引 言

颗粒物质是指粒径大于1μm的大量离散固体颗粒组成的宏观复杂体系. 在受到周期性竖直振动激励时,颗粒物质呈现出复杂而奇特的行为,例如:当竖直振动装有颗粒的容器时,颗粒会出现隆起、对流和分离[1-3];当竖直振动填充有颗粒的U形管(容器)时,颗粒将由U形管(容器)的一个分支向另一个分支迁移[4-6]. 最近的实验发现,将一根细管竖直插入填充有颗粒的容器中,并对管施加竖直振动,颗粒将沿管发生上升运动,并最终在管内形成一个稳定的颗粒柱高度[7-9]. 这种现象与液体在浸没于液池中的细管内发生毛细效应的现象类似,因此被称为颗粒毛细效应[10-11]. 颗粒毛细效应为颗粒物料的逆重力输送提供了一种全新的途径,其具有结构简单、操作方便、不易堵塞的特点,且能够在真空条件下进行,因而富有实际应用潜力.

竖直振动下颗粒物质动力学是颗粒物质研究领域的一个重要分支,然而已有相关研究主要集中在竖直振动颗粒床内颗粒行为模式方面[12-15]. 在颗粒毛细效应发生的系统中,颗粒床不发生振动,而插入其中的管发生振动,振动系统的差异导致颗粒的动力学行为明显不同. 2013年,Liu等[7]率先针对插入颗粒床的直管发生竖直振动时颗粒的行为模式进行实验研究,发现在一定的振动强度下,颗粒能够沿管迅速上升,并最终稳定在一定的高度. 2014年,Liu等[8]对振动管管口进行改进,实验研究了颗粒在竖直振动的锥形口管的上升现象,发现与采用直管相比,颗粒能够在更低的振动强度下发生上升;张富翁等[9]将颗粒床的竖直壁面视为周期性边界,基于离散元方法模拟了第一个振动周期内颗粒的受力状况,但未能给出颗粒上升直至稳定的过程. 2015年,Liu与Zhao[16]基于实验报道的颗粒上升特性,建立了颗粒上升高度随时间变化的半经验关系式,并根据能量平衡关系推导出最终上升高度的表达式. 2016年,刘举等[12]对竖直振动下颗粒物质行为模式研究进展进行总结和评述,提出了采用离散元方法,并将颗粒床的壁面视为有摩擦的固体壁面边界条件,对颗粒在竖直振动管中上升的动力学行为和机理开展研究的新思路. 2017年,Fan等[10-11]基于竖直振动管中颗粒上升与液体毛细效应在现象上的相似性,称之为颗粒毛细效应,并利用离散元模拟针对其物理机制开展研究,发现了颗粒毛细效应的对流机制,揭示了颗粒最终毛细上升高度随管径的变化规律. 2017年,Xu等[17]同样采用离散元模拟方法,分析了管内颗粒时均填充率沿管轴线的分布情况,考察了振动条件、恢复系数对颗粒上升高度演变过程的影响. 2018年,Zhang等[18]实验研究了振动条件和管插入深度对颗粒上升的影响.

尽管上述实验研究和离散元模拟在颗粒毛细效应的宏观行为和内在机理上取得了重要进展,然而由于所研究颗粒体系的复杂性和控制参数的多样性,目前对颗粒毛细效应动力学行为的认识仍不够,并且受实验手段和测量仪器的限制,颗粒动力学行为的问题也难以通过实验得到完全解决. 基于颗粒的离散元方法能够跟踪到每一个颗粒的运动轨迹,从而可以直接获得颗粒物质复杂行为的细节信息以及不易测量的颗粒尺度行为规律,是研究颗粒体系动力学行为的行之有效的方法,是对实验研究的有力补充[19-21]. 因此,本文利用离散元方法针对颗粒毛细效应过程开展数值模拟研究,以获取颗粒毛细效应的动力学行为规律及其机理,从而为认识和理解复杂颗粒系统动力学行为提供基础.

1 颗粒毛细效应的离散元模拟方法

1.1 基于离散元方法的颗粒运动模型

离散元方法的基本思想是将颗粒材料视为离散颗粒的集合,各离散颗粒满足牛顿第二定律决定的运动方程,用时步迭代方法求解各离散颗粒的运动方程,从而获得颗粒体系的行为规律.

根据牛顿第二定律,颗粒体系中任意颗粒i的运动方程可写为

式中,$m_{i}$和$I_{i}$分别为颗粒i的质量和转动惯量,${\pmb v}_{i}$和${\pmb\omega }_{i}$分别为颗粒i的速度和角速度,$t$为时间,${\pmb g}$为重力加速度,$N$为与颗粒i相接触的颗粒的个数,${\pmb F}_{{\rm n},ij}$和${\pmb F}_{{\rm t},ij}$分别为与颗粒i相接触的颗粒j对颗粒i的法向和切向作用力,${\pmb M}_{{\rm t},ij}$为颗粒j对颗粒i的切向作用力产生的力矩,${\pmb M}_{{\rm r},ij}$为颗粒j对颗粒i的滚动摩擦力产生的力矩.

取决于颗粒形状和物性,描述颗粒间接触力的模型有多种. 本文利用黏弹性接触模型[22]计算法向作用力,即

式中,$\rho$为弹性参数,其是杨氏模量$Y$、泊松比$\upsilon$和有效半径$R_{\rm eff}$的函数;$\delta_{{\rm n},ij} = R_{i}+R_{j}-\vert {\pmb r}_{i}-{\pmb r}_{j}\vert$为颗粒i与颗粒j的法向重叠量,$R_{i}$和$R_{j}$分别为颗粒i和j的半径,${\pmb r}_{i}$和${\pmb r}_{j}$分别为颗粒i和j的位置矢量,$A_{\rm n}$为法向耗散参数,其由颗粒材料黏度决定, 由于$A_{\rm n}$往往是未知量,本文根据基于Padé近似的$A_{\rm n}$与恢复系数$\varepsilon$ 的关系式[23]对$A_{n}$进行计算;${\pmb e}_{\rm n} = ( {\pmb r}_{j}-{\pmb r}_{i})/ | {\pmb r}_{j}-{\pmb r}_{i}|$为法向单位矢量.

弹性参数$\rho$ 的表达式为

其中,$R_{\rm eff}=R_{i}R_{j}/(R_{i}+R_{j})$.

采用修正的Cundall-Strack模型[24]计算切向作用力,即

根据定向恒转矩模型[27],${\pmb M}_{{\rm r},ij}$可写为

式中,$\mu_{\rm r}$为滚动摩擦系数,${\pmb \omega}_{ij }= {\pmb \omega}_{i}-{\pmb \omega}_{j}$为颗粒i与j的相对角速度.

对于颗粒与壁面的相互作用,将壁面按粒径为无限大的颗粒处理.

1.2 模拟参数和实施方案

2013年,Liu等[7]实验观测到颗粒毛细效应时采用的实验系统如图1所示,直径为140 mm的圆柱形容器内填充有平均粒径为0.3 mm、密度为2556 kg/m$^{3}$的玻璃珠颗粒,颗粒堆积密度为1542 kg/m$^{3}$、填充高度为110 mm;将内径为8 mm、壁厚为1 mm、长度为400 mm的透明有机玻璃管竖直插入颗粒层中,插入深度为30 mm;管通过夹具固定在电磁振动台上,通过电磁振动台对管施加竖直方向正弦振动,振动频率$f = 12$ Hz、无量纲振动强度$\varGamma = 5$. 图1同时给出了Liu等[7]实验观测到的颗粒毛细上升过程,图1(a)~图1(c)分别为振动开始时刻、振动开始后$60 T$和$204 T$时刻,其中$T = 1/ f$为振动周期.

图1

4mm 由于实验系统中颗粒数目庞大(约7.2×10$^{7}$个),数值模拟时若采用和实验完全一致的颗粒系统,计算量将是非常惊人的.为减小计算体系中的颗粒量,以降低计算代价,本文所研究的颗粒系统初始状态如图2所示,盛装颗粒的容器为圆柱形,底面直径$D = 28.2$ mm,底面位于$z =-30$ mm处;管竖直插入容器中心,底面中心位于坐标原点,管内径$d = 8$ mm,管壁厚为0.6 mm;颗粒直径$d_{\rm p} = 0.6$ mm,颗粒数目为2.0×10$^{5}$个,管内、外颗粒表面高度基本相同,颗粒处于静止状态;容器高度和管的长度足够大,以保证计算过程中颗粒始终在容器与管的内部.

图2

图2

模拟采用的颗粒系统初始状态示意图

Fig.2

Schematic of initial state of the granular system used in simulation

对管施加竖直振动时,管底面所处高度$z_{\rm b}$的变化规律为

式中,A为振幅,振动起始时刻$t = 0$. 数值模拟时,采用$A = 12.42$ mm,$f = 10$ Hz,对应于无量纲振动强度$\varGamma = A (2 π f ) ^{2}/g \approx 5$.

容器和管的壁面均采用有摩擦的固体壁面边界条件进行处理,模拟采用的颗粒物性参数见表1.

表1 模拟采用的颗粒物性参数

Table 1

| Parameter | Symbol | Value |

|---|---|---|

| particle density / (kg*m-3) | pp | 2500 |

| Young’s modulus / MPa | Y | 10 |

| Poisson’s ratio | V | 0.25 |

| coefficient of restitution | e | 0.5 |

| particle-particle sliding friction coefficient | 0.8 | |

| particle-wall sliding friction coefficient | WW | 0.58 |

| particle-particle rolling friction coefficient | 0.1 | |

| particle-wall rolling friction coefficient | 0.05 |

在选择时间步长时,需要兼顾数值计算的精确性和时间成本. 为此,利用无阻尼、无黏性碰撞时间表达式估算颗粒碰 撞时间[28]

式中,$M_{\rm eff} = M_{i}M_{j} /( M_{i}+M_{j})$为有效质量;$v_{\rm imp}$为碰撞速度. 选择系统中颗粒碰撞速度的上限作为碰撞速度, 则有$v_{\rm imp } \approx 1$ m/s,代入式(8),得到碰撞时间$T_{\rm col} \approx 6.0 \times 10^{-5 }$ s.

在上述模型和计算条件的基础上,借助开源颗粒系统离散元模拟软件LIGGGHTS[31]针对颗粒毛细效应动力学行为进行模拟计算. 计算平台为配备有 Intel Core i7-4790 CPU的工作站,采用4个处理器并行计算,完成振动开始后100$T$的计算耗时约为45 h.

2 结果与讨论

2.1 颗粒毛细效应过程

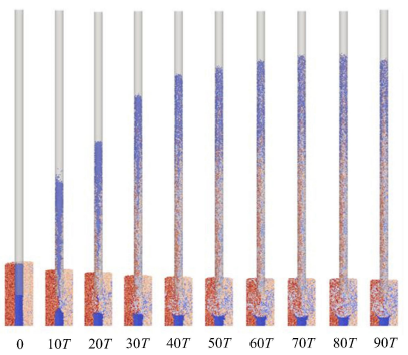

图3给出了数值模拟得到的颗粒毛细效应过程. 为了直观展示颗粒由容器内向管内的传输特性,图3给出的是将计算空间沿$y = 0$截面剖开,保留$y \leqslant 0$部分的y向视图. 图中颗粒颜色表征颗粒初始位置,$t = 0$时刻位于与管同轴且直径与管内径d相同的圆柱形区域的颗粒为蓝色.由图3可见,对管施加竖直振动后,颗粒沿管上升,并最终在管内形成一个稳定的颗粒柱高度,这与图1中Liu等[7]报道的实验现象取得定性一致.由图还可以看出,容器内出现中心区域颗粒下降、器壁附近颗粒上升的颗粒对流现象.虽然本文数值模拟采用的容器形状、尺寸、颗粒数目、振动条件与文献[10]不同,但是对流现象和文献[10]中报道的一致.颗粒毛细效应的机理可通过容器内颗粒的对流进行解释,即竖直振动下,管外壁与邻近颗粒由于摩擦引起的剪切力作用促使容器内颗粒出现对流运动,从而在容器中部形成将容器内颗粒输送到管底部的横向颗粒质量通量,使容器内颗粒填充到管向上运动时留下的空穴内,迫使管内颗粒量增加,颗粒柱高度上升;随着振动的进行,管内颗粒速度不断演变,最终管内出现颗粒对流现象,当管内颗粒柱在管下端产生的压力与管外颗粒在同一位置产生的压力相平衡时,颗粒系统达到最终的稳定状态,管内颗粒柱高度达到稳定值[10-11].此外,保持容器和管的初始位置以及计算颗粒量不变,而改变初始时刻管内颗粒柱高度,数值模拟结果显示,对管施加同样的竖直振动后,最终管内形成相同的稳定颗粒柱高度,这与文献[9]报道的实验现象一致.作为示例,图4给出了数值模拟得到的管内初始颗粒柱高度高于图3中颗粒毛细上升最终稳定颗粒柱高度的条件下颗粒毛细效应过程.由图4可见,振动开始后(0~10$T$)管内颗粒发生膨胀,颗粒柱高度有所上升,之后颗粒柱高度下降并最终达到与图3相同的稳定值.

图3

图3

数值模拟得到的颗粒毛细上升过程

Fig.3

Process of capillary rise of particles obtained by numerical simulation

图4

图4

初始颗粒柱高度高于最终稳定颗粒柱高度时颗粒毛细效应过程

Fig.4

Process of granular capillarity at the initial granular column height greater than the final steady-state granular column height

鉴于颗粒毛细上升过程在颗粒输运和提升方面具有应用潜力,以下各节仅针对图3的颗粒毛细上升现象中的行为和特性进行分析.

2.2 管内颗粒柱高度随时间的演变

为了定量分析管内颗粒柱高度,即管内颗粒表面高度$z_{\rm in}$和管外容器内颗粒表面高度$z_{\rm out}$之差随时间的演变情况,将管内区域沿z轴划分为高度$\Delta z = 5 d_{\rm p}$的等体积单元,并计算各单元内颗粒填充率

式中,$N_{\rm c}$为计算单元内颗粒数目.

选择填充率阈值$\phi_{\rm cr }= 0.1$,并定义满足填充率$\phi > \phi _{\rm cr}$的单元的最大高度z为管内颗粒表面高度$z_{\rm in}$. 类似地,将容器内$r > R_{\rm tube}$区域沿z轴划分为高度$\Delta z = d_{\rm p}$的等体积单元,计算各单元内颗粒填充率,采用相同的方法确定管外容器内颗粒表面高度$z_{\rm out}$.

图5给出了管内颗粒柱高度($z_{\rm in}-z_{\rm out})$随时间的演变,$z_{\rm in}$和$z_{\rm out}$的演变也同时给出.由图可知,在前两个振动周期$(2 T)$内,管内颗粒柱高度迅速增大并达到一个峰值后下降到初始高度,这是由于初始效应引起的.忽略初始效应,颗粒毛细效应过程可分为单周期上升$(2T < t \leqslant 9T)$、倍周期上升$(9T < t \leqslant 70T)$和倍周期稳定$(t > 70T)$三个阶段,图中分别用I、II、III标示.在单周期上升阶段,管内颗粒柱高度以约为10 mm(略小于A)的振幅发生周期性波动,波动周期和管的振动周期一致;同时,每经历一个波动周期,颗粒柱高度有明显上升,上升速度为常数,约为71.3 mm/s.在倍周期上升阶段,管内颗粒柱高度以约为25 mm ($ \approx 2A$)的振幅波动,波动周期为2$T$,每个波动周期颗粒柱上升速度逐渐减小直至在$t = 70T$时刻减为0,进而过渡到倍周期稳定阶段.在倍周期稳定阶段,管内颗粒柱高度以$2T$为周期波动,管内颗粒柱平均高度为 一稳定值,即$\langle z_{\rm in}-z_{\rm out} \rangle \approx 221$ mm.由图还可以看出,管外容器内颗粒表面高度波动幅度很小,与管内颗粒表面高度波动幅度相比可以忽略不计,管内颗粒柱高度随时间演变的特性和管内颗粒表面高度演变特性一致.此外,对比文献[10]给出的颗粒毛细效应中管内颗粒柱高度演变曲线可知,容器几何参数和振动条件等对管内颗粒柱高度随时间演变的周期转变、颗粒最终毛细上升高度和速度等有着重要影响,其影响机理和影响规律有待进一步研究.

图5

图5

管内颗粒柱高度随时间的演变

Fig.5

Evolution of height of granular column in the tube with time

2.3 管内颗粒速度场

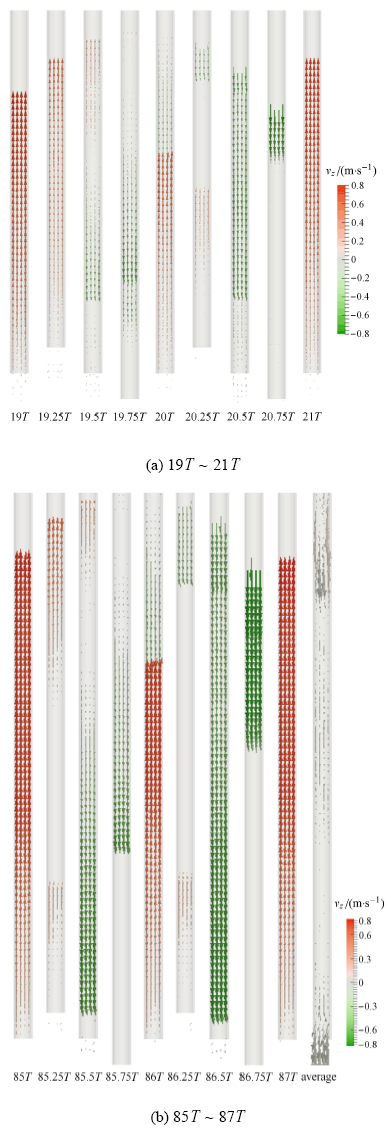

为探明颗粒毛细效应动力学行为的细节信息,对倍周期上升阶段$t = 19T \sim 21 T$时段和倍周期稳定阶段$t = 85T \sim 87T$时段不同时刻管内颗粒平均速度分布进行求解,分别得到两个时段管内颗粒 速度场随时间的演变,如图6所示.由图6(a)可见,$t = 19T$时刻,管以最大速度由平衡位置($z_{\rm b} = 0$)向上运动,由于管内壁摩擦引起的剪切力作用,管内颗粒也向上运动,然而管内颗粒运动速度并不相同,高度越大颗粒运动速度越大,颗粒呈现膨胀状态.$t = 19T \sim 19.25T$时段内,管减速向上运动,$t = 19.25T$时刻,管到达向上的最大位移处($z_{\rm b} = A)$,而颗粒由于惯性,克服壁面剪切力和重力作用,继续向上运动,颗粒速度仍然保持随高度上升而增大的特征.$t = 19.25T \sim 19.5T$时段内,管向下做加速运动,产生向下的壁面剪切力,引起管内颗粒做减速运动,下层颗粒速度较低,速度先减为0继而加速向下运动,上层颗粒速度较高,仍然能够维持向上的速度,产生自下而上传播的速度波,$t = 19.5$时刻的速度场反映了这一特性.$t =19.5 T \sim 19.75 T$时段内,管由平衡位置开始减速向下运动,下层向下运动的颗粒进一步加速,上层向上运动的颗粒则减速至0后开始向下运动,速度波传播使得低填充率区进一步扩大,形成$t = 19.75T$时刻所示的速度场.$t =19.75 T \sim 20T$时段内,管加速向上运动,下层颗粒由于与管之间的速度差更大,因而受到更大的壁面剪切力作用,速度很快减小为0,并转而向上运动,上层颗粒受速度波的影响,填充率较低,壁面剪切力较弱,因而主要受重力作用发生沉降,在$t=20T$时刻形成上层颗粒向下运动、下层颗粒向上运动的速度分布特征,颗粒进入压缩状态. 接着,管开始下一个周期的振动.在$20T \sim 20.25 T$时段内,管减速上升,管内上层颗粒向下的速度波与下层颗粒向上的速度波锋面相遇,颗粒发生碰撞,导致$t=20.25T$时刻管中部颗粒速度几乎为0. 在$20.25T \sim 20.5T$时段内,管加速下降,向下的壁面剪切力和重力共同作用下,颗粒具有较大的向下加速度,因此迅速加速下降,产生$t=20.5T$时刻的速度场. 在$20.5T \sim 20.75T$时段内,管减速下降,管内向下运动的颗粒和容器内颗粒的碰撞,使得管内大部分区域颗粒速度几乎为0,容器内通过对流作用传输到管下端的颗粒进入管内,在$t = 20.75T$时刻压缩过程结束. 在$ 20.75T \sim 21T$时段内,管加速上升,由于此前管内颗粒的压缩效应,颗粒填充率高,管和颗粒间相互作用力很强,在向上的壁面剪切力带动下新进入管内的颗粒连同管内原有颗粒一起克服重力而随管上升,管内颗粒数目增大.对比图6(b)和图6(a)发现,两时段内管内颗粒速度场随时间的演变类似,但也存在不同之处,具体表现在:经过2$T$时间,倍周期稳定阶段的颗粒柱高度不变,而倍周期上升阶段管内颗粒柱高度明显上升;0.25$T$后,即$t= 19.25T$和$t = 85.25T$时刻,管内颗粒速度场存在差异.究其原因是:在倍周期稳定阶段,管内颗粒柱在管下端产生的压力与管外颗粒在同一位置产生的压力相平衡,因而管向上运动时($t=85T \sim 85.25T$)颗粒由容器内向管内的传输被完全抑制,使得管内颗粒量保持不变,颗粒传输特性的改变引起了管内颗粒速度场的改变.图6(b)同时 给出了$t= 85T \sim 87T$时段管内颗粒平均速度场,可见颗粒平均速度接近于0,这也表明颗粒运动处于稳定阶段.

图6

图6

管内颗粒速度场随时间的演变

Fig.6

Evolution of particle velocity field in the tube with time

2.4 管内颗粒填充率

随着管的振动,管内颗粒发生膨胀和压缩,将引起颗粒填充率随位置和时间发生变化. 图7给出了倍周期上升阶段$t = 19 T \sim 21T$时段与倍周期稳定阶段$t = 85 T \sim 87T$时段典型时刻管内颗粒填充率分布. 对比图7(a)中$t= 19T$和21$T$时刻颗粒填充率分布可知,$z < 123$ mm时,颗粒填充率均保持在很高的水平,且二者很接近;$z > 123$ mm时,$t = 21T$时刻高填充率一直维持到$z = 138$ mm,而$t = 19T$时刻由于已超出管内颗粒柱表面,颗粒填充率急剧下降为0;与此不同,$t = 20T$时刻颗粒填充率在$z = 103.5$ mm时出现一个谷值,填充率分布呈现上层颗粒较为松散而下层颗粒较为致密的分层特性. 对比$t = 19.5T$和20.5$T$时刻颗粒填充率分布可知,除在15 mm$ \leqslant z \leqslant$ 42 mm出现共同的低填充率区外,$t = 19.5T$时刻在105 mm$ \leqslant z \leqslant$ 117 mm也存在一个低填充率区,该低填充率区是由于速度波的传播引起的.由图7(b)可知,倍周期稳定阶段的填充率分布规律与倍周期上升阶段相似,但由于倍周期稳定阶段管向上运动时容器内颗粒向管内的传输被完全抑制,使得管底部颗粒填充率低于倍周期上升阶段. 图7(b)中同时给出了$t = 85T \sim 87T$内颗粒平均填充率,可见平均填充率在$z < 207$ mm时维持在0.45以上,$z > 207$ mm时由于颗粒柱高度的波动性造成颗粒的缺失,且高度越大,颗粒缺失越严重,因而平均填充率随高度上升而迅速下降.图7中结果还表明,颗粒填充率的变化呈现明显的周期性,与颗粒速度场(见图6)的变化周期一致.

图7

2.5 由容器内传输到管内的颗粒占比

为了探究颗粒由容器向管内的传输特性,按照初始位置,将颗粒分为两类:一类为初始位置在管所经过的区域内 ($r<R_{\rm tube}$且$z >-A$, 其中$ R_{\rm tube}=d/z$为管的半径)的颗粒,另一类为初始位置在该区域以外的容器内颗粒,分别记为管内颗粒和容器内颗粒.将管内颗粒所在区域划分为4个等体积的子区域,分别对应于($r/R_{\rm tube})^{2} < 0.25$,$0.25 \leqslant (r/R_{\rm tube})^{2} < 0.5$,$0.5 \leqslant (r/R_{\rm tube})^{2} < 0.75$和$0.75 \leqslant (r/R_{\rm tube})^{2} < 1$,再将每个子区域划分为高度$\Delta z = 5d_{\rm p}$的若干个单元. 在相应的时刻,统计每个单元内两类颗粒的数目,分别记为$N_{\rm in}$和$N_{\rm out}$,进而计算由容器传输到管内的颗粒占比$P_{\rm out} = N_{\rm out} / (N_{\rm in }+N_{\rm out})$.

图8给出了容器内传输到管内的颗粒占比分布情况,其中,图8(a)~图8(d)依次对应于单周期上升阶段的$t = 6T$时刻、倍周期上升阶段的$t = 20T$时刻、倍周期稳定阶段的$t = 85T$、倍周期稳定阶段$t = 85T \sim 87T$的平均值.在$t = 6T$时刻,随着高度上升,$P_{\rm out}$趋于减小,$z > 62$ mm的管段内颗粒全部为初始时刻位于管内的颗粒;在$z < 62$ mm的管段内,相同高度位置,越靠近管壁,$P_{\rm out}$越大,这是因为管向上加速运动时,管内颗粒向上运动,壁面剪切力作用使得管内存在径向速度梯度,壁面附近颗粒速度高,中心区域颗粒速度低,管底部形成的空穴在管中心轴线区域较小、在管壁面附近区域较大,容器内颗粒由对流传输到管底部的颗粒更多地出现在离管中心轴线较远的区域,进而在下一个管振动周期进入管内. 与$t= 6T$时刻相比,在$t = 20T$时刻,同一单元内$P_{\rm out}$有所增大,同时$P_{\rm out }>0$的区域明显增加,这与颗粒由容器内传输到管内使得颗粒柱高度上升相一致. 在$t = 85T$时刻,$z < 107$ mm的管段内几乎全部为由容器内传输到管内的颗粒;$z > 107$ mm的管段内,随着高度的上升,$P_{\rm out}$趋于减小,并且与$t = 6T$,$t = 20T$时不同,$P_{\rm out }=0$的管段不再存在,这表明管内上层颗粒出现了充分混合.由图还可以看出,在倍周期稳定阶段,颗粒柱上层呈现出越靠近管壁,$P_{\rm out}$越小的特征,这与颗粒上升阶段的分布相反,这一特点加之颗粒的混合特性充分说明了在上层存在颗粒对流现象.

图8

图8

由容器传输到管内的颗粒占比分布情况

Fig.8

Distribution of percentage of particles transported from the container into the tube

3 结 论

基于离散元方法对颗粒毛细效应中的动力学行为开展数值模拟研究,再现了实验中观察到的竖直振动管内颗粒毛细效应的过程.在此基础上,给出了颗粒毛细效应过程中管内颗粒柱高度随时间演变的规律,分析了管内颗粒速度场和填充率,获得了容器内向管内传输的颗粒占比分布特性. 通过本文研究,得到如下结论:

(1)管内颗粒柱高度随时间的演变呈现单周期上升、倍周期上升和倍周期稳定3个阶段,在倍周期上升阶段颗粒柱上升速度逐渐减小,平缓过渡到稳定阶段;这一演变历程受到颗粒系统参数的影响.

(2)管内不同高度位置颗粒的运动并不同步,随着管的振动,管内存在速度波,速度波的传播引起管内颗粒出现膨胀和压缩交替的情况,从而管内颗粒填充率随时间发生周期性波动.

(3)在颗粒毛细效应的不同阶段,不同径向位置由容器内传输到管内的颗粒占比不同,在上升阶段,越接近管壁由容器内传输到管内的颗粒占比越大;在稳定阶段,管内上层颗粒的对流运动引起越接近管壁由容器内传输到管内的颗粒占比越小.

参考文献

Interplay of air and sand: Faraday heaping unravelled

Scaling of convective velocity in a vertically vibrated granular bed

61The velocity scaling of granular convection is developed experimentally.61The relevant scaling parameters for granular convection are obtained.61Granular convective structure depends on the vibrational frequency than the maximum acceleration.

Transport properties and segregation phenomena in vibrating granular beds

Study of the accumulation of grains in a two dimensional vibrated U-tube without interstitial fluid

We present an experimental and computational study using Molecular Dynamics simulations of the development of an accumulation of grains in one side of a two dimensional U-tube under vertical vibrations. Studying the evolution of the height difference between the columns of grains in the branches of the tube, we found that it reaches a saturation value after vibrating for some time. We obtain that this saturation value is the same if the simulation or experiment start with the arms leveled or with a large initial height difference. We explore computationally the effect of the width of the tube, the density of the grains and the coefficient of restitution between the grains and the wall on the value of the saturation. We obtain a value of the width of the tube for which the saturation value reaches a maximum, and show that the transport of grains between arms is favored for low grain densities and high grain-wall restitution coefficient.

Improved model for the U-tube granular instability: Analytical solution and delayed coupling

The U-tube granular instability is understood as a tendency to increase of the height difference Δh between the granular material in both branches of a vertically vibrated U-tube. Δh has been reported to increase exponentially with time for a certain range of experimental parameters. A simple model based on a cyclic fluid/solid response of the granular material has been used to explain the dependence of the exponential growth rate γ with the maximum dimensionless acceleration Γ of vibration, at least within a certain range of applicability. We introduce an analytic solution of the model and use it to discuss the effect of several parameters on γ. The original model could not predict an abrupt decrease of γ observed at large Γ. In this work we show how considering a Γ dependent delayed coupling between the granular material and the vibrating tube allows the model to describe the rapid decrease of γ seen at large Γ and provides a new perspective to understand this behavior.

Partition instability in water-immersed granular systems

It is well known that a system of grains, vibrated vertically in a cell divided into linked columns, may spontaneously move into just one of the columns due to the inelastic nature of their collisions. Here we study the behavior of a water-immersed system of spherical barium titanate particles in a rectangular cell which is divided into two columns, linked by two connecting holes, one at the top and one at the bottom of the cell. Under vibration the grains spontaneously move into just one of the columns via a gradual transfer of grains through the connecting hole at the base of the cell. We have developed numerical simulations that are able to reproduce this behavior and provide detailed information on the instability mechanism. We use this knowledge to propose a simple analytical model for this fluid-driven partition instability based on two coupled granular beds vibrated within an incompressible fluid.

Particle climbing along a vibrating tube: A vibrating tube that acts as a pump for lifting granular materials from a silo

Granular material under the action of gravity flows down an incline tube or plane. This paper presents a phenomenon in which a granular material climbs along a vertically vibrating tube that is partially inserted in a granular silo. In this scenario the final climbing height increases with increasing vibration strength and tube insertion depth. However, the climbing velocity of the granular material does not monotonically increase with the climbing height. A transition height, at which the granular material has the highest climbing velocity, also exists. When the tube vibrates, the force between the tube and the particles varies periodically, thus inducing the directional climbing of particles. By analyzing the forces on the particles, we present a model that is qualitatively consistent with the experimental results.

Effect of hoisting tube shape on particle climbing

61Both the climbing in straight tube (S) and tapered-tip tube (T) have been researched.61The tapered-tip at tube bottom can strengthen particle climbing.61The particles in T tube can directly climb when Γ<Γa or without initial filling.61The climbing in T tube is insensitive to the inserting depth & the hopper shape.

竖直振动管中颗粒的上升运动

<p>通过实验和数值模拟研究了竖直振动管中颗粒的受激运动. 将一直管插入静止的颗粒料层中,并在管内预填充一定高度的颗粒,对直管施加竖直振动. 振动强度较弱时,管内的颗粒在重力作用下向下运动;当振动达到一定的强度时,管内颗粒不下降反而克服重力的作用向上运动,随着振动强度的进一步提高,即使不在管内预填充高于颗粒床层的颗粒,颗粒也会沿着振动管逆重力向上运动. 颗粒的上升高度与运动速度强烈依赖于振动强度. 通过高速相机记录颗粒和直管在单个振动周期内的运动,并结合离散元(DEM)法模拟管内颗粒的受力变化规律,给出了颗粒上升的机理. 此研究对实现散体物料的定向输运提供了一种新方法.</p>

The rising motion of grains in a vibrating pipe

<p>通过实验和数值模拟研究了竖直振动管中颗粒的受激运动. 将一直管插入静止的颗粒料层中,并在管内预填充一定高度的颗粒,对直管施加竖直振动. 振动强度较弱时,管内的颗粒在重力作用下向下运动;当振动达到一定的强度时,管内颗粒不下降反而克服重力的作用向上运动,随着振动强度的进一步提高,即使不在管内预填充高于颗粒床层的颗粒,颗粒也会沿着振动管逆重力向上运动. 颗粒的上升高度与运动速度强烈依赖于振动强度. 通过高速相机记录颗粒和直管在单个振动周期内的运动,并结合离散元(DEM)法模拟管内颗粒的受力变化规律,给出了颗粒上升的机理. 此研究对实现散体物料的定向输运提供了一种新方法.</p>

Origin of granular capillarity revealed by particle-based simulations

DOI: https://doi.org/10.1103/PhysRevLett.118.218001

Vertical motion of particles in vibration-induced granular capillarity

When a narrow tube inserted into a static container filled with particles is subjected to vertical vibration, the particles rise in the tube, much resembling the ascending motion of a liquid column in a capillary tube. To gain insights on the particle dynamics dictating this phenomenon - which we term granular capillarity - we numerically investigate the system using the Discrete Element Method (DEM). We reproduce the dynamical process of the granular capillarity and analyze the vertical motion of the individual particles in the tube, as well as the average vertical velocities of the particles. Our simulations show that the height of the granular column fluctuates in a periodic or period-doubling manner as the tube vibrates, until a steady-state (capillary) height is reached. Moreover, our results for the average vertical velocity of the particles in the tube at different radial positions suggest that granular convection is one major factor underlying the particle-based dynamics that lead to the granular capillarity phenomenon.

竖直振动下颗粒物质的行为模式研究进展

竖直振动下颗粒物质行为模式的研究对化工过程中效率的提升具有重要意义,该研究近年来成为热点,并不断取得新进展。本文将已有竖直振动下颗粒物质行为模式研究归纳为:竖直振动颗粒床中颗粒的行为、竖直振动颗粒床中颗粒沿直管的爬升、竖直振动U形管中颗粒的迁移、静止颗粒床中颗粒沿竖直振动管的爬升,并对相关研究进展进行评述,发现目前对颗粒物质运动规律的认识还不深入,颗粒物质行为模式的内在机理上尚存争议。鉴于离散元方法(DEM)能够获得每一个颗粒的运动信息,从而很好地反映颗粒过程的机理和特性,对竖直振动U形管和竖直振动管中颗粒物质行为模式进行DEM模拟再现;据此提出在今后的研究中应充分发挥DEM的优势,深入研究颗粒行为模式的动力学本质和影响颗粒行为模式的因素,为颗粒输运过程的优化提供理论基础和方法指导。

Research progress on behavior mode of granular matter under vertical vibration

竖直振动下颗粒物质行为模式的研究对化工过程中效率的提升具有重要意义,该研究近年来成为热点,并不断取得新进展。本文将已有竖直振动下颗粒物质行为模式研究归纳为:竖直振动颗粒床中颗粒的行为、竖直振动颗粒床中颗粒沿直管的爬升、竖直振动U形管中颗粒的迁移、静止颗粒床中颗粒沿竖直振动管的爬升,并对相关研究进展进行评述,发现目前对颗粒物质运动规律的认识还不深入,颗粒物质行为模式的内在机理上尚存争议。鉴于离散元方法(DEM)能够获得每一个颗粒的运动信息,从而很好地反映颗粒过程的机理和特性,对竖直振动U形管和竖直振动管中颗粒物质行为模式进行DEM模拟再现;据此提出在今后的研究中应充分发挥DEM的优势,深入研究颗粒行为模式的动力学本质和影响颗粒行为模式的因素,为颗粒输运过程的优化提供理论基础和方法指导。

Nonlinear instability and convection in a vertically vibrated granular bed

The nonlinear instability of the density-inverted granular Leidenfrost state and the resulting convective motion in strongly shaken granular matter are analysed via a weakly nonlinear analysis of the hydrodynamic equations. The base state is assumed to be quasi-steady and the effect of harmonic shaking is incorporated by specifying a constant granular temperature at the vibrating plate. Under these mean-field assumptions, the base-state temperature decreases with increasing height away from the vibrating plate, but the density profile consists of three distinct regions: (i) a collisional dilute layer at the bottom, (ii) a levitated dense layer at some intermediate height and (iii) a ballistic dilute layer at the top of the granular bed. For the nonlinear stability analysis (Shukla & Alam, J. Fluid Mech., vol. 672, 2011b, pp. 147 195), the nonlinearities up to cubic order in the perturbation amplitude are retained, leading to the Landau equation, and the related adjoint stability problem is formulated taking into account appropriate boundary conditions. The first Landau coefficient and the related modal eigenfunctions (the fundamental mode and its adjoint, the second harmonic and the base-flow distortion, and the third harmonic and the cubic-order distortion to the fundamental mode) are calculated using a spectral-based numerical method. The genesis of granular convection is shown to be tied to a supercritical pitchfork bifurcation from the density-inverted Leidenfrost state. Near the bifurcation point the equilibrium amplitude ( $A_{e}$ ) is found to follow a square-root scaling law, $A_{e}\\sim \\sqrt{{\\it\\Delta}}$ , with the distance ${\\it\\Delta}$ from the bifurcation point. We show that the strength of convection (measured in terms of velocity circulation) is maximal at some intermediate value of the shaking strength, with weaker convection at both weaker and stronger shaking. Our theory predicts that at very strong shaking the convective motion remains concentrated only near the top surface, with the bulk of the expanded granular bed resembling the conduction state of a granular gas, dubbed as a floating-convection state. The linear and nonlinear patterns of the density and velocity fields are analysed and compared with experiments qualitatively. Evidence of 2:1 resonance is shown for certain parameter combinations. The influences of bulk viscosity, effective Prandtl number, shear work and free-surface boundary conditions on nonlinear equilibrium states are critically assessed.

Patterns of convective flow in a vertically vibrated granular bed

61Several kinds of convection roll in a vibrated granular bed are introduced by Γ–f phase diagram.61The phase diagram of convection rolls can be divided into four regions.61The vibration frequency plays a significant role on the number and direction of the rolls.61The grains at different positions collide with the vessel bottom un-synchronously.

Damping behaviors of granular particles in a vertically vibrated closed container

2017 Elsevier B.V. Damping behaviors of granular particles in a quasi-two-dimensional (Q-2D) closed container subjected to vertical vibration are simulated by means of Discrete Element Method (DEM). Phase diagram and damping contour of vibrated granular particles in the amplitude-frequency plane of external excitation are obtained, which indicates six different damping phases of vibrated granular particles. Simulation results also reveal that three suspended states of vibrated granular particles (i.e., Leidenfrost effect, Buoyancy convection and Bidirectional Leidenfrost effect) display the higher damping capacity, and especially granular Leidenfrost effect demonstrates the optimal damping effect. Furthermore, the dissipation characteristic of granular Leidenfrost effect is analyzed respectively from the perspective of energy transformation and energy dissipation. The influence of the corresponding parameters (gap clearance, particle diameter and container dimension) on the three high damping suspended phases (HDSPs) of vibrated granular particles is explored. Finally, base on the rheological behavior of vibrated granular particles, a visualization method for evaluating the granular damping effect by DEM simulation is proposed for the first time, which may provide a new idea for designing optimal granular dampers.

Experimental study and analysis on the rising motion of grains in a vertically-vibrated pipe

Previous experimental investigations have shown that when a narrow pipe is inserted into a granular bed and is vibrated vertically but the granular bed is kept still, the grains in the bed can enter the pipe and rise against gravity along the pipe and finally stabilized at a certain height. The growth velocity and final stable height of the grain column inside the pipe can be controlled by varying the vibration conditions. In this paper, we discuss those experimental findings. We establish a mathematic relation between the grain column height(h) and time(t), and by using the relation we discuss the change of the growth velocity( dh/ dt) and acceleration( d2h/ dt2) with t and h, respectively. We also analyze the mechanism of the rising motion of the grains during vibration. Furthermore, we derive a theoretical expression for describing the final stable height(h st), which shows that the main factors influencing the height are vibration strength(Γ), bulk density of grains,inner diameter of the pipe, and vibration frequency, and that h st increases nonlinearly in the presence of air and linearly in a vacuum environment with increasing Γ.

Particles climbing along a vertically vibrating tube: Numerical simulation using the discrete element method (DEM)

It has been reported experimentally that granular particles can climb along a vertically vibrating tube partially inserted inside a granular silo. In this paper, we use the Discrete Element Method (DEM) available in the Multiphase Flow with Interphase eXchanges (MFIX) code to investigate this phenomenon. By tracking the movement of individual particles, the climbing mechanism was illustrated and analyzed. The numerical results show that a sufficiently high vibration strength is needed to form a low solids volume fraction region inside the lower end of the vibrating tube, a dense region in the middle of the tube, and to bring the particles outside from the top layers down to fill in the void. The results also show that particle compaction in the middle section of the tube is the main cause of the climbing. Consequently, varying parameters which influence the compacted region, such as the restitution coefficient, change the climbing height.

Effects of vibration parameters and pipe insertion depth on the motion of particles induced by vertical vibration

PACS number: 45.70.MG - granular flow

尼龙粉末在SLS预热温度下的离散元模型参数确定及其流动特性分析

Determination of discrete element model contact parameters of nylon powder at SLS preheating temperature and its flow characteristics

粒料固有各向异性的离散元模拟与细观分析

料在摊铺后形成的颗粒定向排列将导致其力学性质的固有各向异性. 依据粒料的实际不规则形状, 构建了可模拟粒间咬合嵌挤作用的三维离散元复杂形状颗粒; 生成了5 种不同沉积方向的各向异性试件和1种各向同性试件, 对比了各试件在三轴压缩试验中的宏观力学特性差异; 引入组构张量以量化各向异性程度, 利用玫瑰图表达接触法向与接触力的分布特征, 探究了粒料各向异性的细观发展规律. 结果表明: 颗粒长轴愈趋向水平排布, 峰值应力比愈大, 剪缩与剪胀程度愈明显; 相较于各向同性试件, 沉积角$\theta$为$0^\circ$时, 峰值应力比和最大体积压缩应变分别提高了12.6\%和18.8\%, 其原因在于加载过程中颗粒旋转和滑动百分比更小, 内部调整时间更短、更易被剪密; 固有各向异性对颗粒法向接触力分布的影响不大, 但显著影响接触法向分布特征; 剪切过程中, $\theta$为$90^\circ$时的接触法向各向异性系数先快速减小后逐渐增大, 而$\theta$为$0^\circ$到$60^\circ$时则呈现出增大后稍有回落或趋于稳定的趋势, 且$\theta$ 愈小的试件各向异性系数增大愈快.

Simulation and micro-mechanics analysis of inherent anisotropy of granular by distinct element method

料在摊铺后形成的颗粒定向排列将导致其力学性质的固有各向异性. 依据粒料的实际不规则形状, 构建了可模拟粒间咬合嵌挤作用的三维离散元复杂形状颗粒; 生成了5 种不同沉积方向的各向异性试件和1种各向同性试件, 对比了各试件在三轴压缩试验中的宏观力学特性差异; 引入组构张量以量化各向异性程度, 利用玫瑰图表达接触法向与接触力的分布特征, 探究了粒料各向异性的细观发展规律. 结果表明: 颗粒长轴愈趋向水平排布, 峰值应力比愈大, 剪缩与剪胀程度愈明显; 相较于各向同性试件, 沉积角$\theta$为$0^\circ$时, 峰值应力比和最大体积压缩应变分别提高了12.6\%和18.8\%, 其原因在于加载过程中颗粒旋转和滑动百分比更小, 内部调整时间更短、更易被剪密; 固有各向异性对颗粒法向接触力分布的影响不大, 但显著影响接触法向分布特征; 剪切过程中, $\theta$为$90^\circ$时的接触法向各向异性系数先快速减小后逐渐增大, 而$\theta$为$0^\circ$到$60^\circ$时则呈现出增大后稍有回落或趋于稳定的趋势, 且$\theta$ 愈小的试件各向异性系数增大愈快.

石英玻璃圆环高速膨胀碎裂过程的离散元模拟

采用离散元算法模拟了石英玻璃圆环受到外加动态载荷时的力学行为.首先基于flat-jointed粘结模型,通过标准的单轴拉压、三点弯曲等数值实验来标定了石英玻璃的微观参数.在此模型基础上,数值模拟再现了石英玻璃圆环在不同应变率下的膨胀碎裂过程.为定量分析数值模拟结果,需要准确确定圆环的碎裂发生时刻.模拟发现:伴随着石英玻璃圆环的断裂,圆环外表面粒子径向膨胀速度的时程曲线会发生突然升高然后下降的跳动;详细分析表明,这种跳动源自周向的脆性断裂诱发的卸载波(周向拉伸应力急剧下降)以及伴随而来的泊松膨胀,这种径向速度跳动现象为实验中检测脆性断裂发生时刻提供了可能.进一步的数值研究表明:(1)石英玻璃圆环的断裂应变随着应变率的提高而增大,与韧性金属材料的膨胀环实验结果一致;(2)石英玻璃圆环的碎片平均质量随着应变率的增大而减小;(3)数值计算获得的碎片平均尺寸与已有的理论和实验结果比较吻合.利用液压膨胀环实验装置对石英玻璃圆环进行了验证性实验,回收得到的碎片形貌及碎片个数与数值模拟的结果基本一致.

Discrete element simulations of the high velocity expansion and fragmentation of quartz glass rings

采用离散元算法模拟了石英玻璃圆环受到外加动态载荷时的力学行为.首先基于flat-jointed粘结模型,通过标准的单轴拉压、三点弯曲等数值实验来标定了石英玻璃的微观参数.在此模型基础上,数值模拟再现了石英玻璃圆环在不同应变率下的膨胀碎裂过程.为定量分析数值模拟结果,需要准确确定圆环的碎裂发生时刻.模拟发现:伴随着石英玻璃圆环的断裂,圆环外表面粒子径向膨胀速度的时程曲线会发生突然升高然后下降的跳动;详细分析表明,这种跳动源自周向的脆性断裂诱发的卸载波(周向拉伸应力急剧下降)以及伴随而来的泊松膨胀,这种径向速度跳动现象为实验中检测脆性断裂发生时刻提供了可能.进一步的数值研究表明:(1)石英玻璃圆环的断裂应变随着应变率的提高而增大,与韧性金属材料的膨胀环实验结果一致;(2)石英玻璃圆环的碎片平均质量随着应变率的增大而减小;(3)数值计算获得的碎片平均尺寸与已有的理论和实验结果比较吻合.利用液压膨胀环实验装置对石英玻璃圆环进行了验证性实验,回收得到的碎片形貌及碎片个数与数值模拟的结果基本一致.

Model for collisions in granular gases

Abstract: We propose a model for collisions between particles of a granular material and calculate the restitution coefficients for the normal and tangential motion as functions of the impact velocity from considerations of dissipative viscoelastic collisions. Existing models of impact with dissipation as well as the classical Hertz impact theory are included in the present model as special cases. We find that the type of collision (smooth, reflecting or sticky) is determined by the impact velocity and by the surface properties of the colliding grains. We observe a rather nontrivial dependence of the tangential restitution coefficient on the impact velocity.

Collision of viscoelastic spheres: Compact expressions for the coefficient of normal restitution

The coefficient of restitution of colliding viscoelastic spheres is known analytically as a complete series expansion in terms of the impact velocity where all (infinitely many) coefficients are known. While being analytically exact, this result is not suitable for applications in efficient event-driven molecular dynamics (eMD) or direct simulation Monte Carlo (DSMC) methods. Based on the analytic result, here we derive expressions for the coefficient of restitution that allow for application in efficient eMD and DSMC simulations of granular systems.

A discrete numerical model for granular assemblies

Physical test of a particle simulation model in a sheared granular system

We report a detailed comparison of a slow gravity-driven sheared granular flow with a discrete-element simulation performed in the same geometry. In the experiments, grains flow inside a silo with a rectangular cross section and are sheared by a rough boundary on one side and smooth boundaries on the other sides. Individual grain position and motion are measured using a particle index-matching imaging technique where a fluorescent dye is added to the interstitial liquid which has the same refractive index as the glass beads. The simulations use a Cundall-Strack contact model between the grains using contact parameters that have been used in many other previous studies and ignore the hydrodynamic effects of the interstitial liquid. Computations are performed to understand the effect of particle coefficient of friction, elasticity, contact model, and polydispersity on mean flow properties. We then perform a detailed comparison of the particle fluctuation properties as measured by the displacement probability distribution function and the mean square displacement. All in all, our study suggests a high level of quantitative agreement between the simulations and experiments.

Attractive particle interaction forces and packing density of fine glass powders

Abstract We study the packing of fine glass powders of mean particle diameter in the range (4-52) 脦录m both experimentally and by numerical DEM simulations. We obtain quantitative agreement between the experimental and numerical results, if both types of attractive forces of particle interaction, adhesion and non-bonded van der Waals forces are taken into account. Our results suggest that considering only viscoelastic and adhesive forces in DEM simulations may lead to incorrect numerical predictions of the behavior of fine powders. Based on the results from simulations and experiments, we propose a mathematical expression to estimate the packing fraction of fine polydisperse powders as a function of the average particle size.

Assessment of rolling resistance models in discrete element simulations

Modelling rolling resistance of particles in discrete element simulations can be important for producing satisfactory predictions. A careful evaluation of the commonly used models revealed significant shortcomings that were unreported. Figure below shows kinetic energy dissipation in a sandpile for different models where the proposed model shows a significant improvement.

Force schemes in simulations of granular materials

三方程线性弹性——阻尼DEM模型及碰撞参数确定

建立了一种考虑法向接触力、切向接触力(含静滑动摩擦力及动滑动摩擦力)和力矩(含由切向力产生的力矩及静滚动摩擦力矩和动滚动摩擦力矩)的三方程线性弹性-阻尼离散单元模型,并将该模型应用到颗粒物料的三维数值模拟中,讨论了模型中几个重要碰撞参数--刚性系数、阻尼系数及摩擦系数的选择及其对计算结果的影响,同时也探讨了时间步长等计算参数对模拟结果的影响.为了验证算法和参数选择的正确性,本文对几个有代表性的颗粒系统进行了数值试验研究,并对计算结果进行了细致的分析,验证了新模型和参数选择的正确性.

Three-equation linear spring-dashpot DEM model and the determination of contact parameters

建立了一种考虑法向接触力、切向接触力(含静滑动摩擦力及动滑动摩擦力)和力矩(含由切向力产生的力矩及静滚动摩擦力矩和动滚动摩擦力矩)的三方程线性弹性-阻尼离散单元模型,并将该模型应用到颗粒物料的三维数值模拟中,讨论了模型中几个重要碰撞参数--刚性系数、阻尼系数及摩擦系数的选择及其对计算结果的影响,同时也探讨了时间步长等计算参数对模拟结果的影响.为了验证算法和参数选择的正确性,本文对几个有代表性的颗粒系统进行了数值试验研究,并对计算结果进行了细致的分析,验证了新模型和参数选择的正确性.

Damping and particle mass in DEM simulations under gravity

Models, algorithms and validation for opensource DEM and CFD-DEM

We present a multi-purpose CFD-DEM framework to simulate coupled fluid-granular systems. The motion of the particles is resolved by means of the Discrete Element Method (DEM), and the Computational Fluid Dynamics (CFD) method is used to calculate the interstitial fluid flow. We first give a short overview over the DEM and CFD-DEM codes and implementations, followed by elaborating on the numerical schemes and implementation of the CFD-DEM coupling approach, which comprises two fundamentally different approaches, the unresolved CFD-DEM and the resolved CFD-DEM using an Immersed Boundary (IB) method. Both the DEM and the CFD-DEM approachare successfully tested against analytics as well as experimental data.