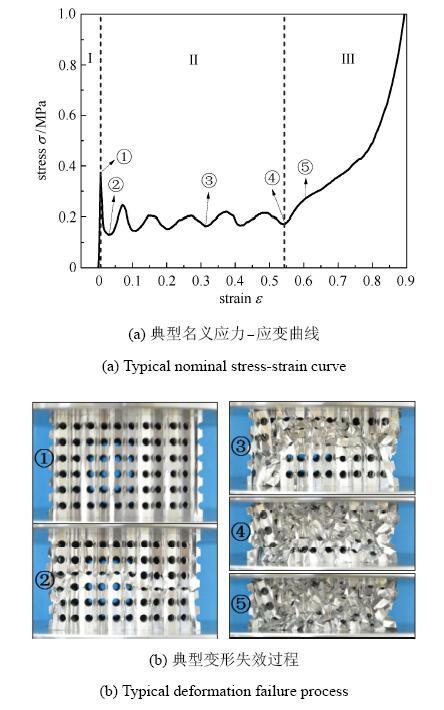

图5和图6分别给出了胞元数为11$\times$11的单/双胞壁开孔多级类蜂窝在准静态载荷作用下的典型名义应力$\!$-$\!$-$\!$应变曲线及压溃变形过程. 根据名义应力$\!$-$\!$-$\!$应变曲线及压溃变形过程,将单/双胞壁开孔多级类蜂窝的准静态压缩过程分为3个阶段:弹性变形阶段、屈曲变形阶段以及密实阶段.

第Ⅰ阶段:弹性变形阶段.在准静态载荷作用的初始阶段,多级类蜂窝处于弹性变形范围,没有出现明显的屈曲现象,名义应力$\!$-$\!$-$\!$应变曲线近似为一条直线.

第Ⅱ阶段:屈曲变形阶段.多级类蜂窝在弹性变形之后开始出现塑性变形,由于胞壁开孔的影响,开孔层相对强度较弱,最先发生屈曲变形,同时名义应力$\!$-$\!$-$\!$应变曲线会出现明显的波动现象. 单胞壁开孔多级类蜂窝的屈曲压溃过程中,试件靠近压盘固支端的孔层发生压溃,随着变形量的增大,整体出现明显的内凹现象,称之为渐近内凹压溃;双胞壁开孔多级类蜂窝的屈曲压溃过程中,试件中部孔层发生压溃,沿孔层向试件底端发生压溃,随后向试件顶端发生压溃,称之为轴向压溃.这是由于单胞壁开孔多级类蜂窝的胞壁孔开在单胞壁上,单胞壁的强度被削弱,孔层中单、双胞壁的强度差距加大,变形易于发生在强度更弱的单胞壁上,因此会逐渐出现渐近内凹压溃现象,而双胞壁开孔多级类蜂窝的胞壁孔开在双胞壁上,双胞壁的强度被削弱,孔层中单、双胞壁的强度更加趋近,进而更易于发生轴向压溃变形.其次,多级类蜂窝在制备过程中可能会形成诸多缺陷,如蜂格的不规则性、胞壁厚度的不一致性以及孔偏置等,都会对其初始失效模式造成影响,因此压缩过程中单/双胞壁开孔多级类蜂窝会在不同的位置先发生压溃.

第Ⅲ阶段:密实阶段.随着孔层屈曲变形的结束,多级类蜂窝逐渐进入密实阶段,应力曲线逐渐上升,蜂窝刚度迅速增大,承载能力迅速增加,而蜂窝的变形空间则大大减小.

3.2 应力$\!$-$\!$-$\!$应变曲线

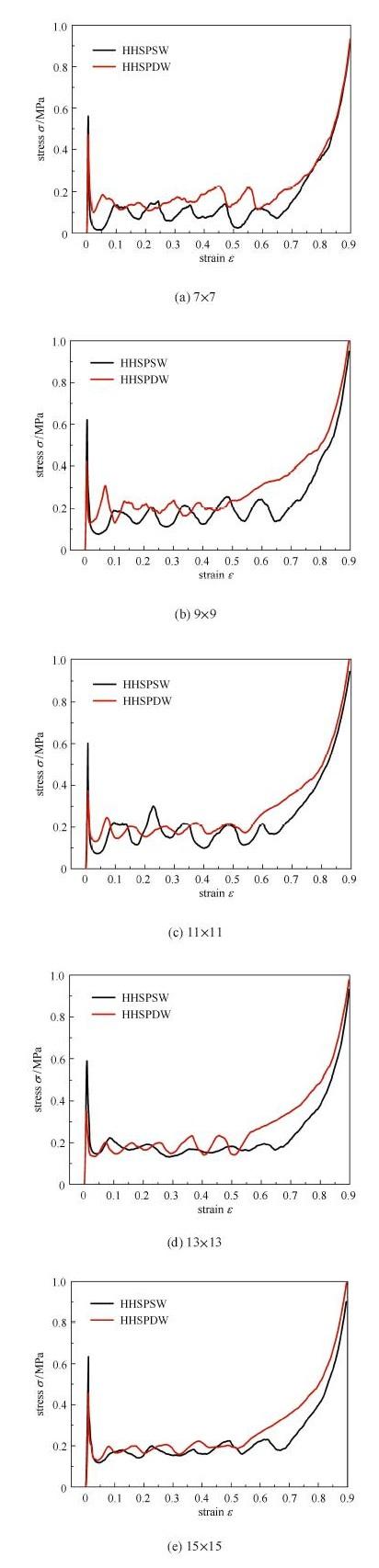

图7分别给出了不同试件尺寸对应的单/双胞壁开孔多级类蜂窝准静态压缩名义应力$\!$-$\!$-$\!$应变曲线. 从图中可以看到,胞元数较小时(7$\times $7, 9$\times$9),两种多级类蜂窝的名义应力$\!$-$\!$-$\!$应变曲线受尺寸影响较大;继续增加胞元数(11$\times $11, 13$\times $13, 15$\times$15)时,名义应力$\!$-$\!$-$\!$应变曲线逐渐趋于稳定,这说明试件尺寸对其准静态压缩力学性能有明显的影响. 这是由于多级类蜂窝自由边界胞壁与试件中心部位的胞壁相比,所受约束较弱,易于变形,几乎不具备承载能力;随着试件尺寸的增大,自由边界胞壁的占比下降,多级类蜂窝的力学性能会逐渐趋于稳定.

进一步研究发现,相同试件尺寸下双胞壁开孔多级类蜂窝的峰值应力要比单胞壁开孔多级类蜂窝的小,而屈曲阶段的应力要比单胞壁开孔多级类蜂窝的大,如图8所示. 与单胞壁开孔多级类蜂窝相比,双胞壁开孔多级类蜂窝的孔层强度较低,因此其初始峰值应力相对较小. 同时,双胞壁开孔多级类蜂窝孔层的强度分布更加均匀,结构趋向于轴向压溃,单胞壁开孔多级类蜂窝孔层强度差异较大,结构更易发生渐近内凹压溃,导致结构的承载能力下降,因而单胞壁开孔多级类蜂窝屈曲阶段的应力相对较小.

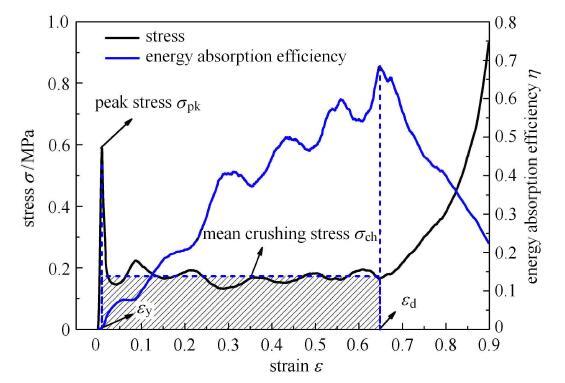

3.3 平均压溃应力

平均压溃应力(mean crushing stress)是反映多孔材料承载能力的重要参数指标. 通过能量吸收效率法$^{[24\hbox{-}25,33]}$,可获得单/双胞壁开孔多级类蜂窝准静态压缩下的平均压溃应力,如图9所示. 蜂窝材料在单轴压缩过程中任意应变量下的能量吸收效率可表示为

$$\eta \left( \varepsilon \right) = \dfrac{1}{\sigma \left( \varepsilon\right)}\int_0^\varepsilon {\sigma \left( \varepsilon \right) }\,\varepsilon (1)$$

密实应变可通过式(2)进行定义

$$\left. {\dfrac{ \eta \left( \varepsilon \right)}{\varepsilon }}\right|_{\varepsilon _{\rm d} } = 0 (2)$$

则平均压溃应力可表示为

$$\sigma _{\rm ch} = \dfrac{1}{\varepsilon _{\rm d} - \varepsilon _{\rm y} }\int_{\varepsilon _{\rm y} }^{\varepsilon _{\rm d} } {\sigma \left( \varepsilon \right)} \,\varepsilon (3)$$

其中, $\varepsilon_{\rm y}$为屈服应变, $\varepsilon _{\rm d}$为密实应变.

图10给出了单/双胞壁开孔多级类蜂窝平均压溃应力随胞元数的变化规律. 当胞元数大于11$\times $11时两类多级类蜂窝的平均压溃应力几乎与胞元数无关,且单胞壁开孔多级类蜂窝的平均压溃应力小于双胞壁开孔多级类蜂窝的.

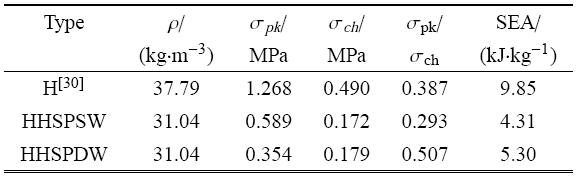

进一步采用已有文献相同规格传统蜂窝的实验结果[33]与多级类蜂窝进行了对比分析,如表2所示.与传统蜂窝(honeycomb,H)相比,单/双胞壁上开孔均降低了蜂窝材料的峰值应力和平均压溃应力,而双胞壁开孔的峰值应力降低最为明显.单胞壁开孔多级类蜂窝降低了平均压溃应力与峰值应力的比值,双胞壁开孔多级类蜂窝提升了平均压溃应力与峰值应力的比值,说明双胞壁开孔多级类蜂窝的名义应力$\!$-$\!$-$\!$应变曲线更为平稳. 单/双胞壁开孔多级类蜂窝的比吸能(specific energy absorption,SEA)小于传统蜂窝的,说明胞壁开孔设计降低了蜂窝材料比吸能[7]

$$SEA = {\int_0^\delta {F\left( \delta \right)} \,\delta }/ M (4)$$

其中,$F$为轴向压缩载荷,$M$为试件质量, $\delta $ 为压缩变形量.

表2 蜂窝的力学性能参数(胞元数为13$\times $13)

Table 2 Mechanical property parameters of honeycombs (cell numbers: 13$\times $13)

|

4 数值模拟

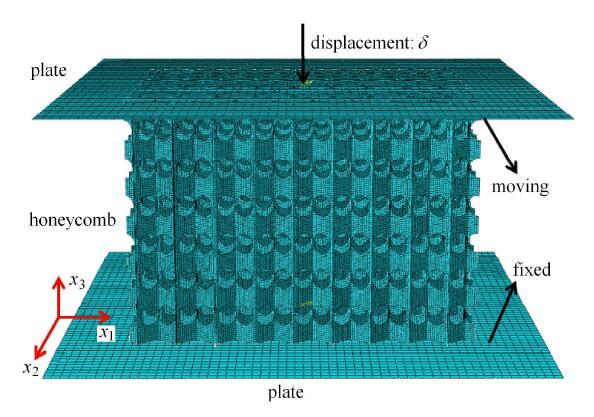

4.1 模型及验证

采用有限元分析软件Abaqus6.13建立了数值模型,如图11所示. 模型由上、下压板以及多级类蜂窝组成,多级类蜂窝尺寸与实验保持一致. 多级类蜂窝采用4节点壳单元(S4R)进行网格划分,双层胞壁之间采用理想粘接,胞元数为11$\times$11. 上下面板用离散刚体模拟,下压板施加固定约束,上压板在$x_{3}$方向施加位移约束并限制其在$x_{1}$和$x_{2}$方向的位移. 多级类蜂窝与压板间的接触设定为通用接触,接触摩擦因子为0.1,基体材料特性,如图3所示.

为了保证模拟精度的同时降低计算成本,对有限元模型进行了网格敏感性分析,如图12所示. 从图中可以看到,网格单元大于3.9$\times$10$^{5}$(网格尺寸为0.5\,mm)时,峰值应力与平均压溃应力几乎保持为常数. 因此,在模型验证与参数讨论过程中,将会采用相同的网格尺寸进行数值分析.

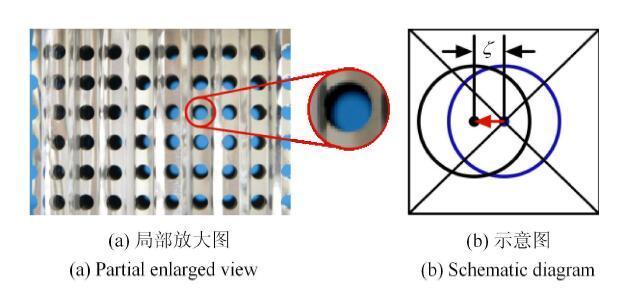

多级类蜂窝制备过程中可能存在各种各样的缺陷,如蜂格的不规则性、胞壁厚度的不一致性以及孔偏置等.实验中发现多级类蜂窝存在明显的孔偏置现象,如图13所示,$\zeta $为孔偏距.根据实际情况取孔偏距为0.50,mm,进行了接触摩擦因子分析及模型验证.

图14给出了单胞壁开孔多级类蜂窝在不同摩擦因子$f$下的名义应力$\!$-$\!$-$\!$应变曲线.由图可知,接触摩擦因子对名义应力$\!$-$\!$-$\!$应变影响不大,所以在本文计算模型中均取摩擦因子$f = 0.1$.

图14 名义应力$\!$-$\!$-$\!$应变曲线(HHSPSW)

Fig. 14 Nominal stress-strain curves (HHSPSW)

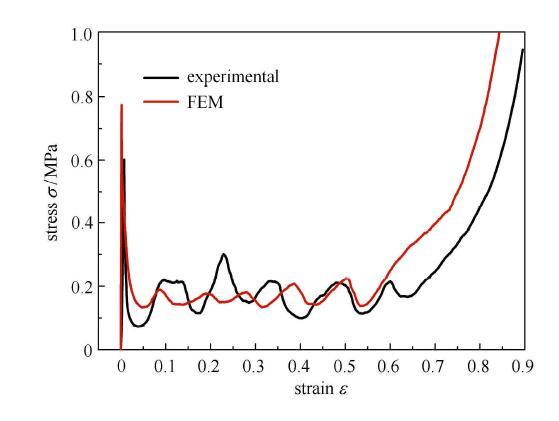

图15与图16对胞元数为11$\times $11的多级类蜂窝的实验与数值计算结果进行了对比.从图中可以看到,单胞壁开孔多级类蜂窝的实验和数值计算名义应力$\!$-$\!$-$\!$应变曲线与压溃过程吻合较好,说明数值模型是合理的.

图15 实验与数值计算结果对比(HHSPSW)

Fig. 15 Comparison between experimental and numerical results (HHSPSW)

图16 实验与数值计算结果对比(HHSPSW)

Fig. 16 Comparison between experimental and numerical results of HHSPSW

4.2 孔偏距影响

为了分析孔偏距对多级类蜂窝力学性能的影响,建立胞元数为11$\times$11的单胞壁开孔多级类蜂窝数值模型进行计算和分析.

图17给出了孔偏距为0.00,mm, 0.25,mm, 0.50,mm, 0.75,mm和1.00,mm时对应的单胞壁开孔多级类蜂窝的名义应力$\!$-$\!$-$\!$应变曲线. 由图中可以看到,由于孔偏距的存在,导致单胞壁开孔多级类蜂窝的峰值应力降低. 随着孔偏距的增大,单胞壁开孔多级类蜂窝会逐渐转变为单双胞壁开孔的混合型多级类蜂窝,其名义应力$\!$-$\!$-$\!$应变曲线波动相对较小,这可能是由于孔偏距的存在降低了单胞壁开孔多级类蜂窝微结构的刚度.

图17 名义应力$\!$-$\!$-$\!$应变曲线(HHSPSW)

Fig. 17 Nominal stress-strain curves (HHSPSW)

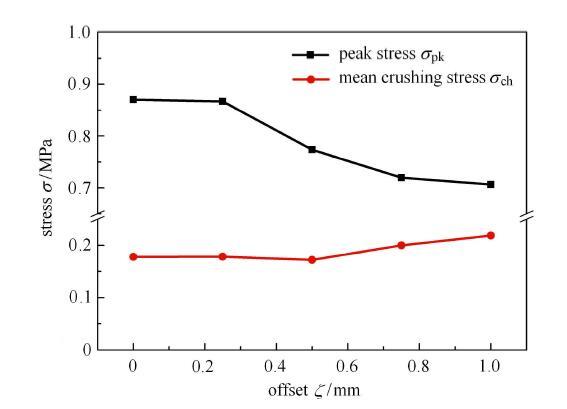

图18给出了单胞壁开孔多级类蜂窝的峰值应力与平均压溃应力随孔偏距的变化规律.从图中可以看到,孔偏距对多级类蜂窝的 峰值应力和平均压溃应力均有明显的影响,峰值应力整体呈下降趋势,平均压溃应力呈先降低后上升趋势,这可能是由于随着孔偏距的增大,单胞壁开孔多级类蜂窝会逐渐转变为单双胞壁开孔的混合型多级类蜂窝所导致的结果.孔偏距小于0.25\,mm时,单胞壁开孔多级类蜂窝的峰值应力与平均压溃应力均维持稳定.

4.3 孔梯度设计

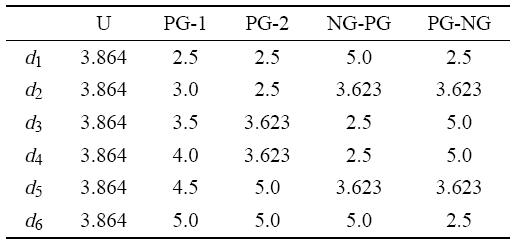

为了研究多级类蜂窝胞壁孔对其准静态力学性能的影响,对单胞壁开孔多级类蜂窝进行了孔结构优化设计,图19给出了5种不同的胞壁孔形式示意图. 其中,在均匀孔(uniform,U)多级类蜂窝的基础上改变胞壁孔的大小,得到第一类正梯度孔(positivegradient-1, PG-1)和第二类正梯度孔(positive gradient-2,PG-2)多级类蜂窝;在PG-2型的基础上进一步改变开孔排布顺序可得第一类多梯度孔(negativegradient-positive gradient, NG-PG)和第二类多梯度孔(positivegradient-negative gradient,PG-NG)多级类蜂窝. 5种不同单胞壁开孔多级类蜂窝密度保持一致,均为34.25,kg/m$^{3}$,胞壁孔孔径尺寸见表3.

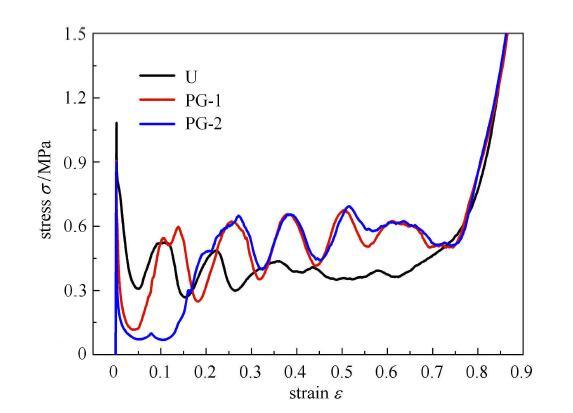

图20给出了U、PG-1和PG-2单胞壁开孔多级类蜂窝的名义应力$\!$-$\!$-$\!$应变曲线. 从图中可以看到,三类多级类蜂窝的名义应力$\!$-$\!$-$\!$应变曲线存在明显差异,与PG-1和PG-2相比,U的峰值应力较大,屈曲阶段的整体应力较小.

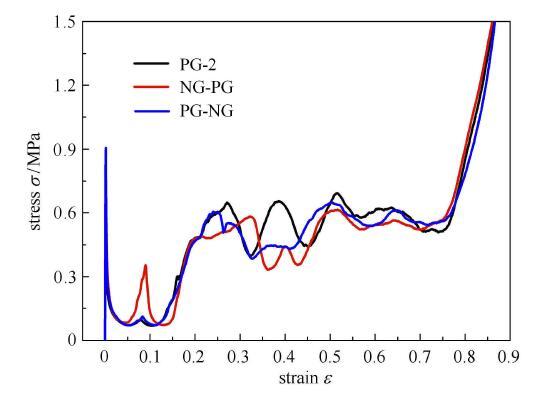

图21给出了PG-2型,NG-PG型和PG-NG型单胞壁开孔多级类蜂窝的名义应力$\!$-$\!$-$\!$应变曲线. 由图可知,胞壁孔大小相同的情况下,孔分布形式对多级类蜂窝的峰值应力和屈曲阶段的应力影响不大.

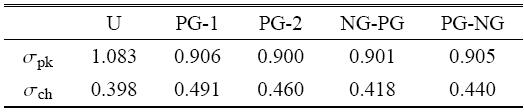

由表4进一步对比分析发现,均匀孔多级类蜂窝的峰值应力最大,但其平均压溃应力小于孔梯度分布形式的多级类蜂窝;PG-2, NG-PG,PG-NG的峰值应力均要比PG-1低0.7%以下,平均压溃应力均小14.9%以下,但多梯度孔分布设计对多级类蜂窝的峰值应力与平均压溃应力影响较小.

表4 多级类蜂窝力学性能参数

Table 4 Mechanical property parameters of honeycomb-like hierarchical structures

|

5 结 论

本文利用实验和数值模拟对金属多级类蜂窝的压溃行为进行了系统研究,分析了试件尺寸、开孔位置、孔偏距和孔梯度对多级类蜂窝力学性能的影响.

(1)金属多级类蜂窝准静态压溃过程可分为3个阶段:弹性变形阶段、塑性屈曲阶段、密实阶段. 单胞壁开孔多级类蜂窝的压溃过程趋向于渐近内凹压溃,双胞壁开孔多级类蜂窝的趋向于轴向压溃.

(2)多级类蜂窝的准静态压缩力学行为受试件尺寸影响较大,当胞元数大于11$\times$11时,其力学性能与蜂窝胞元数无关. 与传统蜂窝相比,胞壁开孔设计降低了蜂窝材料的比吸能.

(3)孔偏距的存在,导致单胞壁开孔多级类蜂窝的峰值应力有所降低,但随着孔偏距的增加其平均压溃应力呈先减低后增加趋势.

(4)在密度相同的情况下,与均匀孔多级类蜂窝相比,正梯度孔分布设计降低了多级类蜂窝峰值应力,但提高了其平均压溃应力;多梯度孔分布设计对多级类蜂窝的峰值应力和平均压溃应力影响不大.

The authors have declared that no competing interests exist.

参考文献

| [1] |

Lightweight materials and structures . |

| [2] |

Impact behavior of honeycomb structures with various cell specifications---numerical simulation and experiment .

The bare aluminum alloy (A5052) honeycomb is compressed in the longitudinal direction of the cell. Effect of the cell shape and the foil thickness on crush behavior is investigated by the numerical simulation using an explicit FEM code DYNA3D. Impact experiment using a drop-hammer apparatus whose impact velocity is 10 m/s and the corresponding quasi-static one are also performed. In the impact experiment, compressive stress increases with the hammer travel due to the air enclosed in the honeycomb cells. However, the nominal stress at the incipient compression is very similar for both the cases. In computation, numerical model of one ‘Y’ cross-sectional column is used and the impact velocity is 10 m/s. Internal angle of branch in ‘Y’ cross-section ranges from 30° to 180°. The numerical result shows that the cyclic buckling mode takes place in every case and that the crush strength is higher for smaller branch angle. It increases with the foil thickness. However, when the crush strength is evaluated with respect to the net cross-section of the material part only, it attains the maximum value when the cell shape is of regular hexagon. Numerical results are well consistent with the corresponding experimental ones.

|

| [3] |

|

| [4] |

Dynamic crushing strength of hexagonal honeycombs .

Based on the repeatable collapsing mechanism of cells’ structure under dynamic crushing, an analytical formula of the dynamic crushing strength of regular hexagonal honeycombs is derived in terms of impact velocity and cell walls’ thickness ratio. It is consistent with the equation obtained from the shock wave theory that regards cellular material as continuum, in which the key parameter is approximately measured from the “stress–strain” curve of the cellular material. The effect of unequal thickness of cell walls on the honeycomb's dynamic crushing strength is discussed, and the result shows that the dynamic crushing strength of the hexagonal honeycomb with some double-thickness walls is about 1.3 times of that of the hexagonal honeycomb without double-thickness wall. All of the analytical predictions are compared with the numerical simulation results, showing good agreements.

|

| [5] |

Experimental study of the out-of-plane dynamic compression of hexagonal honeycombs .

The out-of-plane crushing behaviour of four types of aluminium hexagonal honeycombs was extensively investigated over a wide range of strain rates where each test was conducted at a constant compressive velocity. The effects of specimen dimensions, relative density, strain rate and honeycomb cell size on the mechanical properties of honeycombs were studied. It was demonstrated that the mean plateau force was linearly related to the specimen dimensions. However, the calculated plateau stress varied with specimen dimensions and a minimum of 9脳9cells should be used in order to represent the bulk properties of honeycombs. A large strength enhancement of honeycombs was observed when the relative density and strain rate increased. The tangent modulus also increased towards the end of the crushing process, especially for those honeycombs with small values of wall thickness to edge length ratio (t/l). Semi-empirical relations were obtained to describe the effects of relative density (t/l ratio) and strain rate on the plateau stress. The difference in deformation patterns for honeycombs between quasi-static and dynamic loading conditions was also discussed.

|

| [6] |

Plastic analyses of thin-walled steel honeycombs with re-entrant deformation style .

To get an ideal energy absorbing structure, which has low initial peak force but high energy absorbing efficiency, non-entrant and re-entrant honeycombs have re-entrant deformation styles were designed and fabricated. In-plane compression experiments and numerical simulations were carried out to reveal the progressive crushing process and the energy absorption level. In the crushing, the re-entrant honeycomb contracts laterally and has the potential to turn to a triangular lattice structure. The initial yield force of these honeycombs is not high but the stress after yield keeps high level and the plateau in stable. It is found to get a stable deformation curve the vertical wall must be thicker. Based on the crushing modes, plastic models were built to predict the mean crushing force (MCF) and they fit the test data very well. It is found that the re-entrant honeycomb has better energy absorption than the non-entrant honeycomb. Adopting re-entrant design, the MCF is even greater than the peak force, which benefits engineering design for energy absorbing structures in devices which requires smaller peak force but greater energy absorption.

|

| [7] |

Mechanical performance and energy absorption properties of structures combining two Nomex honeycombs .

To study the mechanical performance and energy absorption property of two-layer Nomex honeycombs of different types, compressive tests on different combinations were conducted and the experimental results compared with those from tests on single honeycomb specimens. The types of combinations include combinations of two honeycombs of the same specification without a clapboard (HSSWC), combinations of two honeycombs of the same specification containing a clapboard (HSSCC), combinations of two honeycombs of different specification without a clapboard (HDSWC), and combinations of two honeycombs of different specification containing a clapboard (HDSCC). The results showed that different combinations were suitable for different situations. It was advisable to apply the combinations containing clapboards as crashworthy structures which call for large collapse stress. It is necessary to reduce the initial collapse stress in the damping and energy-absorbing structures, so combinations without clapboards can be used. The structures combining different honeycomb specifications can be adopted to control the ordered deformation and ladder energy levels.

|

| [8] |

Experimental and numerical investigation of the effect of entrapped air on the mechanical response of Nomex honeycomb under flatwise compression . |

| [9] |

Dynamic compression of square honeycomb structures during underwater impulsive loading . |

| [10] |

Experimental and numerical studies on the crush resistance of aluminum honeycombs with various cell configurations .

Commercial aluminum honeycombs with various cell configurations are experimentally tested to study the influence of cell number and central angle on the out-of-plane crush resistance of the structures. The boundary effect is found to have significant impact on the crush strength of the structure when the number of cells is small and the central angle is observed to get a difference less than 10% in the strength of the honeycombs. Numerical analyses based on whole honeycomb model and Y-shaped element model are carried out to simulate the crush and deformation process of the specimens. The adhesive bonding of the double thickness foil is considered in the simulation and the numerical results show good agreement with the experimental data and theoretical predictions. Finally, the reason for the small influence of central angle on the out-of-plane strength of honeycombs is investigated and the interaction effect between wall thickness and central angle is believed to account for it. (C) 2014 Elsevier Ltd. All rights reserved.

|

| [11] |

Dynamic axial crush response of circular cell honeycombs .

The dynamic axial crush response of circular cell polycarbonate honeycombs was studied for 3-cell and 7-cell specimens experimentally and through finite-element (FE) simulation. The experiments were conducted using two loading methods: (i) the wave loading device (WLD) method and (ii) the direct impact method (DIM). The specimens were subjected to crush velocities of about 126500065mm65s611 in the WLD method and 500065mm65s611 in the DIM. The two methods were used to obtain a fairly wide range of input velocities. The collapse sequence and displacement information of the specimens were captured using a high-speed camera. The mode of collapse was through progressive concertina-diamond fold formation over a fairly constant state of load, which is referred to as the crush load. The crushing was simulated using an explicit FE analysis using ABAQUS, with geometrically imperfect 3-cell and 7-cell honeycomb models that incorporated the rate-dependent properties of polycarbonate. The FE results were found to agree well with the experimental results in terms of overall force–displacement plots, thus providing a basis to extract energy absorption estimates from the models and to draw comparisons between the 3-cell and 7-cell response behaviour. Moreover, the dynamic crush results were compared against a quasi-static axial crush response to demonstrate the presence of rate effects.

|

| [12] |

Dynamic crushing of the circular-celled honeycombs under out-of-plane impact .

61An analytical expression of circular honeycombs’ crushing stress is deduced.61The HP honeycombs show superiority in the energy absorption.61The energy absorption capacity depends on the constraints around cells.61The HP honeycomb shows the least sensitivity to the impact velocity.

|

| [13] |

2D周期蜂窝结构面内静动态压缩力学行为研究 .

基于``平板开缝-装配-焊接''工艺制备了以高聚物为基体的Kagome等蜂窝结构,并开展了Kagome, 正三角形和菱形蜂窝结构的面内准静态压缩力学行为实验研究,实验过程中应用CCD图像采集系统和图像相关法对试件进行了全场位移监测. 另外对比传统正六边形蜂窝,采用数值分析技术,模拟了低速冲击下不同蜂窝结构坍塌行为. 实验结果和数值模拟均揭示了在材料用量和结构尺寸完全相同的情况下,Kagome蜂窝结构的面内能量吸收性能优于其它3种蜂窝结构,并发现了Kagome蜂窝压缩变形时所特有的局部蜂窝旋转变形. 研究结果表明改变蜂窝形状和周期性排布会对蜂窝结构整体的变形模式以及能量吸收性能产生较大的影响.

Mechanical behavior of 2D periodic honeycombs under in plane uniaxial compression .

基于``平板开缝-装配-焊接''工艺制备了以高聚物为基体的Kagome等蜂窝结构,并开展了Kagome, 正三角形和菱形蜂窝结构的面内准静态压缩力学行为实验研究,实验过程中应用CCD图像采集系统和图像相关法对试件进行了全场位移监测. 另外对比传统正六边形蜂窝,采用数值分析技术,模拟了低速冲击下不同蜂窝结构坍塌行为. 实验结果和数值模拟均揭示了在材料用量和结构尺寸完全相同的情况下,Kagome蜂窝结构的面内能量吸收性能优于其它3种蜂窝结构,并发现了Kagome蜂窝压缩变形时所特有的局部蜂窝旋转变形. 研究结果表明改变蜂窝形状和周期性排布会对蜂窝结构整体的变形模式以及能量吸收性能产生较大的影响.

|

| [14] |

Self-similar hierarchical honeycombs .

Hierarchical structures are observed in nature, and can be shown to offer superior efficiency. However, the potential advantages of structural hierarchy are not well understood. We extensively explored a bending-dominated model material (i.e. transversely loaded hexagonal honeycomb) which is susceptible to improvement by simple iterative refinement that replaces each three-edge structural node with a smaller hexagon. Using a blend of analytical and numerical techniques, both elastic and plastic properties were explored over a range of loadings and iteration parameters. A wide variety of specific stiffness and specific strengths (up to fourfold increase) were achieved. The results offer insights into the potential value of iterative structural refinement for creating low-density materials with desired properties and function.

|

| [15] |

On hierarchical honeycombs under out-of-plane crushing . |

| [16] |

Crushing analysis of metal honeycombs .

A method for determining the crushing strength of hexagonal cell structures subjected to axial loading is given. The method is based on energy considerations in conjunction with a minimum principle in plasticity. The problem is shown to be equivalent to the analysis of a system of collapsing angle elements undergoing bending and extensional deformations. The theory is first developed for an arbitrary angle between panels and then is specified for the 120掳 angle, appropriate for the hexagonal cell structures. Simple formulas are derived relating the crushing force and the wavelength of the local folding wave to the wall thickness and diameter of the cell. The theoretical solution has been compared with experimental results published in the literature and an excellent correlation has been obtained for the wide range of geometrical parameters involved. This solution replaces the less accurate earlier analysis of the same problem due to McFarland. The purpose of this study was to provide a simple and rational means by which hexagonal cell structures can be designed for use as energy absorbers in impact or impulsive loading situations.

|

| [17] |

金属蜂窝材料的弹塑性屈曲临界应力值 .

本文参考Hexcel公司生产的各种规格的金属蜂窝芯,讨论了金属蜂窝芯夹层板承受单轴面外压力时的屈曲模式,发现大多数商用金属蜂窝夹层板受到面外压力作用时发生弹塑性屈曲。基于二维蜂窝结构的代表性单元,建立了金属蜂窝材料弹塑性屈曲的力学模型,进而推导出其临界应力显式公式。该公式反映了蜂窝材料的几何特征及其母材的力学性能,并通过单参数表征金属蜂窝材料的弹塑性屈曲特性。本文还探讨了相对密度和开度角对金属蜂窝材料弹塑性屈曲值的影响规律。最后,通过与已有理论结果和实验结果的比较证实:本文采用的屈曲模式合理,与实验测定值符合较好表明理论预测公式有一定应用价值。

Elasto-plastic buckling critical stress of metal honeycomb .

本文参考Hexcel公司生产的各种规格的金属蜂窝芯,讨论了金属蜂窝芯夹层板承受单轴面外压力时的屈曲模式,发现大多数商用金属蜂窝夹层板受到面外压力作用时发生弹塑性屈曲。基于二维蜂窝结构的代表性单元,建立了金属蜂窝材料弹塑性屈曲的力学模型,进而推导出其临界应力显式公式。该公式反映了蜂窝材料的几何特征及其母材的力学性能,并通过单参数表征金属蜂窝材料的弹塑性屈曲特性。本文还探讨了相对密度和开度角对金属蜂窝材料弹塑性屈曲值的影响规律。最后,通过与已有理论结果和实验结果的比较证实:本文采用的屈曲模式合理,与实验测定值符合较好表明理论预测公式有一定应用价值。

|

| [18] |

金属蜂窝异面压缩下平均压缩应力的理论模型 .

为了得出蜂窝材料在静态压缩及冲击加载下的异面压缩力学行为,基 于蜂窝材料的对称性特点,以Y形蜂窝胞元为研究对象,根据能量守恒原理,将Y形蜂窝胞元所吸收的能量等效为塑性铰转动所需要的能量与Y形蜂窝胞元壁转动所 需要的能量之和,在此基础上,分别采用Mises屈服准则和Tresca屈服准则推导蜂窝材料在静态压缩下的平均压缩应力的理论模型.基于Cowper- Symonds模型考虑应变率对Y形蜂窝胞元材料力学性能的影响,推导蜂窝材料动态平均压缩应力的理论模型.通过一系列的试验,验证了基于Tresca屈 服准则推导的蜂窝材料在异面压缩下的平均压缩应力理论模型的正确性.

Average compressive stress constitutive equation of honeycomb metal under out-of-plane .

为了得出蜂窝材料在静态压缩及冲击加载下的异面压缩力学行为,基 于蜂窝材料的对称性特点,以Y形蜂窝胞元为研究对象,根据能量守恒原理,将Y形蜂窝胞元所吸收的能量等效为塑性铰转动所需要的能量与Y形蜂窝胞元壁转动所 需要的能量之和,在此基础上,分别采用Mises屈服准则和Tresca屈服准则推导蜂窝材料在静态压缩下的平均压缩应力的理论模型.基于Cowper- Symonds模型考虑应变率对Y形蜂窝胞元材料力学性能的影响,推导蜂窝材料动态平均压缩应力的理论模型.通过一系列的试验,验证了基于Tresca屈 服准则推导的蜂窝材料在异面压缩下的平均压缩应力理论模型的正确性.

|

| [19] |

六边形蜂窝等效面外剪切模量预测及其尺寸效应 .

给出了预测六边形蜂窝材料等效剪切模量及其尺寸效应的圆筒扭转力学模型和扭转能量法,建立了等效面外剪切模量<i>G</i><sub>13</sub>相对于材料体分比<i>ν</i>、周向单胞数<i>n</i>、圆筒半径<i>r</i>和单胞层数参数<i>m</i>变化的解析表达式;同时将扭转能量法、有限元数值模拟计算和G-A经典细观力学方法进行了比较,从理论上揭示并验证了尺寸效应的存在性. 结果表明,当蜂窝体胞尺寸相对结构尺寸无穷小时,预测结果趋近于细观力学方法的结果. 此外,利用周期性蜂窝材料的结构对称特性,使用体胞子结构有限元计算模型进行等效面外剪切模量及其尺寸效应的预测,在不影响计算结果的前提下极大地提高了计算效率.

Predictions of effective out-plane shear modulus and size effect of hexagonal honeycomb .

给出了预测六边形蜂窝材料等效剪切模量及其尺寸效应的圆筒扭转力学模型和扭转能量法,建立了等效面外剪切模量<i>G</i><sub>13</sub>相对于材料体分比<i>ν</i>、周向单胞数<i>n</i>、圆筒半径<i>r</i>和单胞层数参数<i>m</i>变化的解析表达式;同时将扭转能量法、有限元数值模拟计算和G-A经典细观力学方法进行了比较,从理论上揭示并验证了尺寸效应的存在性. 结果表明,当蜂窝体胞尺寸相对结构尺寸无穷小时,预测结果趋近于细观力学方法的结果. 此外,利用周期性蜂窝材料的结构对称特性,使用体胞子结构有限元计算模型进行等效面外剪切模量及其尺寸效应的预测,在不影响计算结果的前提下极大地提高了计算效率.

|

| [20] |

Axial crush of metallic honeycombs .

Experimental results for six types of honeycomb cellular structures under quasi-static and impact loads applied in the axial direction are reported. The specimens under both loading conditions were all back-supported with a steel block and were loaded by blunt impactors whose cross-sectional areas were larger than those of the specimens. In the impact test, the velocity history during impact was recorded by the developed laser-Doppler anemometer (LDA), and was subsequently transformed into force and the displacement histories. Both the quasi-static and the impact results showed a load plateau carried by small oscillations when the specimens started to buckle progressively. However, an increase of up to 74% of the crush strength was observed when the specimens which were loaded dynamically were compared with those loaded under the quasi-static conditions, and the increase was found to be proportional to the initial striking velocity of the projectile. For preservation of better energy-absorbing capability per areal density, use of a honeycomb structure with a smaller cell size and core height, and made of a stronger material is suggested. On the other hand, the previously published theoretical model and the manufacture rdata both underestimated the crush strength significantly.

|

| [21] |

Finite element analysis of the dynamic of the aluminum honeycomb .

In this paper, a finite element model was built using ANSYS/LS-DYNA to study the effect of strain rate on the dynamic out-of-plane plateau stress of aluminum honeycombs under constant velocity impact. The strain rates vary from 102 to 104 s-1. It has been found that the t/l ratio (wall thickness to edge length ratio) and strain rate have great influence on deformation pattern and plateau stress. The effect of strain rate on the plateau stress under high velocity impact was found to be different from that under low strain rate compression. The threshold impact velocity is approximately 100 m/s for the aluminum honeycomb studied.

|

| [22] |

High-speed axial impact of aluminum honeycomb --Experiments and simulations .

This paper presents some significant research results about velocity sensitivity of aluminum honeycomb under high-speed axial impact in a velocity range from 20 to 80m/s. Series experiments were carried out with the help of self-developed high-speed impact system. Afterwards, corresponding numerical simulation works as well as some parametric studies were conducted. The resultant comparison told out that the plateau stress increases markedly when impact below 30m/s, but slowly when impact at a velocity various from 30 to 80m/s. Before the parametric studies, inertial effect in various impact masses was investigated. Comparison between parametric results showed that the promotion on Specific Load and energy-absorbing capability increases with the impact velocity for various honeycombs. Density also has a great influence on Specific Load. The higher honeycomb density is, the greater amplitude performs. The energy absorption diagram for honeycomb with different geometric configurations reveals the relationship between dynamic plane stress and energy per unit volume, and also proves the promotion with increasing of impact velocity.

|

| [23] |

Mean out-of-plane dynamic plateau stresses of hexagonal honeycomb cores under impact loadings .

Double-walled hexagonal honeycomb cores (DHHCs) are important cushioning materials and their out-of-plane impact properties depend upon their configuration parameters and impact velocities. In this paper, the reliable finite element (FE) model by using ANSYS/LS-DYNA was designed to investigate the relations between configuration parameters of DHHCs and their out-of-plane dynamic plateau stresses at the impact velocities from 3 to 350聽m/s. FE simulations demonstrate, when all configuration parameters are kept constant, mean out-of-plane dynamic plateau stresses are related to impact velocities by conic curves. For a given impact velocity, mean out-of-plane dynamic plateau stresses are related to the ratios between cell wall thickness and edge length and to edge length ratios by power laws. There are complicated relations between mean out-of-plane dynamic plateau stresses and expanding angels, which are discussed in detail. Many empirical expressions on mean out-of-plane dynamic plateau stresses of DHHCs are suggested.

|

| [24] |

Strain rate effect on the out-of-plane dynamic compressive behavior of metallic honeycombs: Experiment and theory .

Many studies reveal that the dynamic compressive strength of metallic honeycombs is higher than the quasi-static one, but the reasons for that are still debatable. This paper aims to study the strain rate effect of parent materials on the out-of-plane dynamic compressive behavior of metallic honeycombs. Quasi-static and dynamic tests on aluminum honeycombs were performed with universal testing machine and Split Hopkinson Pressure Bar, respectively. The velocity values of dynamic tests were from about 6 to 19m/s. The present and existing measures of plateau stress are evaluated by both the rate-independent (R-I) and rate-dependent (R-D) shock theories. It is shown that the R-D shock theory proposed in our previous study provides more accurate predictions at low, medium and high impact velocities. Based on the R-D shock theory, the influences of strain rate effect are analyzed quantitatively and the change tendencies of measured plateau stresses with impact velocities are explained reasonably. The analysis indicates that the strain rate effect has a large contribution to the dynamic enhancement of metallic honeycombs in a wide velocity range.

|

| [25] |

Strain rate effect on mechanical behavior of metallic honeycombs under out-of-plane dynamic compression .

Abstract Although many researches on the dynamic behavior of honeycombs have been reported, the strain rate effect of parent materials was frequently neglected, giving rise to the underestimated plateau stress and energy absorption (EA). In this paper, the strain rate effect of parent materials on the out-of-plane dynamic compression and EA of metallic honeycombs is evaluated by both numerical simulation and theoretical analysis. The numerical results show that the plateau stress and the EA increase significantly if the strain rate effect is considered. To account for the strain rate effect, a new theoretical model to evaluate the dynamic compressive plateau stress of metallic honeycombs is proposed by introducing the Cowper-Symonds relation into the shock theory. Predictions of the present model agree fairly well with the numerical results and existing experimental data. Based on the present model, the plateau stress is divided into three terms, namely static term, strain rate term, and inertia term, and thus the influences of each term can be analyzed quantitatively. According to the analysis, strain rate effect is much more important than inertia effect over a very wide range of impact velocity.

|

| [26] |

Analytical solutions for heat transfer efficiency in metallic honeycombs using two-equation method . |

| [27] |

低速冲击下金属蜂窝夹芯板抗侵彻性能的试验研究 .

利用落锤冲击试验系统,研究了金属蜂窝夹芯板在低速冲击载荷作用下的抗侵彻行为。试验获得了平头、半球形和锥形锤头冲击下蜂窝夹芯板的破坏模式和力-位移曲线,分析了锤头形状和芯材厚度对夹芯板最终破坏模式、力-位移曲线和临界破坏能量的影响。试验结果表明:夹芯板在平头、半球形和锥形锤头冲击下上面板分别产生了圆形剪切、圆形拉伸和钻石形的最终失效模式,下面板的最终失效模式分别为圆形剪切、瓣形开裂和瓣形开裂;金属蜂窝夹芯薄板在锥形锤头和半球形锤头冲击下的力-位移曲线会出现单峰模式,金属蜂窝夹芯厚板在锥形锤头和半球形锤头冲击下的力-位移曲线则是双峰模式,而在平头锤头冲击下的金属蜂窝夹芯板的力-位移曲线均为双峰模式;金属蜂窝夹芯薄板抵抗半球形锤头侵彻的能力最好,抵抗平头锤头侵彻的能力最差,而金属蜂窝夹芯厚板抵抗锥形锤头侵彻的能力最好,抵抗平头锤头和半球形锤头侵彻的能力较差。

Experiment investigation on against penetration of metallic honeycomb sandwich plates under low-velocity impact .

利用落锤冲击试验系统,研究了金属蜂窝夹芯板在低速冲击载荷作用下的抗侵彻行为。试验获得了平头、半球形和锥形锤头冲击下蜂窝夹芯板的破坏模式和力-位移曲线,分析了锤头形状和芯材厚度对夹芯板最终破坏模式、力-位移曲线和临界破坏能量的影响。试验结果表明:夹芯板在平头、半球形和锥形锤头冲击下上面板分别产生了圆形剪切、圆形拉伸和钻石形的最终失效模式,下面板的最终失效模式分别为圆形剪切、瓣形开裂和瓣形开裂;金属蜂窝夹芯薄板在锥形锤头和半球形锤头冲击下的力-位移曲线会出现单峰模式,金属蜂窝夹芯厚板在锥形锤头和半球形锤头冲击下的力-位移曲线则是双峰模式,而在平头锤头冲击下的金属蜂窝夹芯板的力-位移曲线均为双峰模式;金属蜂窝夹芯薄板抵抗半球形锤头侵彻的能力最好,抵抗平头锤头侵彻的能力最差,而金属蜂窝夹芯厚板抵抗锥形锤头侵彻的能力最好,抵抗平头锤头和半球形锤头侵彻的能力较差。

|

| [28] |

蜂窝夹芯板与Whipple结构对撞击能量吸收与耗散的特性比较 .

通过数值仿真模拟弹丸高速撞击蜂窝夹芯板和Whipple结构,研究蜂窝芯对弹丸碎片云形态的影响;并研究了弹丸、蜂窝夹芯板、Whipple结构的能量吸收与耗散。结果表明:弹丸撞击蜂窝夹芯板后碎片云形态呈近似椭球体,且长半轴明显较长,而弹丸撞击Whipple结构的碎片云形态呈近似球体;蜂窝芯吸收的能量随弹丸的破碎程度的增强而增加;弹丸能量衰减主要发生在撞击蜂窝夹芯板的前后面板和Whipple结构的两层板,蜂窝芯的吸能作用使得Whipple结构吸收的能量高于蜂窝夹心板面板吸收的能量。

Characteristic comparison of energy absorbing and dissipating of honeycomb panel and Whipple structure in hypervelocity impact .

通过数值仿真模拟弹丸高速撞击蜂窝夹芯板和Whipple结构,研究蜂窝芯对弹丸碎片云形态的影响;并研究了弹丸、蜂窝夹芯板、Whipple结构的能量吸收与耗散。结果表明:弹丸撞击蜂窝夹芯板后碎片云形态呈近似椭球体,且长半轴明显较长,而弹丸撞击Whipple结构的碎片云形态呈近似球体;蜂窝芯吸收的能量随弹丸的破碎程度的增强而增加;弹丸能量衰减主要发生在撞击蜂窝夹芯板的前后面板和Whipple结构的两层板,蜂窝芯的吸能作用使得Whipple结构吸收的能量高于蜂窝夹心板面板吸收的能量。

|

| [29] |

|

| [30] |

Perforated core honeycomb panel system . US Patent: |

| [31] |

Compressive crushing of novel aluminum hexagonal honeycombs with perforations: experimental and numerical investigations .

The quasi-static compressive behavior of novel aluminum hexagonal honeycombs with perforations on the cell wall is investigated experimentally and numerically. Compressive experiments on the perforated honeycombs with different cell numbers are conducted to study the effect of specimen sizes. The measured collapse stress is almost insensitive to the specimen sizes, while the crushing stress increases with the cell numbers and finally converges to a stable plateau for the specimens beyond 1562×6215 cells. Finite element simulations are performed to study the effects of perforation size, spacing and shape on the mechanical properties of honeycombs. The results reveal that perforation size is a key parameter that affects the compressive mechanical properties and deformation patterns of honeycombs. The perforation number along the height direction of a cell has nearly no influence on the collapse stress, and only affect the crushing stress when the perforation size is large. The perforation shape impacts the collapse of honeycombs but has minor effect on the subsequent crushing stage.

|

| [32] |

Quasi-static crush behavior of aluminum hexagonal honeycomb with perforated cell walls .

The crush behavior of aluminum hexagonal honeycomb with perforated cell walls under out-of-plane quasi-static loadings was experimentally investigated. The honeycomb specimens with different heights were compressed in axial direction under displacement control. There are four sequential deformation stages during compression: linear elasticity, buckling, crushing and densification state. The performances of hexagonal honeycombs with perforated cell walls were compared with those of imperforated hexagonal honeycombs with the same sizes. The results show that the perforated holes weaken the strength of honeycombs markedly and the strength of honeycomb decreases with the specimen height.

|

| [33] |

Inertia effects in uniaxial dynamic compression of a closed cell aluminium alloy foam .

The dynamic compressive characteristics of a closed cell aluminium alloy foam (manufactured by Hydro Aluminium AS, Norway) have been studied experimentally by using a direct impact technique for a range of velocities up to 210 m s0900091. Experimental data on the dynamic initial crushing and plateau stresses are compared for two average cell sizes of approximately 4 and 14 mm. The data reveal significant dynamic enhancements of the initial crushing strengths throughout the range of velocities used. The dynamic plateau stresses are insensitive to impact velocity below the values of 50 and 100 m s0900091 for the large and small cell foams respectively. Beyond a critical velocity value of ~ 100 m s0900091, the crushing wave front propagates through the foam with shock like characteristics. The inertia effects associated with the dynamic localisation of crushing and the microinertia of the cell wall/edge material on the dynamic strength enhancement are discussed. A one-dimensional shock model based on a rate independent, rigid, perfectly plastic locking idealisation of the nominal stress090009strain curve for foams is employed to provide a first order understanding of the various parameters involved in the crushing process. The results of the analyses are seen to predict well the dynamic strength enhancements that are measured experimentally. The sources of discrepancies are highlighted and discussed, as are the limitations and shortcomings of the shock model.

|

/

| 〈 |

|

〉 |