一种考虑非比例附加损伤的多轴低周疲劳模型1)

湖南大学汽车车身先进设计制造国家重点实验室,长沙 410082

A MULTIAXIAL LOW-CYCLE FATIGUE MODEL CONSIDERING NON-PROPORTIONAL ADDITIONAL DAMAGE1)

中图分类号: TG111.8

文献标识码: A

通讯作者:

收稿日期: 2018-10-19

网络出版日期: 2019-05-18

版权声明: 2019 力学学报期刊社 所有

基金资助:

展开

摘要

在实际工作环境中,机械结构往往承受着多轴非比例循环载荷.相比多轴比例循环加载,多轴非比例循环加载由于产生了附加强化现象,造成机械结构疲劳寿命下降.通过分析薄壁圆筒管件在非比例加载工况下应力应变变化规律和发生破坏位置,本文基于临界面法提出一种考虑多轴非比例附加损伤的疲劳模型.该模型将最大剪切应变幅平面作为临界面,提出一个新的附加强化因子,结合临界面上切应变幅和正应变幅组成新的多轴疲劳损伤参量.此参量不仅考虑了非比例加载下临界面上正应变幅和切应变幅对材料造成的疲劳损伤,还考虑到应变路径的变化和材料非比例加载敏感特性对材料疲劳寿命的影响.考虑到实际情况下模型所需材料附加强化系数有时难以获得的情况,给出了材料附加强化系数的有关近似计算公式.只需要材料基本力学参数便可得到材料附加强化系数,方便工程实际应用.采用8种材料的多轴疲劳寿命数据对提出的新模型进行检验,结果表明所提出的新模型与传统多轴疲劳模型相比预测寿命精度更高.

关键词:

Abstract

In the actual working environment, the mechanical structure is often subjected to multi-axial non-proportional cyclic load. Compared with the multiaxial proportional cyclic load, the multiaxial non-proportional cyclic load has an additional strengthening phenomenon, resulting in a decrease in the fatigue life of the mechanical structure. With the analysis of the stress and strain variation and the failure location of thin-walled cylindrical specimen under non-proportional loading conditions, a new low cycle multiaxial fatigue life prediction model considering multiaxial non-proportional additional damage is proposed based on the critical plane approach. The new low cycle multiaxial fatigue life prediction model takes the maximum shear strain plane as the critical plane, and proposes a new additional strengthening factor, which combines the shear strain amplitude and the normal strain amplitude on the critical surface to form a new low cycle multiaxial fatigue damage parameter. This new low cycle multiaxial fatigue damage parameter not only considers the fatigue damage caused by the positive strain amplitude and the shear strain amplitude on the critical surface under non-proportional loading, but also considers the influence of the strain path change and the non-proportional loading sensitivity of the material on the fatigue life of the material. Considering the fact that the additional strengthening coefficient of the material required by the model is sometimes difficult to obtain, the approximate calculation formulas of the additional strengthing coefficient of the material is given. Only the basic mechanical parameters of the material can be used to obtain additional strengthening coefficient of the material, which is convenient for practical application of the project. The fatigue life data of eight materials were used to test the new low cycle multiaxial fatigue life prediction model. The results show that the new low cycle multiaxial fatigue life prediction model has higher life prediction accuracy than the traditional multiaxial fatigue life prediction model.

Keywords:

引 言

大多数机械结构在实际工作中承受着循环载荷,因此研究机械结构在循环载荷下失效机理有十分重要的实际意义.这其中单轴循环载荷下结构的疲劳寿命预测理论已经十分成熟,广泛应用于各种实际工程设计中.但是由于结构的几何形状的复杂性以及所承受的载荷往往为非比例循环加载,结构实际失效类型通常为多轴疲劳失效,采用单轴疲劳寿命预测理论进行预测结果往往相差很大.因此研究机械构件在多轴载荷下的失效情况具有重要的工程应用价值[1-3].当构件在承受多轴非比例载荷时,由于非比例附加强化效应的影响,相同等效应变下,承受多轴疲劳载荷作用的构件寿命通常比承受单轴载荷的构件寿命低.这是因为结构在承受多轴非比例载荷时,应变和应力主轴不断旋转,引起多滑移系的开动,使得材料产生附加阻力抵抗变形.在宏观上表现出来材料有明显的附加强化现象.已有研究表明这种附加强化与载荷间的相位差和材料本身对非比例路径的敏感程度有关[4].

到目前为止,有关多轴疲劳寿命预测的各类方法研究可大致分为三类,分别是等效应变法,能量法,临界面法.相比前两种方法的不足,临界面法物理意义明确且预测精度高,受到了国内外学者的广泛关注.基于临界面法,众多学者提出了各自的多轴疲劳寿命模型.Brown等[5]最早提出了基于临界面概念的多轴低周疲劳模型,以最大切应变面作为临界面,将临界面上正应变和切应变作为多轴疲劳参量.Kandil等[6]利用最大剪切应变幅和最大剪切应变幅平面上的法向正应变进行线性组合提出了KBM模型.Fatemi等[7]在研究KBM模型时发现仅靠应变不能体现材料因非比例附加强化现象导致的寿命下降,通过引入临界面上正应力来反映材料附加强化现象,提出了FS模型.Pitatzis等[8]基于能量临界面法提出一种能适应多轴加载的疲劳寿命预测模型.Li等[9]考虑到材料在非比例路径下附加强化效应,基于KBM模型提出了MKBM模型.赵而年等[10]在研究了材料在非比例加载下路径因子和材料附加强化参数的关系后,发现FS模型不能很好预测某些附加强化参数为零的材料疲劳寿命,提出了基于FS模型的修正FS模型.周昊等[11]针对焊接结构的多轴疲劳失效机理,提出了一种基于临界面法的多轴疲劳准则.上述研究证明了临界面法能较好地预测多轴疲劳寿命.但是,由于材料的使用环境不同和所承受载荷的复杂性,并没有一种多轴疲劳临界面模型能够适用于各种金属材料.想要建立统一的多轴疲劳寿命预测模型,还需深入研究多轴疲劳机理才能建立起通用的多轴疲劳寿命预测模型[12-13].

本文综合考虑路径非比例和材料附加强化现象对材料疲劳寿命的影响,通过给出材料附加强化系数的近似计算公式,提出了一个新的非比例附加强化因子,并将该附加强化因子与临界面上切应变幅和正应变幅进行组合,构造出新的多轴疲劳损伤参量,结合Manson-Coffin公式建立新的多轴疲劳寿命预测公式.对8种材料进行疲劳寿命预测并和FS模型进行对比分析,结果表明本文所提出的新模型预测精度更高.

1 拉扭载荷下薄壁管应变分析

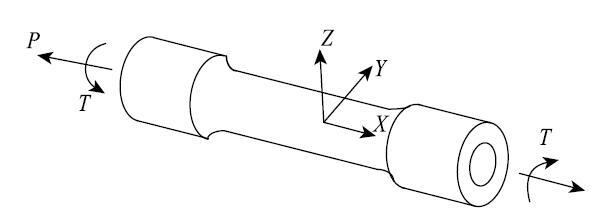

如图1,作为简单的几何构件,薄壁管可以通过拉、扭、内压、外压等载荷来获得需要的应变状态.并且在进入塑性范围后能对薄壁管进行准确的应变分析,能够满足多轴疲劳试验分析的要求.

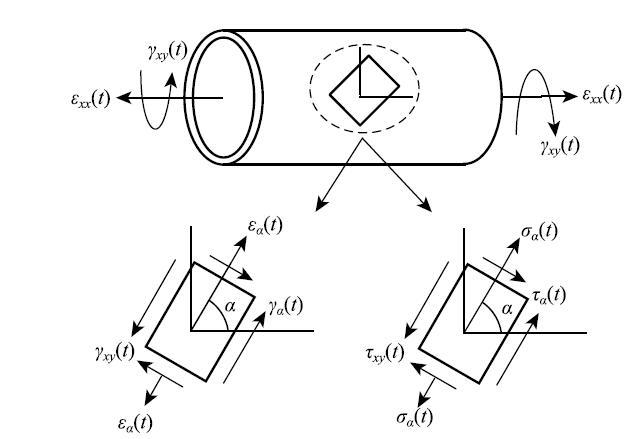

当薄壁管试件承受拉扭应变载荷时,试件薄壁处应力状态可以视为平面应力状态,如图2所示,任意时刻$t$下应变状态可以表示为

\begin{equation} \label{eq1} \varepsilon=\left[ {{\begin{array}{*{20}c} {\varepsilon _{xx} (t)} & {\dfrac{1}{2}\gamma _{xy} (t)} & 0 \\ {\dfrac{1}{2}\gamma _{xy} (t)} & {\nu _{\rm eff} \varepsilon _{xx} (t)} & 0 \\ 0 & 0 & {\nu _{\rm eff} \varepsilon _{xx} (t)} \\ \end{array} }} \right]\tag{1} \end{equation}

式中,$\varepsilon _{xx} \left( t \right)$为轴向应变,$\gamma_{xy} \left( t \right)$为切向应变,$\nu _{\rm eff} $为等效泊松比

\begin{equation} \label{eq2} \nu _{\rm eff} = \frac{\nu _{\rm e} \Delta \varepsilon _{\rm e} + \nu _{\rm p} \Delta \varepsilon _{\rm p} }{\Delta \varepsilon _{\rm e} + \Delta \varepsilon _{\rm p} }\tag{2} \end{equation}

式中,$\nu _{\rm e} $为弹性泊松比,$\nu _{\rm p}$为塑性泊松比$\Delta \varepsilon _{\rm e} $为弹性应变范围,$\Delta\varepsilon _{\rm p} $为塑性应变范围.

图2 拉扭状态下试件的应力应变状态

Fig. 2 Stress-strain state of the test piece under tension and twist

与薄壁管件轴向方向成$\alpha $角度的法向应变$\varepsilon _\alpha\left( t \right)$与切向应变$\gamma _\alpha \left( t \right)$分别为

$$ \varepsilon _\alpha ( t ) = \frac{{\rm 1 - }\nu _{{\rm eff}} }{2}\varepsilon _{xx} ( t ) + \frac{1 + \nu _{\rm eff} }{2} {\varepsilon _{xx} ( t )} \cos 2\alpha + \\ \frac{1}{2} {\gamma _{xy} ( t )} \sin 2\alpha \tag3$$

$$\gamma _\alpha ( t ) = {\rm - }(1 + \nu _{\rm eff} ) {\varepsilon _{xx} ( t )} \sin 2\alpha + {\gamma _{xy}( t )}\cos 2\alpha\tag4 $$

1.1 正弦波加载下临界面确定方法

正弦波加载下,轴向应变与切向应变表示为

$${\varepsilon _{{{xx}}}}(t) = {\varepsilon _a}\sin \left( {\omega {\rm{t}}} \right) + {\varepsilon _{\rm m}}\tag5 $$

$$ \label{eq6} \gamma _{{xy}} \left( t \right) = \gamma _a \sin (\omega t - \varphi ) + \gamma _{\rm m}\tag6$$

$$\label{eq7} \lambda = \frac{\gamma _a }{\varepsilon _a }\tag7$$

式中, $\varepsilon _a $为轴向应变幅,$\varepsilon _{\rm m}$为平均轴向应变,$\gamma _a $为切向应变幅,$\gamma _{\rm m}$为平均切向应变,$\varphi $为相位角,$\lambda $为应变比.

通过数学推导,可得到于轴线角度成任意$\alpha$角平面上的法向应变幅值${\Delta \varepsilon _\alpha }/2$和切向应变幅值${\Delta \gamma_\alpha } /2$

$$\frac{\Delta \varepsilon _\alpha }{2} = \frac{1}{2}{[2(1 + \nu _{\rm eff} )\cos ^2\theta - 2\nu _{\rm eff} + \lambda \sin 2\theta \cos \delta ]^2 + [\lambda \sin 2\theta \sin \delta ]^2}^{1 / 2} \tag8 $$

$$\frac{{\Delta {\gamma _\alpha }}}{2} = {\varepsilon _a}\{ {[\lambda \cos 2\alpha \cos \delta - (1 + {v_{\rm eff}})\sin 2\alpha ]^2}{\rm{ + }} {\rm{ }}{(\lambda \cos 2\alpha \sin \delta )^2}{\} ^{1/2}} \tag9 $$

假设最大剪切应变平面与轴向角度为$\alpha _{{\rm max}}$,则满足以下关系式

\begin{equation}\label{eq9} {\rm tan}4\alpha _{\max } = \frac{2\lambda (1 + \nu_{\rm eff} )\cos \varphi }{\left( {1 + \nu _{\rm eff} } \right)^2-\lambda ^2}\tag{10}\end{equation}

注意到$\alpha $取值范围在$\left[ {{\rm - 90}^{\circ}~~ 90^{\circ}} \right]$之间,在这个区间内满足上式的$\alpha _{{\rm max}} $有4个,将这4个值代入式(9)中,找到两个最大切应变幅值,将这两个值代入式(8)中,找到最大正应变幅值, 这样就确定了拉扭加载下薄壁管件在最大剪切应变平面上的法向应变幅${\Delta \varepsilon _{\alpha ,\max } } / 2$和切向应变幅${\Delta \gamma _{\alpha ,\max } }/2$. 以上公式也适用于三角波加载.

1.2 一般加载情况临界面确定方法

对于一般加载情况,采用数值解法来获得任意平面上应变关系,取其中最大切应变平面作为临界面.具体步骤如下:

(1)获得在一般加载路径下应变响应$\varepsilon \left( t \right)$,$\gamma \left( t \right)$.

(2)由式(3)和式(4)可以得到与试件轴线方向成$\alpha$角度的法向应变$\varepsilon _\alpha \left( t\right)$与切向应变$\gamma _\alpha \left( t \right)$.

(3)确定与试件轴线成$\alpha$角度下试件平面的最大与最小应变$\varepsilon _{\alpha ,\max }$,$\varepsilon _{\alpha ,\min }$,$\gamma _{\alpha ,\max }$,$\gamma _{\alpha ,\min }$.

(4)确定$\alpha $角度下试件平面正应变幅与切应变幅${\Delta\varepsilon _\alpha }/2$,${\Delta \gamma _\alpha }/2$,并确定最大切应变幅所在平面,计算公式如下

$$\frac{\Delta \varepsilon _\alpha }{2} = \frac{\varepsilon_{\alpha ,\max } -\varepsilon _{\alpha ,\min } }{2}\tag11$$

$$\frac{\Delta \gamma _\alpha }{2} = \frac{\gamma _{\alpha ,\max }-\gamma _{\alpha ,\min } }{2}\tag12$$

(5)取步长为0.1$^\circ$,角度$\alpha$从$-$90$^\circ$增大到90$^\circ$,找出最大切应变幅所在平面$\alpha_{\max \gamma }$,若有多个最大切应变幅所在平面,取其中最大正应变幅所在平面$\alpha_{\max } $,这样便确定出临界面和该平面上切应变幅${\Delta \gamma_{\alpha ,\max } }/2$和正应变幅${\Delta \varepsilon _{\alpha ,\max } }/2$.

2 非比例多轴加载下影响寿命因素

许多试验结果已经证实了在相同等效应变下,非比例加载下材料的疲劳寿命短于比例加载下材料的疲劳寿命.这是由于在非比例路径加载下,材料不能形成稳定的位错结构,产生了抵抗材料发生变形的附加阻力.宏观表现为材料发生非比例附加强化效应,在相同等效应变下非比例加载的应力相应值较比例加载的应力相应值要大,导致材料的疲劳寿命下降.但是赵而年等[10]注意到某些金属材料在非比例载荷作用下并没有发生附加强化现象,寿命却比材料在相同等效应变下的比例载荷寿命低.因此还需考虑到非比例加载路径对材料疲劳寿命的影响.合理预测材料的疲劳寿命,需要综合考虑载荷路径和材料非比例载荷敏感程度对疲劳寿命影响.本文通过分析材料在非比例加载下相关物理现象,给出了有关路径非比例度和材料附加强化的度量方法,结合两者定义了一个新的多轴非比例影响因子.

2.1 路径非比例对疲劳寿命影响

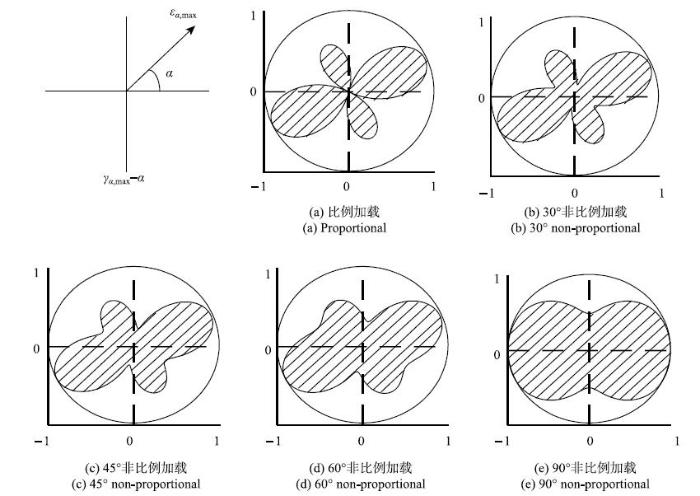

国内外许多学者认为非比例路径对材料的疲劳寿命有直接影响.通过对比相同等效应变下不同应变路径多轴疲劳寿命结果可发现疲劳寿命与应变路径存在一定关联性.Chen等[14]给出了应变比为$\sqrt 3$时不同正弦波加载路径下与轴线成角度$\alpha$的平面上最大切应变$\gamma _{\alpha ,{\rm max}} $的值.

从图3可以发现,比例加载下$\gamma _{\alpha ,\max } - \alpha$所围成的图形面积最小,随着相位差增大,$\gamma _{\alpha ,\max } -\alpha $面积也增大,当相位差为$90^{\circ}$时达到最大.通过研究多轴疲劳寿命数据发现,在相同等效应变加载下,材料的疲劳寿命随着相位差的增大而下降.

图3 不同应变路径下$\gamma _{\alpha ,\max } - \alpha $图形

Fig. 3 $\gamma _{\alpha ,\max } - \alpha$ graphics under different strain paths

Itoh等[15]认为在不同加载路径下主应变方向变化和主应变大小的变化同样对多轴低周疲劳寿命有很大影响.如图4所示,绘制出应变比为$\sqrt 3$时不同正弦波加载路径下与轴线成任意角度$\alpha$平面上主应变$\varepsilon _{\alpha ,\max } $的值.

图4 不同应变路径下$\varepsilon _{\alpha ,\max } {\rm - }\theta $图形

Fig. 4 $\varepsilon _{\alpha ,\max } {\rm - }\theta $ graphics under different strain paths

从图4同样可发现,在相同等效应变加载下,随着相位差增大,$\varepsilon_{\alpha ,\max } {\rm - }\theta $所围成图形面积也同样在增大.可以认为$\varepsilon _{\alpha ,\max } $和$\gamma _{\alpha ,{\rm max}} $对材料在不同加载路径下的寿命均有影响,需综合考虑两者的影响.因此,为了反映非比例路径加载对多轴疲劳寿命的影响,定义了一个非比例路径加载影响参数$\phi$

\begin{equation}\label{eq10} \phi = \sqrt {\phi _\varepsilon ^2 + \phi _\gamma ^2+ \phi _\varepsilon \phi _\gamma }\tag{13}\end{equation}

式中,$\phi _\varepsilon $和$\phi _\gamma$分别为非比例加载下切应变和正应变非比例影响参数,定义为

$$\label{eq11} \phi _\varepsilon = \frac{A\varepsilon _\theta -A\varepsilon _{\min } }{A\varepsilon _{\max } }\tag14$$

$$\label{eq12} \phi _\gamma = \frac{A\gamma _\theta - A\gamma_{\min } }{A\gamma _{\max } }\tag15$$

式中,$A\varepsilon _\theta $为极坐标下$\varepsilon _{\alpha ,\max} {\rm - }\theta $在一个循环内围成的面积;$A\varepsilon _{\min }$为极坐标下比例加载时$\varepsilon _{\alpha ,\max } {\rm - }\theta$在一个循环内围成的面积;$A\varepsilon _{\max }$为极坐标下90$^\circ$ 非比例加载时$\gamma _{\alpha ,\max } -\alpha $在一个循环内围成的面积;$A\gamma _\theta$为极坐标下$\gamma _{\alpha ,\max } - \alpha$在一个循环内围成的面积;$A\gamma _{\min }$为极坐标下比例加载时$\gamma _{\alpha ,\max } - \alpha$在一个循环内围成的面积;$A\gamma _{\max } $为极坐标下90$^\circ$非比例加载时$\gamma _{\alpha ,\max } - \alpha$在一个循环内围成的面积.

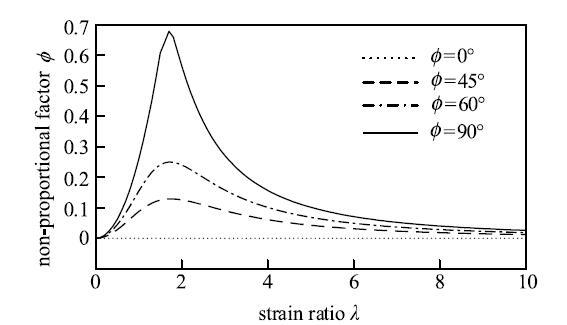

图5给出了不同相位差下本文所定义的非比例路径影响因子$\phi$随应变比变化的变化关系,由图3可以观察到,$\phi$随着应变比$\lambda $增大先增大后减小,当$\lambda = \sqrt {\rm 3}$时$\phi $达到最大值. 相同应变比下,$\phi$随着相位差增大而增大,且当$\lambda = \sqrt {\rm 3}$相位差为90$^\circ$时取得最大值,即此时$\phi$对材料多轴疲劳寿命的下降影响最大,这与实验现象吻合.

图5 不同相位和应变比下非比例路径影响因子的值

Fig. 5 Non-proportional path factor under different phase and strain ratio

2.2 考虑材料附加强化的非比例影响因子

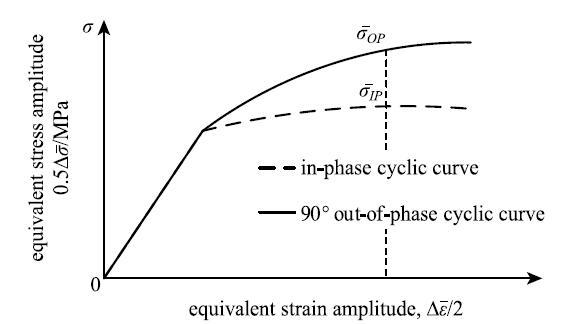

已有的研究表明不同材料对非比例加载路径的敏感程度也不同,这意味着不同材料的疲劳寿命受到非比例加载路径的影响程度也是不一的.从图6可看出,材料的应力应变曲线随加载路径而变化.为了量化材料的附加强化效应,材料的附加强化参数$g$定义为[16]

\begin{equation}\label{eq13} { g} = \frac{\overline \sigma _{OP} }{\overline\sigma _{IP} } - 1\tag{16}\end{equation}

式中,$\overline \sigma _{OP} $和$\overline \sigma _{{IP}}$为进入塑性应变阶段后相同应变条件下加载方式为90$^\circ$圆形非比例加载和比例加载时等效应力.

式(16)给出材料附加强化参数计算公式,然而在实际中难以得到这一参数.如何估算这一参数引起了国内外学者广泛关注. Borodii等[17]认为材料的极限强度和屈服强度之比与材料附加强化有关,并给出了计算公式,姜潮等[18]和陈志超等[19]也提出了类似的计算公式.但是Shamsaei等[20]指出这一方法在预测材料附加强化参数时误差较大,Shamsaei等认为材料的附加强化与材料在单轴循环加载下应力和静态拉伸时应力有关,通过推导给出了以下计算公式

\begin{equation} \label{eq14} {g = 1.6}\left( {\frac{K}{{K}'}} \right)^{\rm 2}\left( {\frac{\Delta \overline \varepsilon }{2}} \right)^{2\left( {n - {n}'} \right)}{\rm - 3.8}\left( {\frac{K}{{K}'}} \right)\left( {\frac{\Delta \overline \varepsilon }{2}} \right)^{\left( {n - {n}'} \right)}{\rm + 2.2}\tag{17} \end{equation}

式中,$K$为硬化系数,${K}'$为循环硬化系数.$n$为硬化指数,${n}'$为循环硬化指数.经实验验证,用式(17)计算得到的材料附加强化参数与试验值重合度较高[17].

从图6可以看出材料的附加强化参数$g$随着等效应变变化而变化,不是一个常数.对于某些材料,硬化指数$n$与循环硬化指数${n}'$相差不大,此时$g$可近似看作只与硬化系数$K$和循环硬化系数${K}'$有关,与材料的其他参数无关.考虑到在实际情况中有时难以获得材料硬化系数等参数,本文查阅有关文献,给出式(17)有关参数的近似公式.

胡志忠等[21]研究了硬化指数$n$与强度之间关系,导出了硬化指数$n$与屈强比之间的关系

\begin{equation}\label{eq15} n = 1 - \sqrt {\frac{\sigma _{\rm y} }{\sigma _{\rm u} }}\tag{18}\end{equation}

式中,$\sigma _{\rm u} $为抗拉强度,$\sigma _{\rm y}$为屈服强度,${\sigma _y }/ {\sigma _{\rm u} }$为屈强比.

孙东继等[22]详细推导了硬化系数$K$与抗拉强度$\sigma _{\rm y}$和硬化指数$n$似关系,给出以下计算公式

\begin{equation}\label{eq16} K = \frac{\sigma _{\rm u} }{\left( {\dfrac{n}{e}}\right)^n}\tag{19}\end{equation}

Lopze等[23]在研究大量材料的循环硬化指数${n}'$和循环硬化系数${K}'$与强度之间的关系后,得出以下公式

当${{\rm }\sigma _{\rm u} }/{\sigma _{\rm y} } > 1.2$时

$$\label{eq17} {K}' = 1.16(\sigma _{\rm u} ) + 593\tag20 $$

$$\label{eq18} {n}' = - 0.37\lg \left( {\frac{0.75\sigma _{\rm y} + 82}{1.16\sigma _{\rm u} + 593}} \right)\tag21$$

当${{\rm }\sigma _{\rm u} }/ {\sigma _{\rm y} } \le 1.2$时

$$\label{eq19} {K}' = 3.0\times 10^{ - 4}\left( {\sigma _{\rm u} } \right)^2 + 0.23\left( {\sigma _{\rm u} } \right) + 619\tag22$$

$$\label{eq20} {n}' = - 0.37\lg \left( {\frac{3.0\times 10^{ - 4}\sigma _{\rm y} ^2 - 0.15\sigma _{\rm y} + 526}{3.0\times 10^{ - 4}\sigma _{\rm u} ^2 + 0.23\sigma _{\rm u} + 619}} \right)\tag{23}$$

利用式(17) $\sim$式(3),只需要材料的$\sigma _{\rm u}$为抗拉强度,$\sigma _{\rm y}$为屈服强度即可计算出材料的附加强化系数,便于实际使用.

综合以上有关路径非比例度和材料附加强化系数的讨论,考虑到两者对于材料疲劳寿命均有影响,本文提出一个非比例附加影响因子

\begin{equation}\label{eq21} \psi = \sqrt {{\rm 1} + \phi (1 + g)}\tag{24}\end{equation}

该非比例附加影响因子基于实际现象提出,充分考虑了材料的非比例附加强化现象和非比例路径对疲劳寿命的影响,并对某些材料没有附加强化现象时仍能反映非比例路径对材料寿命的影响.

3 考虑附加损伤的多轴低周疲劳模型

已有的实验证明了材料的疲劳裂纹通常发生在最大剪切平面上,随后在该平面上法向应变的促进下,沿最大剪切平面进行扩展.多数学者提出的多轴疲劳临界面模型都将临界面上最大切应变和正应变作为材料疲劳寿命的控制参数.为了体现相同等效应变下材料非比例加载下寿命较比例加载下寿命低的情况,一些学者通过引入各自的非比例影响因子来反映材料的附加强化现象$^{[4,10,14\mbox{-}15,18]}$.但是到目前为止,没有一种多轴疲劳模型能准确预测各类金属材料在复杂加载路径下疲劳寿命.本文在详细讨论了影响材料在多轴载荷下疲劳寿命的两个重要因素基础上,以最大切应变平面上切应变幅和正应变幅为第一和第二控制参数,结合所提出非比例附加影响因子,提出一个新的疲劳损伤控制参量

$$\frac{\Delta {\varepsilon }'_{\rm eq} }{2} = \sqrt {\psi \left( {\frac{\left( {{\Delta \gamma _{\alpha ,\max } }/2} \right)^2}{3} + \left( {\frac{\Delta \varepsilon _{\alpha ,\max } }{2}} \right)^2} \right)}\tag{25}$$

$$\label{eq23} \frac{\Delta {\varepsilon }'_{\rm eq} }{2} = \frac{\sigma _{\rm f}' }{E}\left( {2N_{\rm f} } \right)^b + \varepsilon _{\rm f}' \left( {2N_{\rm f} } \right)^c\tag{26} $$

式中,$\sigma _{\rm f}' $为疲劳强度系数,$\varepsilon _{\rm f}'$为疲劳延性系数,$b$为疲劳强度指数,$c$为疲劳延性指数.

新的模型将最大切应变平面作为材料发生疲劳破坏平面,并通过引入前文中所定义的非比例附加影响因子来考虑非比例加载对材料造成的附加损伤.现将该模型称为HC模型.

4 试验验证

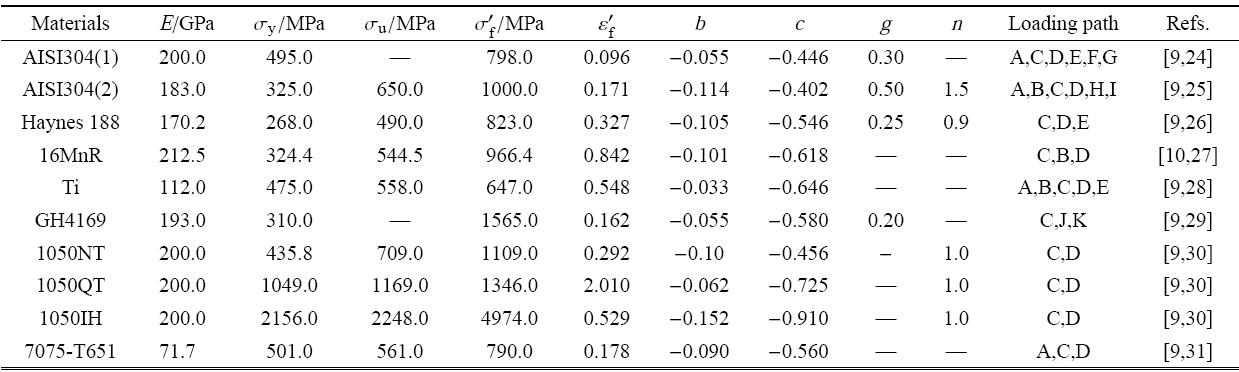

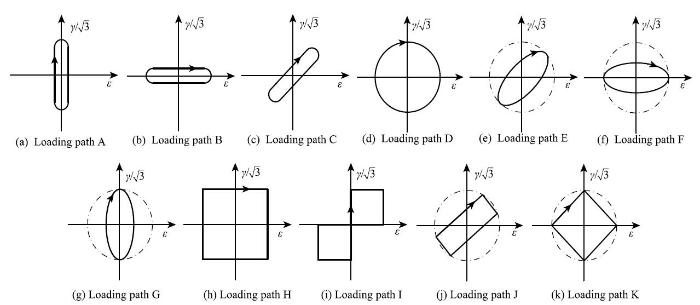

选用表1中材料来验证所提出的HC模型,包括比例加载和非比例加载共计234个数据点.材料的试件均为图1所示薄壁管件,加载方式为图2所示拉扭加载,加载路径见图7.表1中数据从文献[9,24-31]直接获得,对于某些没有给出附加强化系数的材料,通过式(17)$\sim$式(23)计算得到材料的附加强化系数.

Fatemi等[7]在研究材料在多轴载荷下发生疲劳破坏的位置和应力变化规律后认为影响材料疲劳寿命的主要因素是最大切应变幅${\Delta\gamma _{\alpha ,\max } }/2$.考虑到裂纹扩展和材料在多轴载荷下附加强化现象,将临界面上正应力$\sigma_{\max }$作为影响材料疲劳寿命的因素,提出了一个受到广泛关注的疲劳寿命模型(FS模型)\begin{equation}\label{eq24} \frac{\Delta \gamma _{\max } }{2}\left( {1 +n\frac{\sigma _{\max } }{\sigma _{\rm y} }} \right) = f\left({N_{\rm f} } \right)\tag{27}\end{equation}式中,$n$为材料经验系数,难以确定时可取$n$=1.

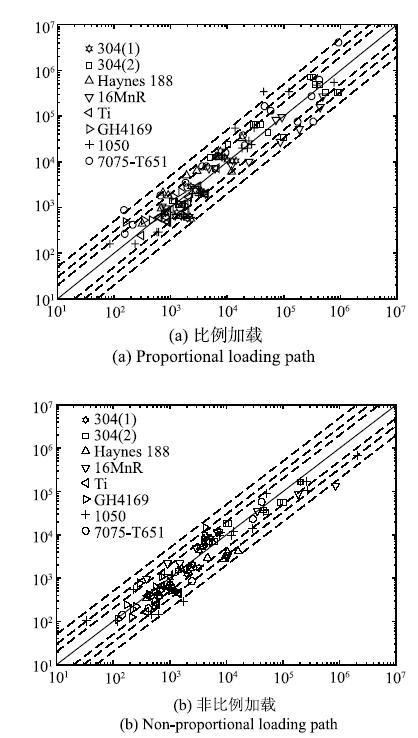

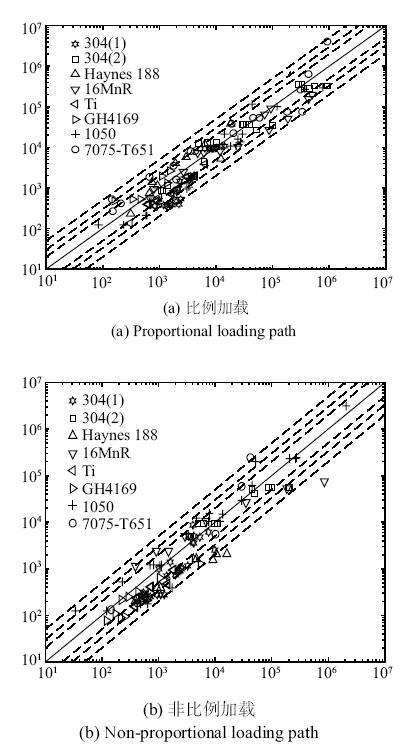

采用FS模型和本文提出的HC模型进行对比,以验证HC模型的正确性和预测精度.图8为HC模型对表1中材料的寿命预测结果,图9为FS模型对表1中材料的寿命预测结果.图中从内向外给出了2倍、3倍和5倍误差带.从图中可以看出在比例加载情况下,FS模型和本文所提出的HC模型预测精度均较为理想,绝大多数数据点均落在5倍误差带内,大部分数据点落在3倍误差带内.这说明两种疲劳寿命预测模型能均能很好预测比例加载下材料的疲劳寿命.但是在非比例加载的情况下HC模型预测结果明显好于FS模型.HC模型预测结果绝大部分落在5倍误差带内,大部分数据点集中于2倍误差带上.而FS模型预测寿命结果较为分散,部分数据点落在5倍误差带以外.

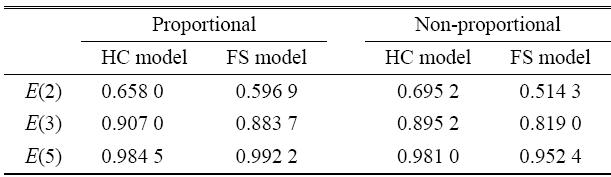

为了定量分析两种模型对材料多轴疲劳寿命的预测精度,用$E(S)$表示落在$S$倍误差带内数据点和所有数据点之间的比值[18].表2给出了两种模型在比例加载(proportional)和非比例加载(non-proportional)情况下的预测精度.可以看出HC模型和FS模型在比例加载下预测精度均十分理想,其中HC模型在$E(2)$上预测精度更高.在非比例加载情况下,HC模型预测精度比FS模型预测精度明显提高,HC模型$E(2)$和$E(3)$的预测能力为0.695 2和0.895 2,而FS模型的预测能力仅为0.5143和0.819 0.

表2 两种模型疲劳寿命预测精度比较

Table 2 Comparsion of the accuracy of different fatigue life prediction models

|

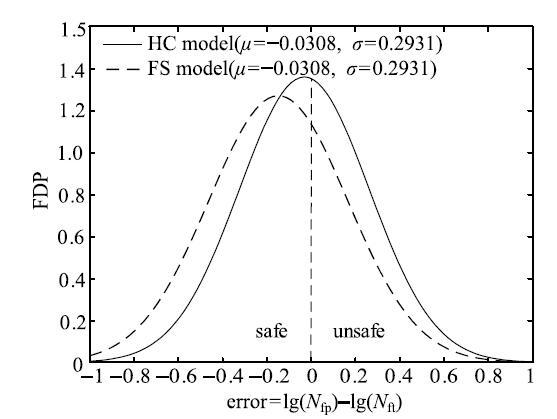

为了进一步研究本文所提出的多轴疲劳模型正确性,采用统计学方法来研究两种多轴疲劳寿命模型误差[32-33].图10给出了两种模型在多轴加载下寿命预测误差正态分布图,$N_{fp}$为预测寿命,$N_{ft}$为试验寿命,error为两者取对数后的差值,error为正数时表示预测寿命偏危险,为负数时表示预测寿命偏保守.从图中可看出两种模型的预测寿命均趋于保守一侧,HC模型的误差正态分布曲线期望均值$\mu$较FS模型误差正态分布曲线期望均值$\mu$更趋进于0,从图中还可看出HC模型均方差较FS模型均方差更小,即HC模型的数据分布更集中.以上分析说明HC模型比的预测精度更高,更可靠.

图10 两种疲劳准则预测误差的概率密度函数

Fig. 10 Probability density function of prediction errors with different fatigue criteria

5 结 论

本文在研究了材料在多轴循环载荷下疲劳寿命与加载路径间的关系,并分析了不同材料对非比例加载路径的敏感性程度的基础上,做了以下工作:

(1)考虑非比例加载过程中路径非比例度和材料非比例附加强化现象对材料疲劳寿命的影响,提出了一个新的非比例附加影响因子.该非比例附加影响因子能考虑到某些材料在没有附加强化现象时路径非比例度对材料寿命的影响,对于某些难以获得附加强化系数的材料,还可利用本文所整理得到的式(17)$\sim$式(23)对材料附加强化系数进行近似计算.

(2)基于所提出的非比例附加影响因子,结合最大剪切平面上切应变幅和最大剪切平面上正应变幅,提出一个新的多轴疲劳寿命预测模型.经8种材料的疲劳试验数据验证并与FS模型预测结果进行比较,得出两种模型预测寿命均趋向于安全一侧,且新模型预测精度更高.新模型物理意义明确,不含经验常数,方便工程实际运用,具有实际使用价值.

The authors have declared that no competing interests exist.

参考文献

| [1] |

应变局部化分析的嵌入强间断多尺度有限元法 .

固体材料的应变局部化行为是导致结构破坏失效的重要因素之一,开展相关数值模拟分析对于结构安全性评估具有重要意义.然而由于材料的非均质和多尺度特性,采用传统数值方法进行求解时通常需要从最小特征尺度离散求解的结构,这将大幅度增加计算规模和成本.针对这一问题,本文提出了一种基于嵌入强间断模型的多尺度有限元方法.该方法从粗细两个尺度离散求解模型,首先在细尺度单元上引入嵌入强间断模型来描述单元间断特性,所附加的跳跃位移自由度则通过凝聚技术进行消除,从而保持细尺度单元刚度阵维度不变.其次,提出了一种增强多节点粗单元技术,其可根据局部化带与粗单元边界相交情况自适应动态地增加粗节点,新构造的增强数值基函数可以捕捉细尺度间断特性,完成物理信息从细单元到粗单元的准确传递以及宏观响应的快速分析;再次,在细尺度解的计算中,将细尺度解分解为降尺度解与单胞局部摄动解,从而消除弹塑性分析时单胞内部的不平衡力.最后,通过两个典型算例分析,并与完全采用细单元的嵌入有限元结果进行对比,验证了所提出算法的正确性与有效性.

Embedded strong discontinuity model based multiscale finite element method for strainlocalization analysis .

固体材料的应变局部化行为是导致结构破坏失效的重要因素之一,开展相关数值模拟分析对于结构安全性评估具有重要意义.然而由于材料的非均质和多尺度特性,采用传统数值方法进行求解时通常需要从最小特征尺度离散求解的结构,这将大幅度增加计算规模和成本.针对这一问题,本文提出了一种基于嵌入强间断模型的多尺度有限元方法.该方法从粗细两个尺度离散求解模型,首先在细尺度单元上引入嵌入强间断模型来描述单元间断特性,所附加的跳跃位移自由度则通过凝聚技术进行消除,从而保持细尺度单元刚度阵维度不变.其次,提出了一种增强多节点粗单元技术,其可根据局部化带与粗单元边界相交情况自适应动态地增加粗节点,新构造的增强数值基函数可以捕捉细尺度间断特性,完成物理信息从细单元到粗单元的准确传递以及宏观响应的快速分析;再次,在细尺度解的计算中,将细尺度解分解为降尺度解与单胞局部摄动解,从而消除弹塑性分析时单胞内部的不平衡力.最后,通过两个典型算例分析,并与完全采用细单元的嵌入有限元结果进行对比,验证了所提出算法的正确性与有效性.

|

| [2] |

基于M 积分的脆性材料微缺陷等效损伤面积/体积表征 .

随着脆性材料在工程中的广泛应用,对脆性材料中微缺陷进行统一的损伤水平标定,具有重要的科学研究和工程应用价值.本研究提出一种基于M积分的材料等效损伤面积/体积标定方法,以具有相同M积分值的圆孔面积或球孔体积来标定复杂微缺陷构型的损伤水平,从而实现不同类型微缺陷真实损伤水平的统一表征.首先,基于Lagrangian能量密度函数推导了M积分定义式,并简述了M积分的物理意义,基于域积分方法实现二维/三维M积分的数值计算.随后,提出了基于M积分的材料缺陷等效损伤面积/体积标定方法,以圆孔面积/球孔体积来标定复杂微缺陷材料系统的损伤水平.最后,针对单轴拉伸载荷作用下的二维/三维脆性体含不同缺陷构型,具体计算了椭圆孔、裂纹以及双裂纹、双孔洞、裂纹和孔洞干涉等复杂缺陷构型情况下的等效损伤面积/体积,并详细分析了缺陷之间的干涉效应及影响因素.本研究旨在基于M积分等效方法量化脆性材料中各类微缺陷造成的损伤程度,实现损伤等级标定,有益于工程材料及结构的损伤容限设计及完整性评估.

The calibration of microdefects induced equivalent damage area/volume of brittle materials by usingb the M-integral .

随着脆性材料在工程中的广泛应用,对脆性材料中微缺陷进行统一的损伤水平标定,具有重要的科学研究和工程应用价值.本研究提出一种基于M积分的材料等效损伤面积/体积标定方法,以具有相同M积分值的圆孔面积或球孔体积来标定复杂微缺陷构型的损伤水平,从而实现不同类型微缺陷真实损伤水平的统一表征.首先,基于Lagrangian能量密度函数推导了M积分定义式,并简述了M积分的物理意义,基于域积分方法实现二维/三维M积分的数值计算.随后,提出了基于M积分的材料缺陷等效损伤面积/体积标定方法,以圆孔面积/球孔体积来标定复杂微缺陷材料系统的损伤水平.最后,针对单轴拉伸载荷作用下的二维/三维脆性体含不同缺陷构型,具体计算了椭圆孔、裂纹以及双裂纹、双孔洞、裂纹和孔洞干涉等复杂缺陷构型情况下的等效损伤面积/体积,并详细分析了缺陷之间的干涉效应及影响因素.本研究旨在基于M积分等效方法量化脆性材料中各类微缺陷造成的损伤程度,实现损伤等级标定,有益于工程材料及结构的损伤容限设计及完整性评估.

|

| [3] |

基于构型力断裂准则的裂纹与夹杂干涉问题 .

基于构型力概念提出一种可判断裂纹起裂以及裂纹扩展方向的新断裂准则.该准则假设当构型合力值达到一个临界值时裂纹开始扩展,而裂纹扩展的方向则为构型合力的矢量方向.基于此断裂准则,本文开发构型力的有限元计算方法,实现对裂纹扩展的数值模拟,并着重对工程中常见的含孔洞/夹杂结构的裂纹扩展问题展开研究.研究结果表明,基于构型力的裂纹扩展准则可以很好地预测裂纹与孔/夹杂的干涉作用,其数值模拟结果与实验结果相符,从而验证了该裂纹扩展模拟方法的有效性.通过对裂纹和夹杂(圆孔、软夹杂、硬夹杂)干涉问题的数值模拟表明,裂纹前端夹杂对裂纹的扩展具有重要影响.裂纹的扩展方向与裂纹和夹杂的相对位置、以及夹杂类型密切相关.软夹杂和圆孔会吸引裂纹向其扩展,而硬夹杂会排斥裂纹扩展,裂纹在扩展过程中会绕开硬夹杂.当裂纹与夹杂夹角较小时,夹杂对裂纹扩展的影响作用明显,当夹角较大时,夹杂对裂纹扩展的影响较小;特别当裂纹与夹杂夹角为45时,软夹杂和圆孔可能会抑制裂纹的扩展,使裂纹扩展发生止裂.研究结果有助于认清含孔洞/夹杂结构中的裂纹扩展或止裂问题,对于工程中的断裂问题具有重要指导意义.

Crack interacting with an individual inclusion by the fracture criterion of configurational force .

基于构型力概念提出一种可判断裂纹起裂以及裂纹扩展方向的新断裂准则.该准则假设当构型合力值达到一个临界值时裂纹开始扩展,而裂纹扩展的方向则为构型合力的矢量方向.基于此断裂准则,本文开发构型力的有限元计算方法,实现对裂纹扩展的数值模拟,并着重对工程中常见的含孔洞/夹杂结构的裂纹扩展问题展开研究.研究结果表明,基于构型力的裂纹扩展准则可以很好地预测裂纹与孔/夹杂的干涉作用,其数值模拟结果与实验结果相符,从而验证了该裂纹扩展模拟方法的有效性.通过对裂纹和夹杂(圆孔、软夹杂、硬夹杂)干涉问题的数值模拟表明,裂纹前端夹杂对裂纹的扩展具有重要影响.裂纹的扩展方向与裂纹和夹杂的相对位置、以及夹杂类型密切相关.软夹杂和圆孔会吸引裂纹向其扩展,而硬夹杂会排斥裂纹扩展,裂纹在扩展过程中会绕开硬夹杂.当裂纹与夹杂夹角较小时,夹杂对裂纹扩展的影响作用明显,当夹角较大时,夹杂对裂纹扩展的影响较小;特别当裂纹与夹杂夹角为45时,软夹杂和圆孔可能会抑制裂纹的扩展,使裂纹扩展发生止裂.研究结果有助于认清含孔洞/夹杂结构中的裂纹扩展或止裂问题,对于工程中的断裂问题具有重要指导意义.

|

| [4] |

考虑全平面损伤参量的多轴低周疲劳寿命预测方法研究 .

实际工程结构往往处于复杂的多向受力状态,在循环荷载下其薄弱点发生的疲劳断裂多属于多轴疲劳失效模式.目前疲劳寿命预测方法多集中于单轴疲劳理论,忽略了多轴疲劳问题的现实性和复杂性.首先介绍了多轴疲劳的概念和特点,回顾了多轴低周疲劳寿命预测方法,针对基于临界面准则的疲劳预测方法进行了总结归纳,对比了各模型的适用范围和优缺点.研究了多轴非比例路径下剪应变幅的变化情况,考虑了其旋转造成的全平面疲劳损伤,提出了一种新的非比例路径因子反映剪应变幅数值和方向的变化对疲劳寿命的影响,并将该系数引入FatemiSocie模型(FS模型)进行修正.通过理论值与试验值对比,发现改进后的FS模型预测精度有所提高.

Multiaxial low-cycle fatigue prediction method considering damage parameter of plane in every directionet.

实际工程结构往往处于复杂的多向受力状态,在循环荷载下其薄弱点发生的疲劳断裂多属于多轴疲劳失效模式.目前疲劳寿命预测方法多集中于单轴疲劳理论,忽略了多轴疲劳问题的现实性和复杂性.首先介绍了多轴疲劳的概念和特点,回顾了多轴低周疲劳寿命预测方法,针对基于临界面准则的疲劳预测方法进行了总结归纳,对比了各模型的适用范围和优缺点.研究了多轴非比例路径下剪应变幅的变化情况,考虑了其旋转造成的全平面疲劳损伤,提出了一种新的非比例路径因子反映剪应变幅数值和方向的变化对疲劳寿命的影响,并将该系数引入FatemiSocie模型(FS模型)进行修正.通过理论值与试验值对比,发现改进后的FS模型预测精度有所提高.

|

| [5] |

A theory for fatigue failure under multiaxial stress-strain conditions . |

| [6] |

BrownMW, Miller KJ. Biaxial low cycle fatigue fracture of 316 stainless steel at elevated temperatures . |

| [7] |

A critical plane approach to multiaxial fatigue damage including out of plane loading .

Abstract鈥 A modification to Brown and Miller's critical plane approach is proposed to predict multiaxial fatigue life under both in-phase and out-of-phase loading conditions. The components of this modified parameter consist of the maximum shear strain amplitude and the maximum normal stress on the maximum shear strain amplitude plane. Additional cyclic hardening developed during out-of-phase loading is included in the normal stress term. Also, the mathematical formulation of this new parameter is such that variable amplitude loading can be accommodated. Experimental results from tubular specimens made of 1045 HR steel under in-phase and 90掳 out-of-phase axial-torsional straining using both sinusoidal and trapezoidal wave forms were correlated within a factor of about two employing this approach. Available Inconel 718 axial-torsional data including mean strain histories were also satisfactorily correlated using the aforementioned parameter.

|

| [8] |

An energy-critical plane based fatigue damage approach for the life prediction of metal alloys .

This paper presents a new energy-critical plane based fatigue damage approach for the assessment of the fatigue life under uniaxial and multiaxial proportional and non-proportional fatigue loading. The proposed approximate method, based on Farahani's multiaxial fatigue damage model, takes into account the critical plane orientations during a loading cycle and the values of the respective damage parameters on them. The uniqueness of the proposed method lies on the fact that it considers a weighted contribution of each critical plane orientation to the material damage. The relative weighting factors depend on the declination of each critical plane with respect to the critical plane, where the damage parameters exhibit their maximum values during a fatigue loading cycle. Herein, several low, mid and high-cycle fatigue loading cases are being investigated. The induced elastic-plastic stress-strain states are approximated by means of respective finite element analyses (FEA). Several experimental fatigue data derived from uniaxial and multiaxial fatigue tests on StE460 steel alloy thin-walled hourglass-type specimens have been used to verify the model's calculation accuracy. Comparison of experimental and calculated fatigue lives confirm remarkable fatigue life calculation accuracy in all cases examined.

|

| [9] |

Multiaxial fatigue life prediction for various metallic materials based on the critical plane approach .

This paper summarizes an attempt to devise a simple method suitable for assessing fatigue lives of metallic materials subjected to both proportional and non-proportional loading conditions. This proposed approach consists of the maximum shear strain range, the normal strain range and the maximum normal stress on the maximum shear strain range plane. In order to correctly account for the presence of non-zero out-of-phase angles, the non-proportionality factor proposed by Chen et al. was introduce to evaluate the degree of multiaxiality. Besides, the accuracy of the proposed method in estimating fatigue lifetime in the presence of non-zero mean stresses was also investigated.

|

| [10] |

一种新的多轴非比例低周疲劳寿命预测临界面模型 .

<p>工程结构在服役过程中往往承受着复杂的多轴非比例循环荷载,在长期动力载荷作用下结构构件的失效主要为多轴非比例疲劳破坏. 文中基于圆管薄壁试件在拉-扭复合加载情况下的多轴疲劳试验结果,对比了广泛讨论的Kandil-Brown-Miller (KBM) 模型和Fatemi-Socie (FS) 模型对多轴非比例疲劳寿命的预测能力,分析了非比例加载条件引起多轴疲劳附加损伤的原因;针对FS 模型对不存在非比例附加强化的材料多轴疲劳寿命预测的不足,提出了一个能考虑非比例加载路径变化和材料附加强化效应双重作用的非比例影响因子,参照FS 准则提出了一种新的多轴非比例低周疲劳寿命预测临界面模型. 利用5 种材料的多轴非比例疲劳试验数据对该模型进行了试验验证,结果表明:采用文中提出的临界面模型预测的多轴非比例疲劳寿命与试验结果符合较好,预测精度优于FS 模型;同时,该模型对不存在非比例附加强化的材料的多轴疲劳寿命预测表现出更好的适用性,且能有效的提高不同类型材料的多轴非比例疲劳寿命预测精度.</p>

A new proposal for multiaxial low-cycle fatigue life prediction under non-proportional loading .

<p>工程结构在服役过程中往往承受着复杂的多轴非比例循环荷载,在长期动力载荷作用下结构构件的失效主要为多轴非比例疲劳破坏. 文中基于圆管薄壁试件在拉-扭复合加载情况下的多轴疲劳试验结果,对比了广泛讨论的Kandil-Brown-Miller (KBM) 模型和Fatemi-Socie (FS) 模型对多轴非比例疲劳寿命的预测能力,分析了非比例加载条件引起多轴疲劳附加损伤的原因;针对FS 模型对不存在非比例附加强化的材料多轴疲劳寿命预测的不足,提出了一个能考虑非比例加载路径变化和材料附加强化效应双重作用的非比例影响因子,参照FS 准则提出了一种新的多轴非比例低周疲劳寿命预测临界面模型. 利用5 种材料的多轴非比例疲劳试验数据对该模型进行了试验验证,结果表明:采用文中提出的临界面模型预测的多轴非比例疲劳寿命与试验结果符合较好,预测精度优于FS 模型;同时,该模型对不存在非比例附加强化的材料的多轴疲劳寿命预测表现出更好的适用性,且能有效的提高不同类型材料的多轴非比例疲劳寿命预测精度.</p>

|

| [11] |

考虑残余应力的焊接结构多轴疲劳准则 .

因随机波浪载荷及焊接残余应力的存在,海洋工程焊接结构的疲劳失效受多轴疲劳机理控制,然而目前的多轴疲劳准则对焊接残余应力关注较少,针对上述问题文中通过将不包含焊接残余应力的有限元计算应力场与焊接残余应力场线性叠加作为多轴疲劳寿命计算应力场,提出了一种基于临界面法的多轴疲劳寿命预测准则,通过对国际上已公开发表的疲劳试验数据进行有限元分析并与多轴疲劳准则MWCM对比,证明文中方法比MWCM具有更高的准确性,对于非比例载荷作用下的疲劳寿命预测效果尤为显著,同时证明了文中方法可以有效考虑焊接残余应力的影响.

Multiaxial fatigue criteria of welded structures considering the residual stress .

因随机波浪载荷及焊接残余应力的存在,海洋工程焊接结构的疲劳失效受多轴疲劳机理控制,然而目前的多轴疲劳准则对焊接残余应力关注较少,针对上述问题文中通过将不包含焊接残余应力的有限元计算应力场与焊接残余应力场线性叠加作为多轴疲劳寿命计算应力场,提出了一种基于临界面法的多轴疲劳寿命预测准则,通过对国际上已公开发表的疲劳试验数据进行有限元分析并与多轴疲劳准则MWCM对比,证明文中方法比MWCM具有更高的准确性,对于非比例载荷作用下的疲劳寿命预测效果尤为显著,同时证明了文中方法可以有效考虑焊接残余应力的影响.

|

| [12] |

多轴疲劳寿命预测方法 .

在工程实际中,大多数工程结构和机械零件都承受着各种形式的循环载荷,载荷分布大多呈现多轴应力状态。在循环荷载作用下,对多轴疲劳寿命的研究比单轴的更加接近工程实际,有更广泛的应用背景。针对这一现状,本文详述了近年来国内外关于多轴疲劳寿命预测方法的研究现状,分别介绍了等效应变法、能量法、临界面法三种主流方法的基本原理及优缺点,并将这三种方法做了简单对比。另外,针对现阶段各类多轴疲劳寿命预测方法的不足,提出了今后在多轴疲劳领域研究工作的设想。

Summarization of multi-axial fatigue life prediction methods .

在工程实际中,大多数工程结构和机械零件都承受着各种形式的循环载荷,载荷分布大多呈现多轴应力状态。在循环荷载作用下,对多轴疲劳寿命的研究比单轴的更加接近工程实际,有更广泛的应用背景。针对这一现状,本文详述了近年来国内外关于多轴疲劳寿命预测方法的研究现状,分别介绍了等效应变法、能量法、临界面法三种主流方法的基本原理及优缺点,并将这三种方法做了简单对比。另外,针对现阶段各类多轴疲劳寿命预测方法的不足,提出了今后在多轴疲劳领域研究工作的设想。

|

| [13] |

A review of multiaxial fatigue criteria for random variable amplitude loads .

Nowadays, the estimation of fatigue life under multiaxial random loading is still an extremely complex task. In this paper, a comprehensive review of the multiaxial random fatigue criteria available in the literature is presented. Such a review is mainly devoted to stress‐based criteria for the evaluation of fatigue life in high‐cycle regime. Time and frequency domain approaches are examined. The focus of this paper is related to uniform stress/strain distribution, but also the effect of stress/strain gradient is tangentially addressed. More than 200 references are cited.

|

| [14] |

Low-cycle fatigue under non-proportional loading . |

| [15] |

Nonproportional Low cycle fatigue of 6061 aluminum alloy under 14 strain paths . |

| [16] |

A survey on multiaxial fatigue damage parameters under non-proportional loadings .

In this paper, several multiaxial fatigue damage parameters taking into account non-proportional additional hardening are reviewed. According to the way non-proportional additional hardening is considered in the model, the damage parameters are classified into two categories: (i) equivalent damage parameters and (ii) direct damage parameters. The equivalent damage parameters usually define a non-proportional coefficient to consider non-proportional additional cyclic hardening, and make a combination of this non-proportional coefficient with stress and/or strain quantities to calculate the equivalent damage parameters. In contrast, the direct damage parameters are directly estimated from the stress and strain quantities of interest. The accuracy of four multiaxial fatigue damage parameters in predicting fatigue lifetime is checked against about 150 groups of experimental data for 10 different metallic materials under multiaxial fatigue loading. The results revealed that both Itoh鈥檚 model, one of equivalent damage parameters, and Suemel鈥檚 model, which belong to direct damage parameters, could provide a better correlation with the experimental results than others assessed in this paper. So, direct damage parameters are not better than the equivalent damage parameters in predicting fatigue lifetime.

|

| [17] |

Additional cyclic strain hardening and its relation to material structure, mechanical characteristics, and lifetime .

The authors have analyzed the susceptibility of metallic materials to cyclic strain hardening depending on both their microphysical characteristics and macrophysical parameters represented by standard mechanical characteristics. At the microlevel, the degree of additional hardening is related to the material stacking fault energy. The materials with a high level of the stacking fault energy do not exhibit additional cyclic hardening under non-proportional loading, while those with a low energy are susceptible to a considerable strain hardening. For the macrolevel, on the basis of analysis of the mechanical properties of metallic materials, the authors have derived a correlation dependence between the hardening levels under static and cyclic loading. An approximate quantitative method to determine maximum strain hardening levels under non-proportional low-cycle strain-controlled loading is proposed. The lifetime under non-proportional loading has been shown to correlate well with the level of additional hardening.

|

| [18] |

考虑非比例附加损伤的多轴低周疲劳寿命模型 .

<p>基于临界面法, 提出了一种能够反映非比例疲劳寿命锐减现象的多轴低周疲劳寿命模型. 与传统临界面模型只考虑附加强化效果不同, 新的模型在疲劳损伤参量中引入新定义的非比例附加损伤系数, 能综合考虑非比例加载条件下附加强化和载荷路径两种因素对疲劳寿命减少的影响, 并且分别以最大切应变和最大损伤平面作为临界面来构建疲劳损伤参量, 反映了临界面的选取对模型预测结果的重要影响. 从已发表文献中选用8 种材料的多轴疲劳试验结果进行验证, 新模型能同时适用于比例和非比例加载, 并且具有很好的寿命预测精度和材料适用性.</p>

A new multiaxial fatigue life prediction model based on the nonproportional additional damage .

<p>基于临界面法, 提出了一种能够反映非比例疲劳寿命锐减现象的多轴低周疲劳寿命模型. 与传统临界面模型只考虑附加强化效果不同, 新的模型在疲劳损伤参量中引入新定义的非比例附加损伤系数, 能综合考虑非比例加载条件下附加强化和载荷路径两种因素对疲劳寿命减少的影响, 并且分别以最大切应变和最大损伤平面作为临界面来构建疲劳损伤参量, 反映了临界面的选取对模型预测结果的重要影响. 从已发表文献中选用8 种材料的多轴疲劳试验结果进行验证, 新模型能同时适用于比例和非比例加载, 并且具有很好的寿命预测精度和材料适用性.</p>

|

| [19] |

多轴非比例载荷下金属材料的疲劳寿命预测. [硕士论文] .Fatigue life prediction of metal under multiaxial nonproportional loading. [Master Thesis] . |

| [20] |

Effect of microstructure and hardness on non-proportional cyclic hardening coefficient and predictions .

This paper investigates the effects of microstructure and hardness on non-proportional cyclic hardening of metallic materials. Constant amplitude in-phase and 90掳 out-of-phase strain-controlled axial-torsion cyclic tests were conducted to evaluate the hardening. Tubular specimens made from 1050 steel in normalized, quenched and tempered, and induction hardened conditions as well as 304L stainless steel were used to study the effect of microstructure on multiaxial cyclic deformation. Reductions in the non-proportional cyclic hardening were observed as the microstructure of 1050 steel changed form pearlitic鈥揻erritic with lower hardness to tempered martensite with higher hardness. Significant non-proportional cyclic hardening was also observed for 304L stainless steel with austenitic microstructure. Multiaxial data generated in this study as well as multiaxial deformation data of several materials from literature suggest non-proportional cyclic hardening can be related to uniaxial cyclic hardening. Non-proportional hardening coefficients predicted from a proposed equation based on this observation were found to be in very good agreement with the experimental values in this study and from the literature.

|

| [21] |

形变硬化指数与强度的关系 .

从硬化指数的定义出发导出了形变硬化指数n与强度参量之间的关系为n=A(1-σⅠ-/σⅡ)+B,σⅠ和σⅡ为真应力应变曲线上一直线段两端点的应用力,A和B为常数,它适用于单一n值情况,双n特性,单调加载和循环应力应弯曲线,对均匀变形阶段,又导出了n和屈强比的关系,即n=1-√σs/σb,该式没有任何特定常数和经验常数,和测量值相比90%以上的数据的绝对误差在±0.03以内,它表示了材料的均匀变形能力

Relation between strain-hardening exponent and strength .

从硬化指数的定义出发导出了形变硬化指数n与强度参量之间的关系为n=A(1-σⅠ-/σⅡ)+B,σⅠ和σⅡ为真应力应变曲线上一直线段两端点的应用力,A和B为常数,它适用于单一n值情况,双n特性,单调加载和循环应力应弯曲线,对均匀变形阶段,又导出了n和屈强比的关系,即n=1-√σs/σb,该式没有任何特定常数和经验常数,和测量值相比90%以上的数据的绝对误差在±0.03以内,它表示了材料的均匀变形能力

|

| [22] |

金属板料幂指型硬化模型应变强化系数K值研究 .

应变强化指数n值因同时体现金属板料胀形、压延等成形性能优劣, 甚至与材料的宏观断裂和疲劳特性也存在一定关系,故已成为评价其冲压成形性能的主要材料参数而获得广泛关注.而幂指型硬化模型的另一重要参数--强化系数 K值,前期研究虽表明其对板料的冲压成形性能也有重要影响,但目前对其在冲压成形性方面的研究甚少.文章以金属板料单向拉伸塑性失稳点特性为基础,结合硬 化模型在该点附近较好地与板料真实应力-应变曲线相符合的基本假设,详细推导了K值与抗拉强度σb和n值之间解析关系,并基于该解析关系讨论了K值与n值 在评价板料成形性能方面的一致性.结果表明,K值可作为衡量板料成形性能的综合指标,为研究金属板料成形能力评价方法打开了新的思路.通过实验证明了该解 析结果的正确性及其工程适用性.

Research on strength coefficient in power hardening model of sheet metal .

应变强化指数n值因同时体现金属板料胀形、压延等成形性能优劣, 甚至与材料的宏观断裂和疲劳特性也存在一定关系,故已成为评价其冲压成形性能的主要材料参数而获得广泛关注.而幂指型硬化模型的另一重要参数--强化系数 K值,前期研究虽表明其对板料的冲压成形性能也有重要影响,但目前对其在冲压成形性方面的研究甚少.文章以金属板料单向拉伸塑性失稳点特性为基础,结合硬 化模型在该点附近较好地与板料真实应力-应变曲线相符合的基本假设,详细推导了K值与抗拉强度σb和n值之间解析关系,并基于该解析关系讨论了K值与n值 在评价板料成形性能方面的一致性.结果表明,K值可作为衡量板料成形性能的综合指标,为研究金属板料成形能力评价方法打开了新的思路.通过实验证明了该解 析结果的正确性及其工程适用性.

|

| [23] |

A method of predicting cyclic stress--strain curve from tensile properties for steels .

Cyclic loading can significantly alter the monotonic deformation resistance of a material. Knowledge of the cyclic deformation behavior of a material is essential for reliable life calculations of cyclically loaded structures. As monotonic tensile properties are commonly available or easily obtainable from a simple tension test, the objective of this study was to derive a method for estimating the cyclic deformation properties of steels from common tensile properties and hardness. A variety of correlations and relationships among hardness, tensile properties, and cyclic deformation properties were developed for fifty-seven steels included in this study. Several correlations and relations from the literature among the aforementioned properties were also examined and compared to the correlations and relationships proposed in this study using a different set of data from sixty-six steels. Implications of the proposed cyclic deformation behavior estimation method on fatigue life predictions are also discussed.

|

| [24] |

Fracture mechanisms and life assessment under high-strain biaxial cyclic loading of type 304 stainless steel .

Abstract— In order to investigate the elevated-temperature low-cycle fatigue characteristics of Type 304 stainless steel under biaxial loading, strain-controlled push-pull and torsional fatigue tests were conducted at 550°C under proportional and nonproportional loading conditions with phase differences of 0, α/6, α/4, α/3 and α/2 between the applied sinusoidal axial and torsional strains. Based on the experimental results, this study presents a discussion on fracture mechanisms and failure criteria. In the case of proportional loading, the fracture mode was found, from fractographic observations, to be classified into either Mode I or Mode II, while the fractures were of mixed mode under nonproportional loading. However, failure lives under both the loading conditions could be correlated well in this study with the equivalent shear strain range, Δy, defined by extending the β -plane theory of Brown and Miller. The failure life under nonproportional loading could also be predicted by applying a strain-energy-based approach.

|

| [25] |

Multiaxial fatigue damage models . |

| [26] |

In-phase and out-of-phase axial-torsional fatigue behavior of Haynes 188 at 760C.

Isothermal, in-phase and out-of-phase axial-torsional fatigue experiments have been conducted at 760 C on uniform gage section, thin-walled tubular specimens of a wrought cobalt-base superalloy, Haynes 188. Test-control and data acquisition were accomplished with a minicomputer. Fatigue lives of the in- and out-of-phase axial-torsional fatigue tests have been estimated with four different multiaxial fatigue life prediction models that were developed primarly for predicting axial-torsional fatigue lives at room temperature. The models investigated were: (1) the von Mises equivalent strain range; (2) the Modified Multiaxiality Factor Approach; (3) the Modified Smith-Watson-Topper Parameter; and (4) the critical shear plane method of Fatemi, Socie, and Kurath. In general, life predictions by the von Mises equivalent strain range model were within a factor of 2 for a majority of the tests and the predictions by the Modified Multiaxiality Factor Approach were within a factor of 2, while predictions of the Modified Smith-Watson-Topper Parameter and of the critical shear plane method of Fatemi, Socie, and Kurath were unconservative and conservative, respectively, by up to factors of 4. In some of the specimens tested under combined axial-torsional loading conditions, fatigue cracks initiated near extensometer indentations. Two design modifications have been proposed to the thin-walled tubular specimen to overcome this problem.

|

| [27] |

Multiaxial fatigue of 16MnR steel . |

| [28] |

Multiaxial fatigue of titanium including step loading and load path alteration and sequence effects .

Load sequence effects on low cycle multiaxial fatigue behavior of titanium are investigated in this study. Constant and variable amplitude axial, torsion, as well as in-phase and out-of-phase axial–torsion strain-controlled tests were conducted on tubular specimens made from pure titanium and titanium alloy BT9. Load non-proportionality had no effect on deformation behavior and cyclic stress–strain data were correlated by von Mises equivalent criterion. However, non-proportional loading resulted in significantly shorter lives and fatigue data could not be correlated by the von Mises criterion. The Fatemi–Socie (FS) critical plane parameter was found to correlate constant amplitude data of both titanium grades very well. von Mises criterion and the critical plane parameter in combination with the linear cumulative damage rule were also employed for fatigue life prediction of both materials under various block loadings with different combinations of axial, torsion, and 90° out-of-phase strain paths. Predicted low cycle fatigue lives based on linear damage rule and the FS critical plane approach were in good agreements with the experimental observations. Predicted failure planes by the critical plane parameter were also found to be consistent with experimentally observed failure planes for all the loading blocks used in the experimental study.

|

| [29] |

Prediction of fatigue lifetime under multiaxial cyclic loading using finite element analysis .

Life prediction for GH4169 superalloy thin tubular and notched specimens were investigated under proportional and nonproportional loading with elastic–plastic finite element analysis (FEA). A strain-controlled tension–torsion loading was carried out by applying the axial and circular displacements on one end of the specimen in the cylindrical coordinate system. Uniaxial cyclic stress–strain data at high temperature were used to describe the multi-linear kinematic hardening of the material. The comparison between FEA and experimental results for thin tubular specimen showed that the built model of FE is reliable. A fatigue damage parameter was proposed to predict the fatigue crack initiation life for notched specimen. The results showed that a good agreement was achieved with experimental data.

|

| [30] |

Effect of hardness on multiaxial fatigue behaviour and some simple approximations for steels .

Constant-amplitude in-phase and 90° out-of-phase axial-torsional fatigue tests were conducted on tubular specimens made from a medium-carbon steel with three hardness levels obtained from normalizing, quenching and tempering and induction hardening to find the effect of hardness on multiaxial fatigue behaviour. In addition, the same loadings were applied on the normalized solid specimens to investigate the effect of specimen geometry on multiaxial fatigue life. Similar fatigue life variation as a function of hardness was found for in-phase and out-of-phase loadings, with higher ductility beneficial in low-cycle fatigue (LCF) and higher strength beneficial in high-cycle fatigue (HCF). Multiaxial fatigue data were satisfactorily correlated for all hardness levels with the Fatemi–Socie parameter. Furthermore, in order to predict multiaxial fatigue life of steels in the absence of any fatigue data, the Roessle–Fatemi hardness method was used. Multiaxial fatigue lives were predicted fairly accurately using the Fatemi–Socie multiaxial model based on only the hardness level of the material. The applicability of the prediction method based on hardness was also examined for Inconel 718 and a stainless steel under a wide range of loading conditions. The great majority of the observed fatigue lives were found to be in good agreement with predicted lives.

|

| [31] |

Fatigue of 7075-T651 aluminum alloy .

Extensive fatigue experiments were conducted using 7075-T651 aluminum alloy under uniaxial, torsion, and axial-torsion loading. Detailed fatigue results were reported. Different mean stresses were applied in the experiments and the mean stress was found to have a significant influence on the fatigue strength of the material. A tensile mean stress decreased the fatigue strength dramatically. Fatigue damage was found to occur under compression鈥揷ompression loading. In addition, axial-torsion experiments using tubular specimens were conducted under different loading paths to study the multiaxial fatigue behavior. Fatigue cracking behavior was found to be dependent on the loading path as well as the loading magnitude. When the loading magnitude was high, the material displayed shear cracking. When the loading stress was below a certain level, the material exhibited tensile cracking. For most loading cases under investigation, the material displayed a mixed cracking behavior. A kink was found in the shear strain versus fatigue life curve from the pure torsion experiments, and it was associated with a distinctive transition of cracking behavior. The Smith鈥揥atson鈥揟opper (SWT) parameter with a critical plane interpretation was found to correlate well with most of the experiments conducted in terms of fatigue lives. However, the SWT parameter cannot deal with the uniaxial fatigue conditions where the maximum stress is low or negative. More importantly, the model fails to correctly predict the cracking behavior observed experimentally on the material. A critical plane criterion based on a combination of the normal and shear components of the stresses and strains on material planes was found to better correlate the fatigue experiments in terms of both fatigue life and cracking behavior. The characteristics of the multiaxial fatigue criterion were discussed based on the experimental observations on 7075-T651 aluminum alloy.

|

| [32] |

Multiaxial fatigue life assessment of sintered porous iron under proportional and non-proportional loadings .

Sintered metals are increasingly applied to high performance mechanical parts with limited fatigue life in the automobile industry. The present work focus on quantifying the multiaxial cyclic deformation and fatigue behavior of sintered metals under multiaxial loading conditions. The fatigue experiment includes 40 specimens under 7 strain-controlled proportional and non-proportional loadings. The cyclic deformation behavior under various loading conditions are investigated for sintered iron with density 7.2 g/cm 3 . The multiaxial fatigue life of the sintered metals is evaluated based on three multiaxial fatigue criteria, Smith-Watson-Tropper (SWT) criterion, the virtual strain energy criterion and the modified SWT criterion. Based on the statistic analysis of the prediction error, it is shown that the modified SWT model provides satisfactory fatigue life predictions under proportional and non-proportional loading paths. Furthermore, the cracking behavior of sintered metal is assessed with the critical plane models and discussed.

|

| [33] |

基于临界面--损伤参量法的涡轮盘多轴疲劳寿命预测.

基于临界面法对某高压涡轮(HPT)盘及GH4169合金试样进行多轴疲劳寿命预测,得出SWT(Smith-WatsonTopper)模型对单轴疲劳具有较好的预测效果而对多轴疲劳的预测效果较差,Fatemi-Socie(FS)模型也能较好地预测单轴加载下的疲劳寿命,但FS模型仅考虑最大剪应变幅平面上的正应力对疲劳损伤的影响,导致其多轴疲劳寿命预测偏保守。基于此,本文以最大剪应变幅为主要损伤控制参数,同时以最大剪应变幅平面上的正应力和正应变组成的修正参数作为多轴疲劳损伤的第二控制参数,提出了一个新的多轴疲劳临界面-损伤参量模型。结合GH4169合金及某高压涡轮盘试验验证。结果表明,对比SWT、FS和Wang-Brown(WB)模型,新模型的多轴疲劳寿命预测精度更高。

Multiaxial fatigue life prediction of an HPT disc based on critical plane-damage parameter .

基于临界面法对某高压涡轮(HPT)盘及GH4169合金试样进行多轴疲劳寿命预测,得出SWT(Smith-WatsonTopper)模型对单轴疲劳具有较好的预测效果而对多轴疲劳的预测效果较差,Fatemi-Socie(FS)模型也能较好地预测单轴加载下的疲劳寿命,但FS模型仅考虑最大剪应变幅平面上的正应力对疲劳损伤的影响,导致其多轴疲劳寿命预测偏保守。基于此,本文以最大剪应变幅为主要损伤控制参数,同时以最大剪应变幅平面上的正应力和正应变组成的修正参数作为多轴疲劳损伤的第二控制参数,提出了一个新的多轴疲劳临界面-损伤参量模型。结合GH4169合金及某高压涡轮盘试验验证。结果表明,对比SWT、FS和Wang-Brown(WB)模型,新模型的多轴疲劳寿命预测精度更高。

|

/

| 〈 |

|

〉 |